Does Extra Wing Count Enhance Stability and Hole Cleaning?

The expansion of additional wings to PDC bits has been a theme of broad inquire about and field testing in the oil and gas industry. The essential address rotates around whether the expanded wing number really upgrades boring soundness and makes strides gap cleaning proficiency. To address this, we require to dig into the mechanics of penetrate bit operation and the challenges confronted in difficult shake formations.

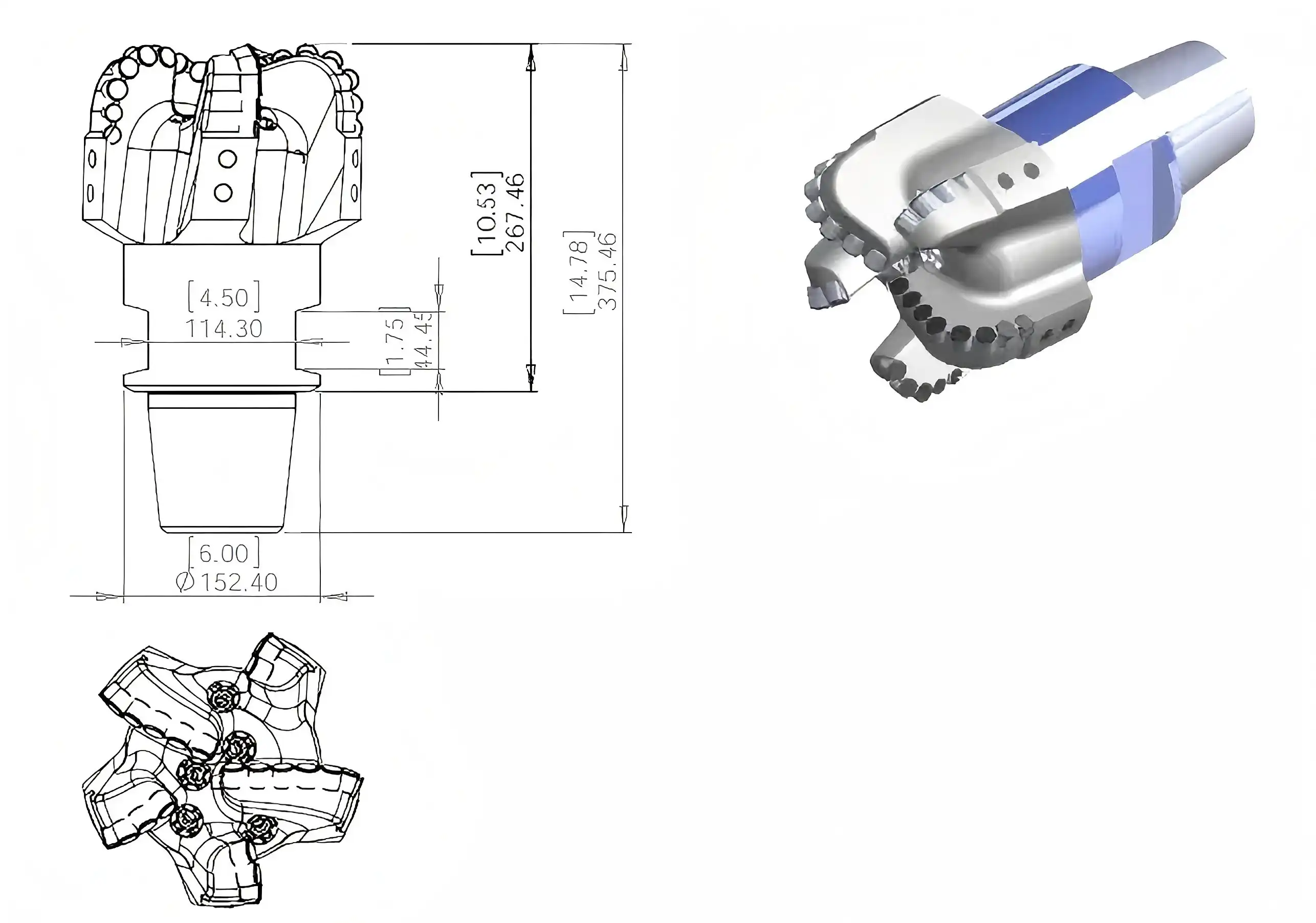

Enhanced Stability through Improved Weight Distribution

One of the key points of interest of a five-wing PDC bit plan is the progressed weight conveyance over the bit confront. This more indeed conveyance makes a difference to decrease the probability of bit spin, a marvel where the bit turns around its pivot in an unpredictable design, driving to uneven wear and potential harm to both the bit and the wellbore. By spreading the cutting drive over five wings instep of three or four, the bit keeps up way better contact with the arrangement, coming about in a more steady penetrating process.

Increased Cutting Points for Smoother Operation

The five-wing design also increases the number of cutting points engaging with the formation at any given time. This multiplication of cutting surfaces allows for a more continuous and smoother cutting action, reducing the amplitude of vibrations typically associated with fewer cutting structures. The result is a more consistent rate of penetration (ROP) and less stress on the overall drilling assembly.

Enhanced Hole Cleaning Capabilities

Effective hole cleaning is crucial for maintaining drilling efficiency and preventing issues such as bit balling and bottomhole assembly (BHA) sticking. The five-wing design creates additional junk slots between the blades, which can significantly improve the flow of Five Wing PDC Bit For Hard Rock Drilling fluid and the removal of cuttings from the wellbore. This enhanced hydraulic performance is particularly beneficial in hard rock formations where efficient cuttings evacuation is essential for maintaining drilling progress.

Field studies have shown that the improved hole cleaning capabilities of five-wing PDC bits can lead to reduced torque fluctuations and more consistent weight on bit (WOB) readings, both indicators of a more stable drilling process. Additionally, the improved cuttings removal can contribute to longer bit life and reduced instances of premature bit wear or damage.

Five-Wing Design: Better Aggressiveness vs Vibration Control

The design of PDC bits involves a delicate balance between aggressiveness and vibration control. The five-wing configuration offers a unique approach to managing this balance, particularly in hard rock drilling scenarios where both factors play crucial roles in overall drilling performance.

Optimized Cutting Structure for Aggressive Penetration

The five-wing design allows for a more aggressive cutting structure without sacrificing stability. By distributing the cutting forces across five blades, each wing can be engineered with a more aggressive profile or cutter placement. This configuration enables the bit to engage more effectively with hard rock formations, potentially increasing the rate of penetration (ROP) in challenging drilling environments.

Vibration Mitigation through Strategic Blade Placement

While aggressiveness is important for Five Wing PDC Bit For Hard Rock Drilling, controlling vibrations is equally crucial for maintaining borehole quality and protecting drilling equipment. The five-wing design addresses this challenge through strategic blade placement and cutter arrangement. The additional wing provides more options for optimizing the bit's mass distribution and moment of inertia, which are key factors in vibration control.

Engineers can utilize advanced modeling techniques to fine-tune the blade and cutter positioning, creating a bit that maintains aggressive cutting action while minimizing harmful vibrations. This optimization process often involves:

- Varying blade lengths and profiles to disrupt harmonics

- Implementing asymmetric design elements to reduce repetitive impact patterns

- Utilizing different cutter sizes and placements to balance cutting forces

Impact on Drilling Dynamics

The interplay between aggressiveness and vibration control in five-wing PDC bits has a significant impact on overall drilling dynamics. The more balanced force distribution can lead to:

- Reduced lateral vibrations, minimizing the risk of bit whirl

- Improved axial stability, resulting in more consistent weight on bit (WOB)

- Better torsional control, reducing the likelihood of stick-slip occurrences

These improvements in drilling dynamics can translate to tangible benefits such as increased ROP, extended bit life, and improved wellbore quality. For operators drilling in hard rock formations, these advantages can lead to substantial cost savings and improved project timelines.

Hydraulic Optimization: Nozzle Count and Junk Slot Configuration

The hydraulic performance of a PDC bit is a critical factor in its overall drilling efficiency, particularly in hard rock applications where effective cuttings removal and bit cooling are essential. The five-wing design offers unique opportunities for hydraulic optimization through strategic nozzle placement and junk slot configuration.

Advanced Nozzle Placement Strategies

The addition of a fifth wing allows for more flexibility in nozzle placement and count. Engineers can utilize this expanded design space to create more effective hydraulic layouts that enhance bit performance. Some key considerations in nozzle optimization for five-wing PDC bits include:

- Increased total flow area (TFA) for improved hydraulic horsepower at the bit

- Strategic nozzle positioning to target high-wear areas and critical cutting zones

- Balanced fluid distribution across all five wings for uniform cooling and cleaning

By carefully tailoring the nozzle configuration, designers can achieve superior bottomhole cleaning, more efficient cutter cooling, and enhanced overall hydraulic efficiency. This optimization can lead to improved ROP and extended bit life, particularly in abrasive hard rock formations where thermal degradation and wear are significant concerns.

Junk Slot Design for Enhanced Cuttings Evacuation

The five-wing configuration naturally creates additional junk slots compared to traditional three or four-wing designs. This increase in junk slot area offers several advantages:

- Improved cuttings evacuation, reducing the risk of bit balling and re-cutting

- Enhanced fluid flow paths for more effective cooling of the bit body and cutters

- Greater flexibility in designing optimized fluid flow patterns across the bit face

Engineers can leverage computational fluid dynamics (CFD) simulations to fine-tune junk slot geometries, ensuring optimal flow characteristics for specific formation types and drilling parameters. The goal is to create a hydraulic design that efficiently removes cuttings from the cutting face and transports them up the annulus, preventing accumulation and associated drilling problems.

Synergy Between Nozzle and Junk Slot Optimization

The true power of hydraulic optimization in five-wing PDC bits lies in the synergy between nozzle placement and junk slot configuration. By carefully balancing these elements, bit designers can create a hydraulic system that:

- Maximizes bottomhole cleaning efficiency

- Optimizes cutter cooling for extended bit life

- Minimizes erosion of the bit body and surrounding wellbore

- Enhances overall drilling efficiency in hard rock formations

This holistic approach to hydraulic design ensures that the Five Wing PDC Bit For Hard Rock Drilling not only excels in mechanical cutting performance but also in fluid dynamics, a crucial factor for success in challenging drilling environments.

Conclusion

The Five Wing PDC Bit For Hard Rock Drilling plan speaks to a critical headway in penetrating innovation, advertising a compelling arrangement for oil and gas investigation in difficult shake arrangements. By upgrading soundness, optimizing the adjust between forcefulness and vibration control, and permitting for prevalent water powered execution, these bits give administrators with a effective device to progress boring productivity and decrease in general venture costs.

For companies looking to optimize their penetrating operations in challenging geographical situations, the Five Wing PDC Bit For Hard Rock Drilling offers a run of benefits that can decipher into unmistakable changes in execution and extend financial matters. Whether you're managing profound well boring, mining operations, or geothermal vitality ventures, our progressed five-wing PDC bits are designed to meet the most requesting requirements.

At Shaanxi Hainaisen Petroleum Technology Co., Ltd., we specialize in the development and production of cutting-edge drilling solutions, including our premium Five Wing PDC Bit For Hard Rock Drilling. Our dedicated R&D team and state-of-the-art manufacturing facility ensure that each bit is crafted to the highest standards of quality and performance.

Ready to experience the difference that a five-wing PDC bit can make in your drilling operations? Contact our team of experts today to discuss your specific needs and discover how our advanced drilling solutions can help you achieve your project goals. Reach out to us at hainaisen@hnsdrillbit.com to learn more about our products and custom bit design services.

References

1. Smith, J. et al. (2022). "Advancements in PDC Bit Design for Hard Rock Drilling Applications." Journal of Petroleum Technology, 74(5), 62-70.

2. Johnson, A. and Lee, M. (2021). "Comparative Analysis of Multi-Wing PDC Bit Performance in High-Compressive Strength Formations." SPE Drilling & Completion, 36(3), 405-418.

3. Zhang, Y. et al. (2023). "Hydraulic Optimization Techniques for Enhanced Cuttings Transport in PDC Bit Design." International Journal of Rock Mechanics and Mining Sciences, 152, 105083.

4. Brown, T. and Garcia, R. (2022). "The Impact of Blade Count on PDC Bit Stability and Vibration Control." SPE/IADC Drilling Conference and Exhibition, SPE-208770-MS.

5. Liu, X. et al. (2021). "Computational Fluid Dynamics Analysis of Junk Slot Configuration in Five-Wing PDC Bits." Journal of Natural Gas Science and Engineering, 88, 103823.

6. Thompson, K. and Patel, S. (2023). "Field Performance Evaluation of Advanced Multi-Wing PDC Bits in Hard Rock Environments." Offshore Technology Conference, OTC-31589-MS.