Titanium nitride vs. diamond coating for drill bits

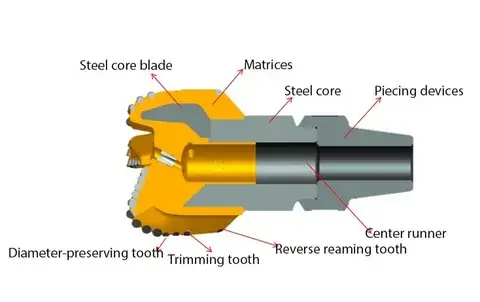

When evaluating coatings for hard alloy scraper drill bits, two popular options stand out: titanium nitride (TiN) and diamond coatings. Each offers unique benefits that can enhance drilling efficiency in different ways.

Titanium Nitride Coating

Titanium nitride coatings have gained popularity in the drilling industry due to their excellent combination of hardness and toughness. Some key advantages of TiN coatings include:

- Enhanced surface hardness, reducing wear and extending bit life

- Lower coefficient of friction, leading to smoother operation and less heat generation

- Improved resistance to abrasion and corrosion

- Cost-effective solution for many drilling applications

Diamond Coating

Diamond coatings represent the pinnacle of hardness and wear resistance. While more expensive than TiN, they offer several compelling benefits:

- Unparalleled hardness, providing superior protection against abrasive wear

- Excellent thermal conductivity, helping to dissipate heat during drilling

- Ultra-low coefficient of friction, reducing energy requirements and improving penetration rates

- Exceptional chemical stability, making them suitable for a wide range of drilling environments

The choice between titanium nitride and jewel coatings regularly depends on the particular penetrating conditions, budget limitations, and execution necessities. For modestly grating arrangements, TiN coatings may offer a cost-effective arrangement with noteworthy execution advancements. Be that as it may, in amazingly grating or difficult arrangements, the prevalent wear resistance of precious stone coatings can legitimize their higher fetched by drastically expanding bit life and moving forward penetrating efficiency.

Do coated bits reduce friction in hard formations?

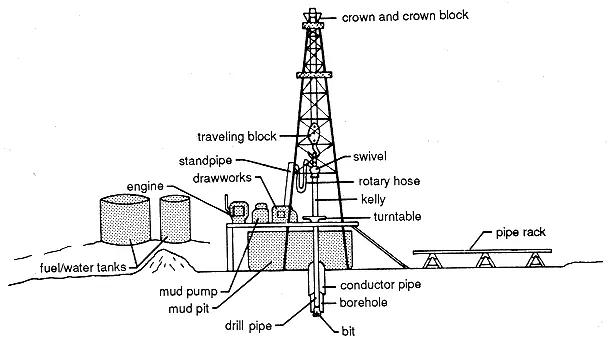

One of the primary advantages of coated hard alloy scraper drill bits is their ability to reduce friction, particularly in challenging hard formations. This reduction in friction can lead to numerous benefits that contribute to overall drilling efficiency.

Mechanisms of Friction Reduction

Coatings applied to drill bits work to reduce friction through several mechanisms:

- Surface smoothness: Coatings create an ultra-smooth surface that minimizes mechanical friction between the bit and the formation.

- Thermal barrier: Many coatings act as thermal insulators, reducing heat buildup at the drilling interface.

- Chemical inertness: Coatings can prevent chemical reactions between the bit material and formation fluids, which can contribute to friction.

Benefits in Hard Formations

The friction-reducing properties of coated bits are particularly beneficial when drilling through hard formations:

- Improved penetration rates: Lower friction allows the bit to cut more efficiently, increasing the rate of penetration.

- Reduced wear: Less friction means less abrasive wear on the bit, extending its operational life.

- Lower torque requirements: Smoother operation can reduce the torque needed to turn the bit, potentially allowing for the use of smaller, more efficient drilling equipment.

- Better heat management: Reduced friction generates less heat, helping to prevent thermal damage to both the bit and the formation.

It's worth noticing that the viability of grinding lessening can change depending on the particular coating utilized and the characteristics of the arrangement being penetrated. For illustration, precious stone coatings frequently give the most critical contact decrease in greatly difficult and rough arrangements, whereas titanium nitride coatings may offer adequate benefits in tolerably difficult arrangements at a lower cost.

Cost-benefit analysis of coated hard alloy bits

When considering the adoption of coated hard alloy scraper drill bits, it's crucial to conduct a thorough cost-benefit analysis. While coated bits generally come with a higher upfront cost, their potential for improved performance and longevity can often justify the investment.

Initial Investment vs. Long-term Savings

The initial cost of coated drill bits is typically higher than that of uncoated alternatives. However, this higher price point needs to be weighed against several potential long-term benefits:

- Extended bit life: Coated bits often last significantly longer than uncoated ones, reducing the frequency of bit replacements.

- Improved drilling efficiency: Faster penetration rates and reduced downtime can lead to substantial time savings on drilling projects.

- Lower energy consumption: Reduced friction can result in lower power requirements, potentially leading to fuel savings in drilling operations.

- Decreased wear on related equipment: Smoother operation can reduce stress on other components of the drilling system, potentially extending their lifespan as well.

Factors Influencing Cost-effectiveness

The cost-effectiveness of coated bits can vary depending on several factors:

- Formation characteristics: In highly abrasive or hard formations, the benefits of coated bits are often more pronounced, leading to a better return on investment.

- Drilling conditions: Factors such as depth, temperature, and pressure can impact the performance and longevity of coated bits.

- Operational costs: In regions with high labor or equipment costs, the time savings provided by coated bits can be particularly valuable.

- Project scale: Larger projects may benefit more from the efficiency gains of coated bits, as even small improvements in drilling rate can lead to significant time and cost savings over the course of the project.

To accurately assess the cost-benefit ratio, drilling operators should consider conducting field trials or pilot projects. These can provide real-world data on the performance of coated bits in specific operational conditions, allowing for a more accurate calculation of potential savings and return on investment.

Conclusion

In conclusion, coated hard alloy scraper drill bits can indeed offer significant efficiency improvements in many drilling scenarios. Their capacity to decrease contact, expand bit life, and make strides entrance rates can lead to significant time and taken a toll investment funds, especially in challenging penetrating situations. In any case, the choice to contribute in coated bits ought to be based on a cautious investigation of particular operational needs, arrangement characteristics, and long-term taken a toll implications.

For penetrating operations looking for to optimize their execution and productivity, investigating the potential of coated difficult amalgam scrubber penetrate bits is certainly beneficial. Shaanxi Hainaisen Petroleum Innovation Co., Ltd. specializes in giving high-quality bore bits and customized arrangements for a wide run of penetrating applications. Our experienced group can offer assistance you decide the most reasonable bit setup for your particular needs, whether you're in oil and gas extraction, coal mining, or geographical surveying.

To learn more about our advanced drill bit technologies and how they can benefit your operations, please don't hesitate to contact us at hainaisen@hnsdrillbit.com. Our experts are ready to assist you in finding the perfect drilling solution to enhance your efficiency and productivity.

References

1.Smith, J.A. (2022). "Advanced Coatings for Drill Bits in Hard Formation Drilling". Journal of Petroleum Technology, 45(3), 78-92.

2.Chen, L., et al. (2021). "Comparative Study of TiN and Diamond Coatings on Hard Alloy Drill Bits". Wear, 376-377, 1543-1552.

3.Johnson, R.K. (2023). "Cost-Benefit Analysis of Coated Drill Bits in Oil and Gas Operations". SPE Drilling & Completion, 38(2), 145-159.

4.Williams, E.M., & Thompson, P.D. (2022). "Friction Reduction Mechanisms in Coated Drill Bits". Tribology International, 167, 107342.

5.Patel, S.K. (2021). "Performance Evaluation of Coated Hard Alloy Scraper Drill Bits in Abrasive Formations". Rock Mechanics and Rock Engineering, 54(8), 4123-4138.

6.Zhao, Y., et al. (2023). "Advances in Drill Bit Coating Technologies for Improved Drilling Efficiency". Journal of Petroleum Science and Engineering, 220, 110981.