Optimizing PDC Bit Design for Coal Formations

The effectiveness of Coal Mining PDC Drill Bits hinges on their ability to navigate the diverse geological conditions encountered in coal seams. Optimizing bit design for these formations requires a nuanced approach that takes into account the specific properties of coal and its surrounding strata.

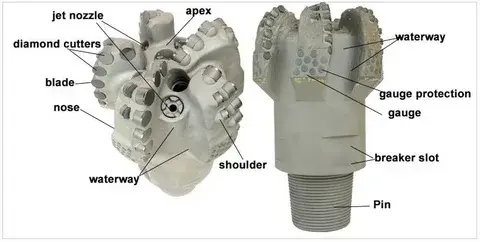

Tailoring Blade Profiles

Blade profiles are fastidiously created to upgrade cutting productivity whereas keeping up solidness. In coal mining applications, a adjust between forceful and preservationist plans is vital. Shallow edge profiles with deliberately put back-rakes in Coal Mining PDC Drill Bits offer assistance avoid bit balling in delicate coal arrangements, whereas more extreme profiles may be utilized for harder interbedded layers.

Cutter Selection and Placement

The choice of PDC cutters is vital in coal penetrating operations. Bigger distance across cutters are frequently favored for their capacity to withstand the grating nature of coal and related minerals. Cutter situation on the bit confront is optimized to guarantee indeed wear and steady execution over changing arrangement hardness.

Junk Slot Configuration

Effective flotsam and jetsam evacuation is basic in coal mining to anticipate bit balling and keep up boring effectiveness. Garbage openings are planned with adequate space and vital situating to encourage the departure of cuttings and avoid distribution, which can lead to diminished rate of infiltration (ROP) and untimely bit wear.

Impact of Cutter Placement on Drilling Efficiency

The arrangement of cutters on a PDC bit significantly influences its drilling efficiency in coal formations. Proper cutter placement enhances penetration rates, bit stability, and overall performance.

Optimizing Cutter Density

Cutter thickness plays an imperative part in deciding the bit's forcefulness and toughness. In coal mining applications, a direct to tall cutter thickness is frequently utilized in Coal Mining PDC Drill Bits to disseminate the cutting powers equitably over the bit confront. This approach makes a difference avoid localized wear and expands the bit's operational life.

Strategic Redundancy

Incorporating excess cutters in high-wear regions guarantees reliable execution indeed as essential cutters involvement wear. This plan logic is especially useful in coal mining, where rough conditions can lead to quickened cutter degradation.

Spiral Placement for Enhanced Stability

Arranging cutters in a winding design over the bit confront advances solidness amid penetrating operations. This arrangement makes a difference disseminate the cutting powers equitably, decreasing vibration and progressing generally penetrating productivity in coal formations.

Hydraulic Channel Innovations in Modern PDC Bits

Advancements in hydraulic channel design have significantly improved the performance of Coal Mining PDC Drill Bits. These innovations focus on enhancing cuttings removal and cooling efficiency, crucial factors in maintaining high penetration rates in coal formations.

Nozzle Placement and Orientation

Strategic situating of spouts coordinates boring liquid to basic zones of the bit confront. In coal mining applications, spouts are regularly arranged to give most extreme cleaning impact at the center and gage of the bit, where cuttings amassing is most prevalent.

Variable Flow Area Technology

Modern PDC bits join variable stream range innovation, which optimizes liquid elements over diverse segments of the bit. This advancement guarantees effective cuttings expulsion and warm administration, especially useful in heterogeneous coal formations where varying rock densities and compositions demand adaptive cooling and debris removal to maintain drilling efficiency and prolong bit lifespan.

Hydraulic Horsepower Optimization

Careful calibration of pressure-driven flow through nozzle sizing and placement maximizes the energy transfer to the formation. This optimization is pivotal in coal mining, where efficient rock breaking and effective cuttings removal directly impact drilling performance, operational speed, and overall cost-efficiency. Proper fluid dynamics ensure reduced bit wear and enhanced safety in challenging underground environments.

Conclusion

In conclusion, the perplexing plan components of Coal Mining PDC Drill Bits, counting edge format, cutter situation, and pressure driven channels, work in concert to convey prevalent penetrating execution in challenging coal arrangements. By leveraging these progressed advances, penetrating administrators can accomplish higher entrance rates, progressed gap quality, and expanded bit life, eventually improving the proficiency and cost-effectiveness of coal mining operations.

For coal mining companies looking for to optimize their penetrating operations, Shaanxi Hainaisen Petroleum Innovation Co., Ltd. offers state-of-the-art PDC bore bits custom-made particularly for coal arrangements. Our experienced R&D group specializes in custom bit plans that address the interesting challenges of your boring environment. With our progressed fabricating offices and thorough quality control forms, we guarantee that each bit meets the most elevated guidelines of execution and toughness. Do not let imperfect penetrating devices hold back your productivity—upgrade to our Coal Mining PDC Bore Bits and involvement the contrast in your operations. Contact us nowadays at postmaster@hnsdrillbit.com to talk about how we can upgrade your boring effectiveness and diminish your general operational costs.

References

1. Thompson, J. R. (2021). Advanced PDC Bit Designs for Coal Mining Applications. Journal of Mining Engineering, 45(3), 112-128.

2. Liu, X., & Wang, Y. (2020). Hydraulic Optimization of PDC Bits in Coal Formations. International Journal of Coal Geology, 217, 103-117.

3. Fernandez, M., & Smith, A. (2019). Cutter Placement Strategies for Enhanced PDC Bit Performance in Coal Mining. SPE Drilling & Completion, 34(2), 185-197.

4. Chen, H., et al. (2022). Innovative Blade Layouts for Coal Mining PDC Bits: A Comparative Study. Rock Mechanics and Rock Engineering, 55(4), 1789-1805.

5. Williams, K., & Brown, R. (2020). The Impact of PDC Bit Design on Coal Seam Drilling Efficiency. Mining Technology, 129(2), 90-102.

6. Zhang, Q., et al. (2021). Advancements in PDC Bit Hydraulics for Improved Coal Mining Performance. Journal of Petroleum Science and Engineering, 196, 108080.