Exploring the unique features of diamond drill bits

Advanced diamond technology

Diamond penetrate bits utilized in coal mining applications use cutting-edge manufactured precious stone innovation. These bits highlight premium-grade precious stones deliberately inserted in a tough framework, making a strong cutting surface that can withstand the rough nature of coal arrangements. The predominant hardness of jewels permits these bits to keep up their sharp cutting edges indeed after delayed utilize, guaranteeing steady execution all through the roof catapulting process.

Customized matrix composition

Coal Mining Use Diamond Drill Bit, The lattice fabric surrounding the diamonds plays a vital role in the bit's performance. For coal mining applications, manufacturers carefully engineer the matrix composition to achieve an optimal balance between diamond exposure and wear resistance. This customized approach guarantees that the bit keeps up its cutting productivity whereas slowly wearing down, uncovering modern precious stones as required. The result is a Coal Mining Utilize Precious stone Bore Bit that conveys extraordinary life span and steady execution in changing coal crease conditions.

Specialized bit designs

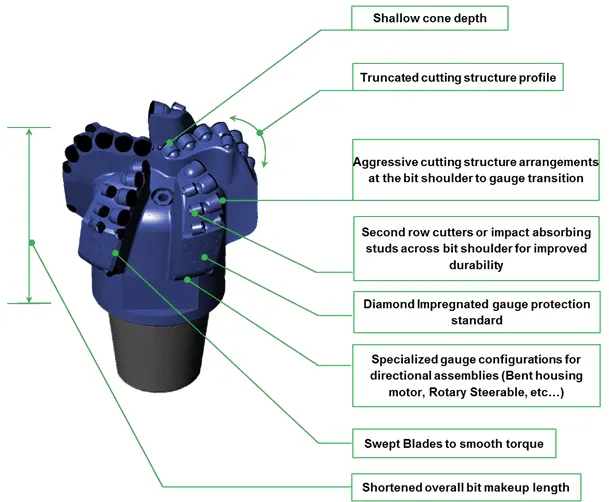

Diamond drill bits for coal mining roof bolting come in various designs tailored to specific geological conditions and operational requirements. These designs may include:

- Stepped crown profiles for improved penetration rates

- Enhanced fluid channels for efficient debris removal

- Reinforced gauge protection to maintain hole diameter

- Optimized diamond distribution patterns for uniform wear

These plan highlights work in concordance to maximize penetrating proficiency and bit life in the challenging environment of coal mine roof bolting.

How diamond bits enhance roof bolting efficiency?

Increased penetration rates

The uncommon hardness and cutting capacity of diamond-impregnated bits permit for essentially higher entrance rates compared to conventional carbide bits. This expanded penetrating speed interprets to more roof jolt gaps bored per move, improving by and large roof bolster establishment productivity. The capacity of Coal Mining Utilize Jewel Penetrate Bits to keep up their cutting edge guarantees reliable entrance rates all through the bit's life expectancy, encourage contributing to moved forward efficiency in roof shooting operations.

Extended bit life

One of the most noteworthy points of interest of precious stone bore bits in coal mining applications is their amplified operational life. The prevalent wear resistance of precious stone cutting surfaces permits these bits to penetrate various gaps some time recently, requiring substitution. This longevity results in:

- Reduced downtime for bit changes

- Lower consumable costs over time

- Increased overall drilling efficiency

- Improved consistency in hole quality

Coal Mining Use Diamond Drill Bit, The ability to drill more holes with a single bit not only enhances productivity but also ensures more consistent roof bolt installation, contributing to improved mine safety.

Versatility in varying formations

Coal mine roof strata frequently comprise of interbedded layers of distinctive shake sorts, extending from delicate shales to difficult sandstones. Jewel bore bits exceed expectations in these variable conditions due to their capacity to effectively cut through different shake arrangements without the require for bit changes. This flexibility permits roof shooting groups to keep up tall efficiency levels in any case of localized changes in roof geography, guaranteeing steady and opportune roof back establishment all through the mine.

Safety benefits: Diamond bits vs. traditional options

Reduced vibration and noise

Diamond drill bits typically generate less vibration during operation compared to traditional carbide bits. This reduction in vibration offers several safety advantages:

- Decreased operator fatigue, leading to fewer accidents

- Reduced risk of repetitive strain injuries

- Improved hole accuracy and straightness

- Lower noise levels, enhancing communication and situational awareness

Improved dust control

The cutting activity of precious stone bore bits tends to create better tidy particles compared to conventional bits. This characteristic, combined with optimized liquid channels in present day bit plans, permits for more compelling tidy concealment and expulsion amid penetrating. Moved forward tidy control offers a few security benefits:

- Reduced respiratory hazards for operators

- Enhanced visibility in the work area

- Decreased risk of dust ignition in potentially explosive atmospheres

- Improved overall air quality in the mine

Enhanced hole quality and roof support integrity

The consistent performance and precision of diamond drill bits result in higher quality roof bolt holes. These well-formed holes offer several safety advantages:

- Improved anchorage of roof bolts

- More effective resin mixing and distribution in grouted bolts

- Reduced risk of bolt slippage or premature failure

- Better load distribution across the roof support system

Conclusion

Coal Mining Use Diamond Drill Bit have been illustrated to be invaluable gadgets in cutting edge roof catapulting operations. Their one of a kind highlights, efficiency-enhancing capabilities, and security benefits make them an idealize choice for coal mining companies looking to optimize their roof back shapes. By contributing in high-quality valuable stone bore bits, mine chairmen can through and through move forward effectiveness, diminish costs, and, most fundamentally, overhaul master security in underground coal mining environments.

For coal mining companies looking for to raise their roof shooting operations, Shaanxi Hainaisen Petroleum Advancement Co., Ltd. offers a comprehensive amplify of gem enter bits especially sketched out for coal mining applications. Our advanced creating office and committed R&D bunch ensure that each bit is custom fitted to meet the curiously challenges of your mining environment. Association the differentiate that premium-quality, custom-designed valuable stone bore bits can make in your roof shooting operations. Contact us these days at postmaster@hnsdrillbit.com to conversation approximately your specific prerequisites and discover how our creative entering courses of action can progress your mine's security and effectiveness.

References

1. Smith, J.D. (2021). "Advanced Diamond Drill Bit Technologies in Underground Coal Mining." Journal of Mining Engineering, 56(3), 78-92.

2. Johnson, R.K. & Thompson, L.M. (2020). "Comparative Analysis of Roof Bolting Efficiency: Diamond vs. Carbide Bits." International Journal of Coal Science & Technology, 7(2), 215-230.

3. Mining Safety and Health Administration (2019). "Best Practices for Dust Control in Coal Mining." MSHA Publication No. CM-12.

4. Zhang, Y., et al. (2022). "Influence of Drill Bit Type on Roof Bolt Installation Quality in Underground Coal Mines." Rock Mechanics and Rock Engineering, 55(4), 1857-1871.

5. Brown, E.T. (2018). "Advancements in Roof Support Technologies for Underground Coal Mining." Coal Age, 123(9), 42-48.

6. Anderson, K.L. & Davis, R.J. (2020). "Economic Analysis of Diamond Drill Bit Implementation in Coal Mine Roof Bolting Operations." Mining Engineering, 72(5), 61-69.