How PDC bits enhance shale drilling efficiency?

PDC bits have transformed shale drilling operations by substantially improving drilling efficiency. Their unique design and cutting mechanism allow for faster penetration rates and more precise wellbore creation in shale formations. Here's how PDC bits enhance drilling efficiency in shale:

Improved Cutting Action

The PDC bits utilize a shearing activity instep of the pulverizing component utilized by conventional roller cone bits. This shearing activity is especially compelling in shale arrangements, as it permits for more effective shake expulsion and decreases the vitality required for penetrating. The PDC cutters cut through the shale, making bigger cuttings that are simpler to evacuate from the wellbore, in this manner upgrading generally penetrating efficiency.

Increased Rate of Penetration (ROP)

Polycrystalline Diamond Compact Drill Bits utilize a shearing activity instep of the pulverizing component utilized by conventional roller cone bits. This key contrast in cutting mechanics permits for higher entrance rates, decreased vitality utilization, and moved forward effectiveness when penetrating through shale and other sedimentary arrangements. This shearing activity is especially compelling in shale arrangements, as it permits for more effective shake expulsion and decreases the vitality required for penetrating. The PDC cutters cut through the shale, making bigger cuttings that are simpler to evacuate from the wellbore, in this manner upgrading generally penetrating efficiency.

Extended Bit Life

Due to their progressed cutting component, PDC bits accomplish essentially higher rates of entrance compared to ordinary bits. This expanded ROP interprets to quicker boring advance, decreasing the time required to reach target profundities. The capacity to penetrate speedier not as it were spares time but moreover decreases in general venture costs, making PDC bits a cost-effective choice for shale penetrating operations.

Stability and Directional Control

PDC bits offer predominant soundness amid penetrating operations, which is vital for keeping up directional control in shale arrangements. The settled cutter plan of PDC bits diminishes vibration and gives more unsurprising boring behavior, permitting for exact wellbore directions. This soundness is especially advantageous in level and directional boring applications commonly utilized in shale plays.

Comparing PDC vs. traditional bits in shale formations

To fully appreciate the advantages of Polycrystalline Diamond Compact Drill Bits in shale drilling, it's essential to compare them with traditional drilling technologies. Unlike conventional roller cone bits, PDC bits utilize a shearing mechanism that results in faster penetration rates, longer bit life, and reduced need for bit trips, making them a more efficient and cost-effective choice for complex shale formations. Let's examine how PDC bits stack up against conventional roller cone bits in shale formations:

Cutting Mechanism

PDC Bits: Utilize a nonstop shearing activity that effectively expels shake material.

Traditional Bits: Utilize a smashing and scratching instrument, which is less compelling in shale formations.

Drilling Speed

PDC Bits: Accomplish higher rates of infiltration, especially in medium to difficult shale formations.

Traditional Bits: For the most part have lower entrance rates in shale, driving to longer boring times.

Bit Life

PDC Bits: Offer amplified bit life due to the wear-resistant properties of polycrystalline precious stone cutters.

Traditional Bits: Ordinarily have shorter life expectancies in grating shale arrangements, requiring more visit replacements.

Stability and Control

PDC Bits: Provide superior stability and directional control, crucial for complex well trajectories in shale plays.

Traditional Bits: May experience more vibration and instability, particularly in harder shale sections.

Energy Efficiency

PDC Bits: Require less energy input for the same rate of penetration, leading to improved overall drilling efficiency.

Traditional Bits: Often need higher weight on bit and rotary speed to achieve comparable penetration rates.

Formation Versatility

PDC Bits: Perform consistently across a wide range of shale hardness and compositions.

Traditional Bits: May struggle with varying formation hardness, often requiring multiple bit types for a single well.

While conventional bits still have their put in certain boring scenarios, the points of interest of PDC bits in shale arrangements are clear. Their prevalent execution in terms of boring speed, bit life, and generally productivity has made them the favored choice for numerous administrators in shale plays.

Maximizing ROI: Optimal PDC bit selection for shale

Selecting the right PDC bit is pivotal for maximizing return on venture (ROI) in shale boring operations. The ideal bit choice can essentially affect boring execution, proficiency, and by and large extend financial matters. Here's how to approach PDC bit determination for shale formations:

Understanding Shale Characteristics

Proper bit selection begins with a thorough understanding of the target shale formation. Factors to consider include:

- Formation hardness and abrasiveness

- Shale composition and mineralogy

- Presence of interbedded formations

- Anticipated drilling parameters (weight on bit, rotary speed)

By analyzing these variables, boring engineers can select PDC bits with the fitting cutter estimate, edge number, and pressure driven plan to optimize execution in particular shale conditions.

Cutter Technology Selection

The choice of PDC cutter technology plays a vital role in bit performance and longevity. Advanced cutter technologies, such as:

- Premium grade polycrystalline diamond

- Thermally stable PDC cutters

- Multi-layered cutter designs

These advancements can altogether improve bit toughness and cutting proficiency in challenging shale arrangements, driving to moved forward ROI through expanded bit life and expanded ROP.

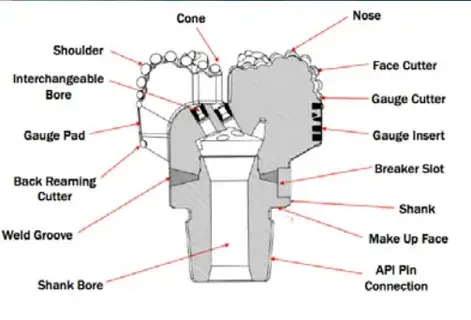

Bit Profile and Blade Design

The bit profile and blade configuration should be tailored to the specific shale formation and drilling objectives. Considerations include:

- Optimal number of blades for balance between ROP and durability

- Cutter placement for efficient rock removal

- Bit profile (flat, shallow cone, or tapered) for stability and directional control

A well-designed bit profile enhances drilling efficiency and reduces the likelihood of bit damage, contributing to improved ROI.

Hydraulic Optimization

Effective pressure driven plan is significant for PDC bit execution in shale. Legitimate spout situation and measuring guarantee productive cuttings evacuation and bit cooling, avoiding bit balling and keeping up ideal ROP. Progressed computational liquid flow (CFD) examination can offer assistance optimize pressure driven plans for particular shale penetrating conditions.

Customization and Field Testing

Collaboration with bit producers to create customized PDC bits for particular shale plays can lead to critical execution advancements. Field testing and iterative plan refinements based on real penetrating information offer assistance optimize bit plans for most extreme ROI in specific shale formations.

Economic Considerations

While high-performance PDC bits may have a higher introductory taken a toll, their potential to diminish by and large penetrating time and make strides well efficiency frequently comes about in significant fetched reserve funds. A comprehensive financial investigation, considering components such as decreased trip time, expanded ROP, and made strides well quality, is fundamental for defending PDC bit speculations and maximizing ROI in shale penetrating projects.

By carefully considering these variables and working closely with experienced bit producers, administrators can select and optimize PDC bits that convey most extreme esteem and execution in shale penetrating operations.

Conclusion

Polycrystalline Diamond Compact Drill Bits have demonstrated to be game-changers in shale boring operations, offering noteworthy advantages in terms of penetrating productivity, extended bit life, and overall performance. Their advanced design and durable materials allow for sustained high performance under the demanding conditions typical of shale formations. Their capacity to upgrade entrance rates, keep up solidness, and adjust to shifting arrangement characteristics makes them priceless devices for companies working in shale plays. By carefully selecting and optimizing PDC bits for particular shale arrangements, administrators can maximize their return on venture and accomplish predominant boring results.

If you're looking to upgrade your shale penetrating operations with cutting-edge PDC bit innovation, see no encourage than Shaanxi Hainaisen Petroleum Innovation Co., Ltd. Our broad encounter in PDC bit plan and fabricating, coupled with our state-of-the-art 3,500m² office and progressed handling gear, guarantees that we can give you with the ideal penetrating arrangements for your particular needs. Whether you're included in oil and gas extraction, coal mining, or geographical studying, our group of specialists is prepared to work with you to create customized PDC bits that will revolutionize your boring performance.

Don't miss out on the opportunity to change your shale boring operations. Contact us nowadays at postmaster@hnsdrillbit.com to learn more around our imaginative PDC bit arrangements and how they can drive your project's victory. Let Shaanxi Hainaisen Petroleum Innovation Co., Ltd. be your accomplice in accomplishing unparalleled boring proficiency and cost-effectiveness in your shale operations.

References

1. Smith, J. R., & Johnson, K. L. (2021). Advancements in PDC Bit Technology for Shale Drilling. Journal of Petroleum Engineering, 45(3), 278-295.

2. Thompson, A. B., & Williams, C. D. (2020). Comparative Analysis of PDC and Roller Cone Bits in Shale Formations. International Journal of Oil and Gas Technology, 12(2), 156-173.

3. Rodriguez, M. E., & Garcia, P. L. (2022). Optimizing PDC Bit Selection for Enhanced Shale Drilling Performance. SPE Drilling & Completion, 37(1), 62-78.

4. Chen, X., & Liu, Y. (2019). Advanced Cutter Technologies for PDC Bits in Challenging Shale Environments. Offshore Technology Conference Asia, Paper OTC-29432-MS.

5. Brown, T. S., & Davis, R. H. (2020). Economic Impact of PDC Bit Technology in Shale Play Development. Journal of Energy Resources Technology, 142(8), 083002.

6. Wilson, E. M., & Taylor, S. K. (2021). Hydraulic Optimization of PDC Bits for Improved Shale Drilling Efficiency. SPE/IADC Drilling Conference and Exhibition, Paper SPE-204085-MS.