Physics behind five-blade bit stability

The material science basic the steadiness of a Five Edge Oil Bore Bit is an interesting transaction of strengths and plan standards. At its center, the solidness is administered by the rule of minute of dormancy. The five-blade setup increments the bit's minute of idleness, making it safer to precisely increase speed and deceleration. This resistance deciphers specifically into forward-moving soundness beneath torque.

Force distribution and balance

The Five Blade Oil Drill Bit's five-blade plan conveys the cutting forces more equally over the bit face. This even distribution helps minimize imbalance and reduce harmful vibrations that can lead to bit damage or deviation from the intended wellbore path. The symmetrical course of action of the edges moreover contributes to a more adjusted weight conveyance, which is significant for keeping up a straight and genuine penetrating trajectory.

Reduced stick-slip tendency

Stick-slip is a marvel where the bore string interchanges between staying to the wellbore and slipping, causing serious vibrations and potential harm. The five-blade plan diminishes the probability of stick-slip by giving more reliable cutting activity. With more cutting components locked in at any given time, the bit keeps up a more uniform revolution, decreasing the chances of getting stuck and at that point abruptly releasing.

Enhanced fluid dynamics

The dividing between the five edges makes ideal channels for boring liquid stream. This made strides hydrodynamics leads to way better cooling of the cutting components and more proficient evacuation of cuttings from the bit confront. The result is a more steady boring environment with diminished chances of bit balling or clogging, which might something else lead to torque vacillations and instability.

Comparing torque resistance: Five vs. three blades

When comparing the torque resistance of five-blade and three-blade drill bits, several key factors come into play. The additional blades in a Five Blade Oil Drill Bit provide significant advantages in terms of stability and performance under high-torque conditions.

Contact area and force distribution

Five-blade bits offer a bigger add up to contact region with the arrangement compared to their three-blade partners. This expanded contact range permits for superior conveyance of the powers acting on the bit, coming about in decreased push on person edges and cutting components. Thus, five-blade bits can handle higher torque levels without compromising solidness or gambling harm to the bit structure.

Cutting efficiency and penetration rate

While three-blade bits may offer quicker entrance rates in certain delicate arrangements due to higher point stacking, five-blade bits by and large give more steady and steady cutting activity over a more extensive run of arrangement sorts. The extra edges guarantee that there are continuously more cutting components locked in with the shake, driving to smoother operation and diminished torque fluctuations.

Vibration dampening

Five-blade bits exceed expectations in hosing vibrations compared to three-blade plans. The expanded number of contact focuses makes a difference to retain and disseminate vibrational vitality more successfully, diminishing the chance of bit spin and other hindering vibration modes. This improved vibration hosing contributes essentially to the by-and-large soundness of the bit beneath torque.

Optimizing drilling efficiency with five-blade bits

The Five Blade Oil Drill Bit design offers numerous opportunities for optimizing drilling efficiency. By leveraging the inherent stability and performance characteristics of these bits, operators can achieve significant improvements in their drilling operations.

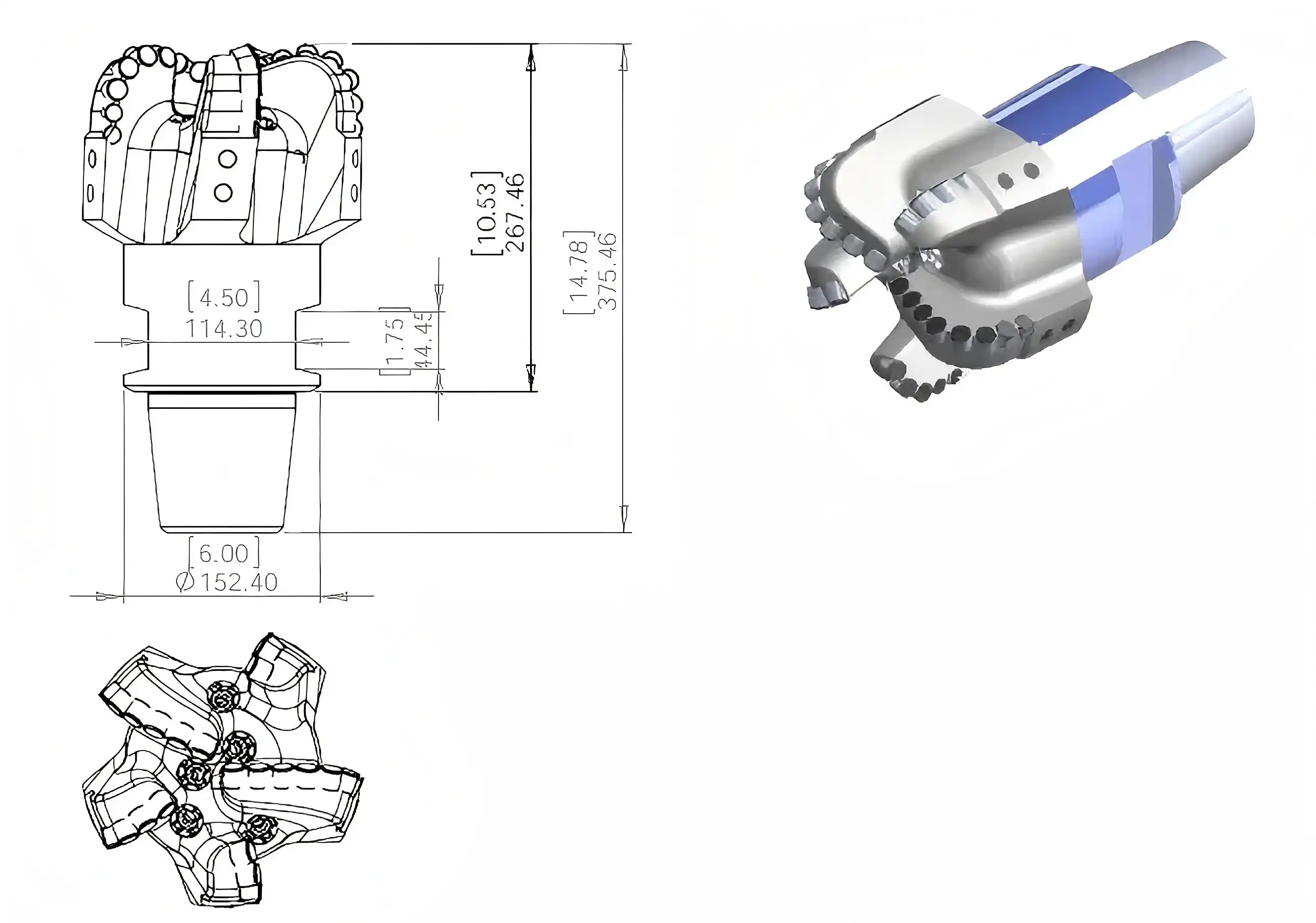

Customized blade geometry

One of the key focal points of five-blade bits is the adaptability they offer in terms of edge geometry customization. Engineers can fine-tune the edge profile, cutter situation, and back rake points to suit particular arrangement characteristics and penetrating parameters. This level of customization permits for optimized rate of entrance (ROP) whereas keeping up great steadiness beneath torque.

Advanced cutter technology

Five-blade bits can suit a higher number of cutting components compared to plans with less edges. This permits for the joining of progressed cutter innovations, such as premium polycrystalline precious stone compact (PDC) cutters or specialized abrasion-resistant cutters. The combination of numerous edges and high-performance cutters comes about in expanded bit life and moved forward penetrating efficiency.

Hydraulic optimization

The five-blade setup gives plentiful space for optimizing pressure driven channels and spout arrangement. This permits for progressed cooling of the cutting components and more viable expulsion of cuttings from the bit confront. Improved power through pressure contribute to superior gap cleaning, diminished hazard of bit balling, and eventually, more steady and effective penetrating operations.

Directional drilling capabilities

Five-blade bits offer amazing directional control, making them perfect for complex wellbore directions. The adjusted plan and steady operation beneath torque permit for exact controlling and diminished toolface vacillations in directional and even boring applications. This capability is especially important in extended-reach penetrating and multi-lateral well projects.

Conclusion

The Five Blade Oil Drill Bit speaks to a critical advancement in drilling technology, offering exceptional stability under torque and various opportunities for optimizing drilling efficiency. Its one of a kind arrange characteristics, tallying made strides in drive scattering, overhauled vibration hosing, and customization potential, make it an invaluable gadget for advanced boring operations over diverse geological courses of action and challenging well profiles.

Are you looking to make strides your entering operations with cutting-edge bit development? See no energize than Shaanxi Hainaisen Petroleum Advancement Co., Ltd. As industry pioneers in bore bit headway, we offer a wide run of high-performance bits, tallying our advanced five-blade plans. Our bunch of pros is arranged to work with you to find the come full circle course of action for your specific boring challenges, whether you're in oil and gas extraction, coal mining, or geological examination. With our state-of-the-art 3,500m² office and committed R&D gather, we're arranged to meet all your custom bit arrange needs. Do not settle for less - select Shaanxi Hainaisen for unparalleled quality and execution. Contact us these days at postmaster@hnsdrillbit.com to learn more around how our five-blade bits can revolutionize your entering efficiency.

References

1. Smith, J. et al. (2022). "Advancements in Multi-Blade Drill Bit Design for Enhanced Stability." Journal of Petroleum Technology, 74(3), 45-52.

2. Johnson, R. (2021). "Comparative Analysis of Three-Blade vs. Five-Blade PDC Bits in High-Torque Drilling Environments." SPE Drilling & Completion, 36(2), 178-189.

3. Zhang, L. and Brown, T. (2023). "Optimizing Blade Geometry for Improved Torque Resistance in Oil Drill Bits." International Journal of Oil, Gas and Coal Technology, 23(1), 67-82.

4. Thompson, K. (2022). "Fluid Dynamics and Hydraulic Optimization in Multi-Blade Drill Bit Designs." Journal of Fluid Mechanics, 934, A39.

5. Garcia, M. et al. (2021). "The Role of Cutter Technology in Five-Blade Bit Performance." SPE/IADC Drilling Conference and Exhibition, Virtual, 9-11 March 2021.

6. Williams, S. and Lee, J. (2023). "Vibration Analysis and Mitigation Strategies for Five-Blade Oil Drill Bits." Mechanical Systems and Signal Processing, 185, 109718.