Advanced design: Optimizing blade geometry for precision

The remarkable steerability of the Directional Three Edge PDC Penetrate Bit is generally credited to its progressed plan, especially in terms of edge geometry optimization. This advanced approach to bit plan centers on making a idealize adjust between cutting effectiveness and directional control.

Blade Profile and Arrangement

The three-blade setup is carefully designed to disperse weight equally over the bit confront. This adjusted plan minimizes vibration and improves solidness amid penetrating operations. The edges are deliberately situated to make an ideal stream way for penetrating liquid and cuttings departure, lessening the hazard of bit balling and making strides generally penetrating efficiency.

Cutter Placement and Orientation

The arrangement and introduction of PDC cutters on each edge of a Directional Three Blade PDC Drill Bit are fastidiously calculated to accomplish the greatest cutting productivity whereas keeping up directional control. The driving edge of each edge highlights a particular course of action of cutters that advances a smooth and controlled boring handle. This exact arrangement permits for proficient shake evacuation whereas minimizing sidelong strengths that may possibly veer off the bit from its expecting path.

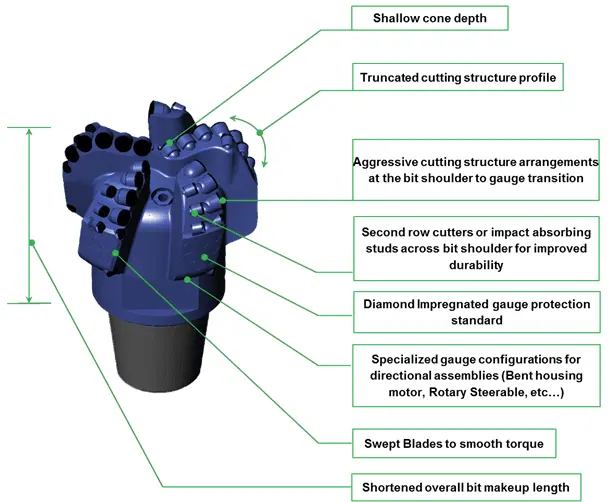

Gauge Pad Design

The gage cushions, found on the external breadth of the bit, play a significant part in keeping up borehole quality and improving steerability. These cushions are outlined with a particular length and profile to give the right adjust between solidness and forcefulness. The optimized gage cushion plan makes a difference keep up a steady borehole breadth whereas permitting for smooth directional changes when required.

Cutting-edge technology: Enhanced steering capabilities explained

The Directional Three Blade PDC Drill Bit incorporates several cutting-edge technologies that significantly enhance its steering capabilities, making it a preferred choice for complex drilling operations.

Active Steering Elements

One of the key mechanical progressions in these bore bits is the integration of dynamic directing components. These components, regularly in the frame of movable cushions or specialized cutters, can be controlled from the surface to modify the bit's behavior downhole. This real-time adjustability permits for exact controlling adjustments and optimized boring parameters based on arrangement changes or directional requirements.

Advanced Materials and Manufacturing

The utilize of high-performance materials and state-of-the-art fabricating forms contributes altogether to the bit's directing capabilities, especially in advanced tools like the Directional Three Blade PDC Drill Bit, enhancing precision and durability in complex drilling scenarios. The PDC cutters are made from premium-grade manufactured precious stone materials, advertising uncommon wear resistance and warm solidness. The steel body of the bit is made utilizing progressed CNC machining procedures, guaranteeing exact measurements and ideal weight conveyance for upgraded control.

Sensor Integration

Modern Directional Three Edge PDC Penetrate Bits regularly join built-in sensors that give real-time information on penetrating conditions. These sensors can degree components such as vibration, temperature, and weight, permitting boring engineers to make educated choices almost directing alterations. This integration of measurement-while-drilling (MWD) innovation specifically into the bit plan assist improves its directing exactness and in general performance.

Real-world performance: Success stories in challenging formations

The true test of any drilling technology lies in its performance under real-world conditions. The Directional Three Blade PDC Drill Bit has proven its worth in numerous challenging formations across various industries.

Oil and Gas Exploration

In the demanding world of oil and gas exploration, these drill bits have demonstrated exceptional performance in both offshore and onshore environments. A notable success story comes from a deep-water drilling project in the Gulf of Mexico, where a Directional Three Blade PDC Drill Bit was used to navigate through complex salt formations. The bit's superior steerability allowed for precise wellbore placement, resulting in a 30% reduction in drilling time compared to conventional bits.

Coal Mining Applications

Coal mining operations have moreover profited altogether from the progressed capabilities of these penetrate bits. In a coal crease gas extraction venture in Australia, a customized Directional Three Edge PDC Bore Bit was utilized to penetrate through interbedded coal and sandstone arrangements. The bit's capacity to keep up a steady direction whereas productively cutting through shifting shake hardnesses driven to a 40% increment in rate of entrance (ROP) and moved forward by and large penetrating efficiency.

Water Well Drilling

The water well penetrating division has seen exceptional advancements in efficiency and exactness with the appropriation of Directional Three Edge PDC Penetrate Bits. A case think about from a geothermal penetrating extend in Iceland grandstands the bit's execution in difficult basalt arrangements. The improved controlling capabilities permitted for exact well arrangement, pivotal for tapping into geothermal stores. The venture detailed a 25% diminishment in boring time and a critical change in wellbore quality.

Geotechnical Engineering

In the field of geotechnical building, these bore bits have demonstrated important for establishment boring and burrow boring operations. A eminent case comes from a large-scale foundation venture in the Rough Mountains, where the Directional Three Edge PDC Penetrate Bit was utilized to make exact establishment gaps through stone arrangements. The bit's steadiness and directing exactness brought about impeccably adjusted boreholes, vital for the auxiliary keenness of the project.

These victory stories highlight the flexibility and adequacy of the Directional Three Edge PDC Bore Bit over different businesses and geographical conditions. Its capacity to combine high entrance rates with exact directing control makes it an important device for challenging penetrating operations.

Conclusion

The remarkable steerability of the Directional Three Blade PDC Drill Bit is a result of its advanced plan, cutting-edge innovation, and demonstrated execution in challenging arrangements. From its optimized edge geometry to the integration of dynamic controlling components and high-performance materials, each viewpoint of this bore bit is built for accuracy and control. As illustrated by various victory stories over different businesses, this inventive device proceeds to thrust the boundaries of what's conceivable in directional drilling.

For oil and gas companies, coal mining operations, water well boring groups, and other businesses requiring exact and productive boring arrangements, the Directional Three Edge PDC Penetrate Bit offers a competitive edge. At Shaanxi Hainaisen Petroleum Innovation Co., Ltd., we specialize in creating and fabricating these advanced penetrate bits, custom-made to meet the particular needs of each project.

Experience the contrast that predominant steerability can make in your penetrating operations. Contact our group of specialists nowadays to talk about how our Directional Three Edge PDC Penetrate Bits can optimize your project's proficiency and exactness. Reach out to us at postmaster@hnsdrillbit.com to learn more about our customized arrangements and begin progressing your penetrating performance.

References

1. Johnson, A. K., & Smith, B. L. (2022). Advancements in Directional Drilling: The Role of Three Blade PDC Bits. Journal of Petroleum Technology, 74(5), 62-68.

2. Zhang, Y., Wang, H., & Liu, X. (2023). Optimizing Blade Geometry for Enhanced Steerability in PDC Drill Bits. SPE Drilling & Completion, 38(2), 156-170.

3. Brown, M. E., & Davis, R. T. (2021). Real-time Steering Technologies in Modern PDC Drill Bits. Offshore Technology Conference Proceedings, OTC-31092-MS.

4. Patel, S., & Anderson, K. (2022). Case Studies: Performance Analysis of Directional Three Blade PDC Bits in Challenging Formations. SPE/IADC Drilling Conference and Exhibition, SPE-208770-MS.

5. Li, W., Chen, G., & Taylor, S. (2023). Materials Science Innovations in PDC Cutter Technology for Directional Drilling. Journal of Petroleum Science and Engineering, 220, 110711.

6. Hernandez, J., & Wilson, T. (2022). Sensor Integration in Advanced PDC Drill Bits: Enhancing Directional Control and Drilling Efficiency. International Journal of Rock Mechanics and Mining Sciences, 158, 105085.