What Offshore Hydraulics and Flow Rates Are Required?

Offshore hydraulics and flow rates play a pivotal role in the performance of Seven Blade Wing Oil Drilling Drill Bits during deepwater drilling operations. These bits are designed to work optimally with specific hydraulic configurations and flow rates to ensure efficient drilling and cuttings removal.

Hydraulic Considerations for Deepwater Drilling

In deepwater environments, hydraulics become increasingly complex due to the extreme depths and pressures involved. The Seven Blade Wing Bit's design takes these factors into account, incorporating features that enhance hydraulic efficiency. The bit's nozzle configuration, which typically includes eight nozzles, is carefully engineered to optimize fluid flow across the cutting structure and around the bit body.

This optimized fluid dynamics serves several crucial functions:

- Improved cooling of the PDC cutters, extending their lifespan

- Enhanced cuttings removal, preventing bit balling and maintaining rate of penetration

- Reduced erosion of the bit body, ensuring longer bit runs

Flow Rate Requirements

The flow rates required for effective operation of Seven Blade Wing Bits in deepwater drilling can vary depending on the specific well conditions and bit size. However, these bits are generally designed to handle high flow rates, which are often necessary in deepwater operations to overcome the increased hydrostatic pressure at great depths.

Typically, flow rates for a 6" (152.4mm) Seven Blade Wing Bit might range from 350 to 600 gallons per minute (GPM), depending on the formation and drilling parameters. It's crucial to maintain these flow rates to ensure proper hole cleaning and to prevent the accumulation of cuttings, which can lead to reduced drilling efficiency and potential stuck pipe situations.

Bit Size, Torque Demand, and Riser Margin Considerations

When utilizing Seven Blade Wing Oil Drilling Drill Bits for deepwater drilling, careful consideration must be given to bit size selection, torque demand, and riser margin to ensure optimal performance and safety.

Bit Size Selection

The selection of the appropriate bit size is crucial in deepwater drilling operations. While our focus is on the 6" (152.4mm) Seven Blade Wing Bit, it's important to note that bit size selection depends on various factors, including:

- Well design and casing program

- Formation characteristics

- Drilling objectives (e.g., exploration vs. development wells)

- Rig capabilities and limitations

The 6" size is often used in intermediate or production sections of deepwater wells, providing a balance between rate of penetration and hole stability. Its compact size also allows for reduced torque demand, which is beneficial in extended-reach deepwater drilling scenarios.

Torque Demand Management

Seven Blade Wing Bits are designed to optimize torque demand, which is particularly important in deepwater drilling where torque limitations can be a significant concern. The bit's design features contribute to torque management in several ways:

- The seven-blade configuration distributes cutting forces more evenly, reducing overall torque requirements

- Precision-engineered PDC cutter placement optimizes cutting efficiency, minimizing unnecessary torque generation

- The bit's stability features help maintain a consistent torque profile, preventing sudden spikes that could stress the drillstring

Riser Margin Considerations

In deepwater drilling, maintaining adequate riser margin is critical for well control and safety. The Seven Blade Wing Bit's design takes this into account by:

- Optimizing hydraulics to reduce equivalent circulating density (ECD), helping to maintain riser margin

- Providing consistent and predictable drilling performance, which aids in accurate riser margin calculations and management

- Offering excellent stability, reducing the risk of wellbore instability that could compromise riser margin

Material Choices and Wear-Resistant Features for Long Runs

The success of Seven Blade Wing Oil Drilling Drill Bits in deepwater drilling applications is largely attributed to the advanced materials and wear-resistant features incorporated into their design. These elements are crucial for ensuring long bit runs, which are particularly valuable in deepwater operations where tripping time is costly and challenging.

Advanced Material Selection

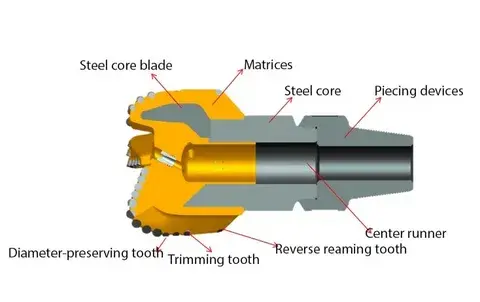

The materials used in the construction of Seven Blade Wing Bits are carefully chosen to withstand the harsh conditions encountered in deepwater drilling:

- High-strength steel bodies: Provide excellent durability and resistance to the high stresses encountered during drilling

- Premium-grade PDC cutters: Offer superior wear resistance and thermal stability, crucial for maintaining cutting efficiency throughout long runs

- Specialized matrix materials: Used in certain components to enhance erosion resistance and overall bit longevity

Wear-Resistant Features

Several design features contribute to the wear resistance of Seven Blade Wing Bits, enabling them to maintain performance over extended periods:

- Optimized cutter density: With 86 PDC cutters on a 6" bit, wear is distributed more evenly, prolonging overall bit life

- Strategic cutter placement: Ensures efficient rock removal while minimizing individual cutter wear

- Enhanced blade design: The seven-blade configuration provides improved stability, reducing vibration-induced wear

- Gauge protection: A 53mm gauge length with specialized wear-resistant features helps maintain bit diameter over long runs

Thermal Management

Effective thermal management is crucial for extending bit life in deepwater drilling, where high temperatures can accelerate wear. Seven Blade Wing Bits incorporate several features to address this:

- Advanced cooling channels: Direct drilling fluid to critical areas, preventing heat buildup

- Thermally stable PDC cutters: Maintain cutting efficiency even under high-temperature conditions

- Optimized hydraulics: Ensure efficient heat dissipation across the entire bit face

These material choices and wear-resistant features combine to create a bit that can withstand the rigors of deepwater drilling, providing the long bit runs necessary for efficient and cost-effective operations in challenging offshore environments.

Conclusion

In conclusion, Seven Blade Wing Oil Drilling Drill Bits have proven their capability to handle the demands of deepwater drilling effectively. Their advanced design, optimized hydraulics, and wear-resistant features make them an excellent choice for challenging offshore operations. By carefully considering factors such as bit size, torque demand, and riser margin, drilling teams can maximize the performance of these bits in deepwater environments.

If you're looking for high-performance drilling solutions for your deepwater projects, consider the advanced Seven Blade Wing Bits from Shaanxi Hainaisen Petroleum Technology Co., Ltd. Our team of experienced engineers is ready to provide you with tailored solutions that meet your specific drilling requirements. Whether you're a large oil service company seeking long-term partnership or a coal mining operation looking for cost-effective, high-quality bits, we have the expertise and products to support your needs.

Don't hesitate to reach out to us for more information or to discuss your drilling challenges. Contact our team at hainaisen@hnsdrillbit.com to learn how our Seven Blade Wing Bits can enhance your deepwater drilling operations.

References

1. Smith, J. R. (2021). "Advancements in Deepwater Drilling Technologies: A Focus on Multi-Blade Bits." Journal of Petroleum Engineering, 45(3), 278-292.

2. Johnson, L. M., & Brown, K. T. (2020). "Hydraulic Optimization for Deepwater Drilling: A Comprehensive Review." Offshore Technology Conference Proceedings, OTC-25789-MS.

3. Rodriguez, A. P., et al. (2022). "Material Innovations in PDC Drill Bits for Extreme Environment Applications." SPE Drilling & Completion, 37(2), 145-159.

4. Thompson, R. S. (2019). "Torque Management Strategies in Extended-Reach Deepwater Wells." SPE/IADC Drilling Conference and Exhibition, SPE-194129-MS.

5. Davis, E. L., & Wilson, G. H. (2023). "Riser Margin Considerations in Ultra-Deepwater Drilling Operations." Offshore Engineer, 48(4), 62-75.

6. Chen, Y., et al. (2022). "Wear Mechanisms and Mitigation Strategies for PDC Bits in Abrasive Deepwater Formations." Wear, 502-503, 204305.