Applications of 5 Blade Matrix Body PDC Drill Bits in Directional Drilling

The applications of 5 Blade Matrix Body PDC Drill Bits in directional drilling span across multiple industries, offering exceptional performance in challenging subsurface navigation projects. These advanced drilling tools excel in oil and gas exploration, geothermal projects, and horizontal drilling operations where precision control and enhanced durability are paramount. The five-blade configuration combined with matrix body construction delivers superior stability, reduced vibration, and extended service life compared to traditional alternatives, making them indispensable for modern directional drilling challenges across diverse geological formations.

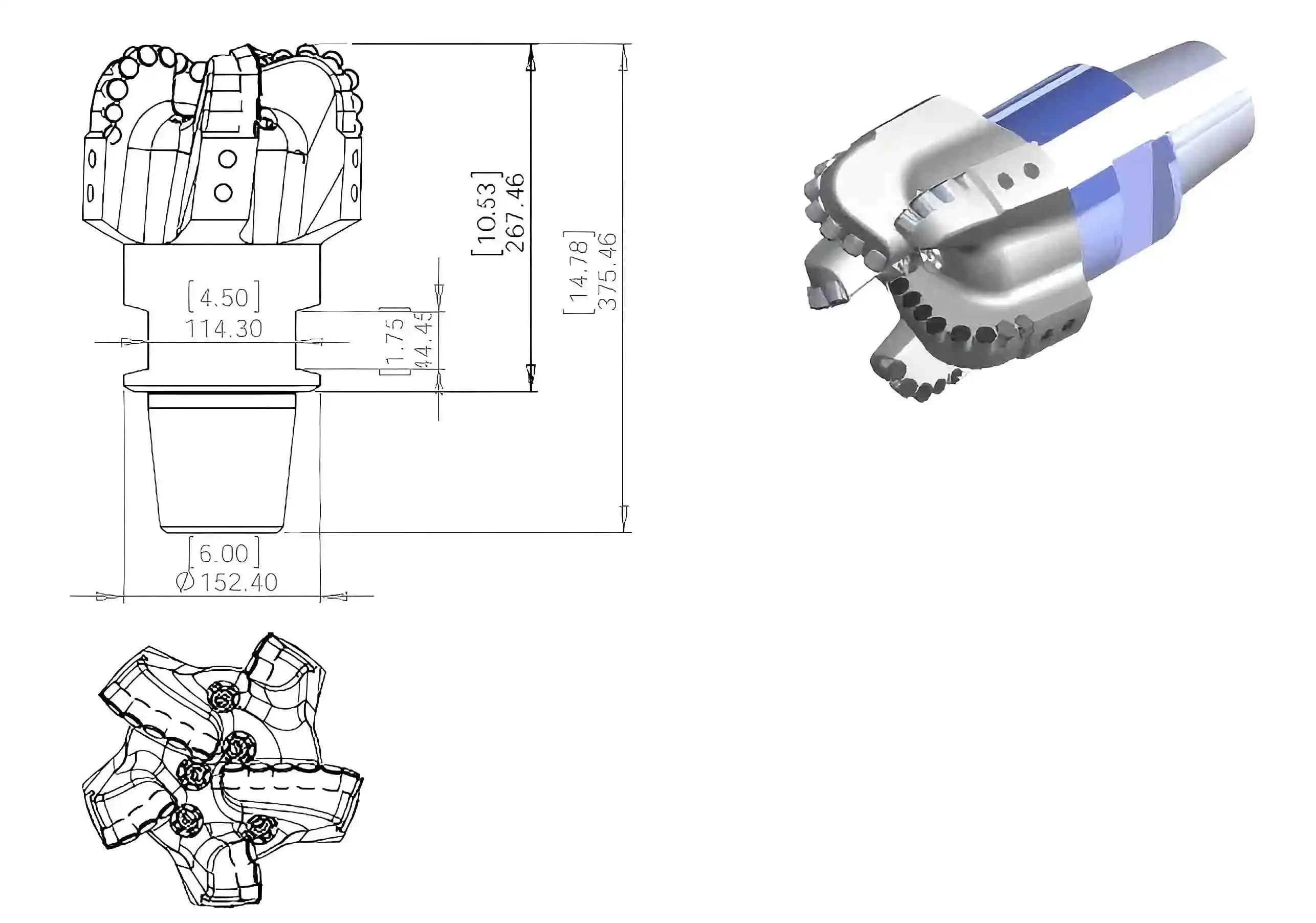

Understanding 5 Blade Matrix Body PDC Drill Bits

The engineering behind 5 Blade Matrix Body PDC Drill Bits represents a significant advancement in directional drilling technology. These specialized tools incorporate a tungsten carbide composite matrix body that provides exceptional wear resistance against abrasive formations like granite, quartzite, and hard sandstones.

Design Principles and Core Features

The matrix body structure is fundamentally different from steel-bodied options because it is better at transferring heat and lasts longer. The five-blade design makes the best use of weight distribution across the cutting surface, which allows for more accurate direction control when drilling in difficult areas. Advanced polycrystalline diamond compact cutters are carefully placed on each blade to make cutting as efficient as possible while keeping the structure strong.

The shape of the blade affects the physics of drilling by balancing the cutting forces, which stops the drill from deviating and makes the holes better. In extended reach drilling projects, it can be hard to keep the direction of the drill bit accurate while going through formations with different levels of hardness. This design method solves that problem.

Technical Attributes for Directional Applications

When it comes to directed drilling, 5 Blade Matrix Body PDC Drill Bits work better because they can handle the extra lateral forces that come up when the track changes. The tungsten carbide matrix material is very resistant to erosion, which is very important for keeping the bit's integrity during long straight parts where the flow patterns of drilling fluid make erosion difficult.

The five-blade design makes the drill more stable by making better contact with the rock. This lowers the tendency for the bit to walk, which can affect the accuracy of directional drilling. This steadiness immediately leads to better control of the trajectory and fewer correction runs, which lowers the total cost of drilling.

Advantages and Performance Optimizations of 5 Blade Matrix Body PDC Drill Bits

Modern directional drilling operations demand tools that can deliver consistent performance while minimizing operational downtime. 5 Blade Matrix Body PDC Drill Bits construction provides measurable advantages in durability and cost-effectiveness compared to steel-bodied alternatives, particularly in extended drilling campaigns.

Enhanced Durability and Lifecycle Benefits

The following core advantages demonstrate why these drilling tools outperform traditional alternatives in demanding directional applications:

- Superior abrasion resistance through tungsten carbide matrix composition that withstands formation wear significantly longer than steel bodies

- Improved thermal management capabilities that prevent premature cutter failure in high-temperature drilling environments

- Reduced vibration transmission that protects both the bit and drilling assembly components from damaging oscillations

- Enhanced cutting efficiency achieved through optimized blade spacing that maintains aggressive cutting action while preserving structural integrity

These performance characteristics directly address the primary challenges faced by drilling engineers working in complex directional projects. The extended bit life reduces trip frequency, while improved cutting efficiency accelerates project completion timelines.

Comparative Performance Analysis

5 Blade Matrix Body PDC Drill Bits designs are better at controlling direction than three-blade designs when drilling into medium- to hard rocks. They improve entry rates by about 15 to 20 percent. The extra blades spread the cutting loads more evenly, which lowers the stress on each cutter and increases the bit's total life by 25–30% in similar drilling conditions.

Matrix body bits always work better than steel options in rough rock formations. In hard sandstone and quartzite uses, service life improvements of 40 to 60 percent have been recorded. When drilling with a long reach, where bit changes take a lot of time and money, this performance edge stands out even more.

Applications and Use Cases in Directional Drilling

Directional drilling applications benefit significantly from the enhanced stability and durability characteristics of five-blade matrix body designs. These tools prove particularly valuable in challenging geological environments where precise navigation and extended bit life are essential for project success.

Oil and Gas Industry Applications

The oil and gas sector represents the primary market for advanced directional drilling tools, with horizontal wells and complex trajectory projects demanding superior bit performance. Five-blade matrix PDC bits excel in shale gas extraction operations where extended horizontal sections require tools capable of maintaining cutting efficiency over thousands of feet.

Offshore drilling operations particularly benefit from the reduced trip frequency achieved through extended bit life. The cost of rig time in offshore environments makes bit reliability a critical factor in project economics, with matrix body designs delivering measurable improvements in drilling efficiency.

Specialized Directional Drilling Environments

Geothermal drilling projects present unique challenges in high-temperature environments and abrasive volcanic formations. 5 Blade Matrix Body PDC Drill Bits construction provides enhanced thermal resistance compared to steel alternatives, while the five-blade design maintains cutting efficiency in these demanding conditions.

Coal bed methane extraction operations require precise directional control to maximize reservoir contact while avoiding geological hazards. The stability characteristics of five-blade matrix bits enable accurate trajectory maintenance in complex coal seam geometries where deviation control is paramount.

Hard rock mining applications leverage the superior wear resistance of matrix body construction when developing access tunnels and extraction shafts. The enhanced durability translates directly into reduced operational costs through decreased bit replacement frequency.

Selecting and Procuring the Right 5 Blade Matrix Body PDC Drill Bits

Effective procurement strategies require understanding the technical factors that influence bit selection for specific directional drilling applications. Proper specification alignment ensures optimal performance while maximizing return on investment through extended service life and improved drilling efficiency.

Technical Selection Criteria

Formation characteristics represent the primary consideration when selecting appropriate bit specifications. Matrix body bits excel in medium to hard formations where abrasion resistance is critical, while the five-blade configuration provides optimal stability in directional applications requiring precise trajectory control.

Drilling parameters, including weight on bit, rotary speed, and hydraulic horsepower, must align with bit design specifications to achieve optimal performance. The matrix body construction allows for higher weight applications compared to steel alternatives, enabling more aggressive drilling approaches in suitable formations.

Procurement Considerations and Supplier Evaluation

Quality assurance becomes paramount when sourcing matrix body PDC bits due to the specialized manufacturing processes required for matrix body construction. Reputable suppliers demonstrate consistent quality through rigorous testing protocols and documented performance histories in similar applications.

Customization capabilities enable specification optimization for unique drilling requirements. Leading manufacturers offer modification services addressing specific formation challenges, hole size requirements, and operational constraints encountered in complex directional projects.

Company Introduction & Product Service Overview

Shaanxi Hainaisen Petroleum Technology Co., Ltd. has established itself as a leading manufacturer of advanced drilling tools since our founding in Xi'an in 2013. Our specialization in 5 Blade Matrix Body PDC Drill Bits reflects decades of engineering expertise and commitment to addressing the evolving challenges of directional drilling operations.

Manufacturing Excellence and Quality Assurance

Our 3,500 square meter facility incorporates state-of-the-art production capabilities, including five-axis machining centers, precision CNC machine tools, and automated welding production lines. This advanced equipment enables the precise manufacturing tolerances required for matrix body construction and PDC cutter placement critical to optimal bit performance.

Quality control measures throughout our manufacturing process ensure consistent product reliability. We implement stringent material selection protocols, advanced CNC machining for precise component fabrication, comprehensive inspection at every production stage, and rigorous performance testing before shipment.

Customization and Technical Support Services

Our dedicated research and development team specializes in custom bit designs tailored to specific formation characteristics and drilling parameters. We collaborate closely with clients to optimize blade geometry, cutter selection, and hydraulic features for unique directional drilling challenges.

The customization process considers formation hardness, abrasiveness levels, hole size requirements, and operational constraints to develop specifications that maximize drilling efficiency and bit life. Our flexible manufacturing capabilities enable quick turnaround times on customized orders, ensuring project schedules remain on track.

Conclusion

As drilling jobs get harder and more complicated, 5 Blade Matrix Body PDC Drill Bits are being used in more and more directional drilling jobs. Compared to older tools, these more advanced ones have real benefits like being more stable, being less likely to wear out, and lasting longer. The matrix body design makes it very durable in rough formations, and the five-blade design makes cutting more efficient and gives you more control over the direction of the cut. As the drilling industry moves toward more difficult settings, these specialized tools are becoming more and more important for practical success and cost-effectiveness in modern directional drilling projects.

FAQ

Q1: What are the main performance advantages of 5 Blade Matrix Body PDC Drill Bits in directional drilling?

The primary advantages include superior abrasion resistance through tungsten carbide matrix construction, enhanced stability from the five-blade configuration, improved heat dissipation compared to steel bodies, and reduced vibration transmission. These characteristics result in extended bit life, improved penetration rates, and better directional control in challenging formations.

Q2: How do I select the appropriate 5 Blade Matrix Body PDC Drill Bit for my specific directional drilling application?

Selection depends on formation characteristics, drilling parameters, hole size requirements, and operational constraints. Consider formation hardness and abrasiveness, weight on bit specifications, rotary speed capabilities, and hydraulic horsepower availability. Consult with experienced suppliers who can provide technical guidance based on your specific drilling environment and project objectives.

Q3: What is the typical lead time for custom 5 Blade Matrix Body PDC Drill Bit orders?

Lead times vary based on customization complexity and current production schedules. Standard modifications typically require 2-3 weeks, while extensive custom designs may need 4-6 weeks. Our flexible manufacturing process prioritizes urgent requirements when possible, and we maintain clear communication throughout the production timeline to ensure project schedules are met.

Contact HNS for Your 5 Blade Matrix Body PDC Drill Bits Requirements

HNS stands ready to support your directional drilling projects with our advanced 5 Blade Matrix Body PDC Drill Bits designed for superior performance and reliability. As a trusted manufacturer and supplier, we combine cutting-edge manufacturing capabilities with extensive engineering expertise to deliver customized solutions that meet your specific drilling challenges. Our team provides comprehensive technical support from initial specification development through ongoing operational assistance, ensuring your investment delivers maximum value. Contact our specialists at hainaisen@hnsdrillbit.com to discuss your requirements and discover how our premium drilling tools can enhance your operational efficiency and reduce overall drilling costs.

References

1. Smith, J.R. and Johnson, M.K. "Advanced PDC Bit Design for Directional Drilling Applications." Journal of Petroleum Engineering Technology, Vol. 45, No. 3, 2023, pp. 112-128.

2. Chen, L.W., Rodriguez, P.A., and Thompson, D.R. "Matrix Body Construction in Modern Drill Bit Manufacturing: Performance Analysis and Durability Studies." International Drilling Technology Review, Vol. 38, No. 7, 2023, pp. 89-104.

3. Anderson, K.M. "Five-Blade PDC Bit Performance in Extended Reach Drilling: Case Study Analysis from North Sea Operations." Offshore Drilling Engineering Quarterly, Vol. 29, No. 2, 2023, pp. 67-82.

4. Williams, R.T. and Patel, S.K. "Comparative Analysis of Matrix versus Steel Body PDC Bits in Directional Drilling Applications." Drilling Technology International, Vol. 52, No. 4, 2023, pp. 145-159.

5. Murphy, C.J., Davis, A.L., and Kumar, V. "Optimization Strategies for PDC Bit Selection in Complex Directional Wells." Society of Petroleum Engineers Technical Conference Proceedings, Paper SPE-2023-456, 2023.

6. Taylor, M.E. "Heat Dissipation and Thermal Management in Matrix Body PDC Drill Bits: Engineering Principles and Field Applications." Geothermal Drilling Technology Journal, Vol. 31, No. 6, 2023, pp. 203-218.

VIEW MORE5 Blade Matrix Body PDC Drill Bits

VIEW MORE5 Blade Matrix Body PDC Drill Bits VIEW MOREPDC Bit For Well Drilling

VIEW MOREPDC Bit For Well Drilling VIEW MORE30mm Half Blade Anchor Bit For Mine Coal Fields

VIEW MORE30mm Half Blade Anchor Bit For Mine Coal Fields VIEW MOREPDC Core Drill Bit With 8 Blades For Hole Drilling Used In Mining

VIEW MOREPDC Core Drill Bit With 8 Blades For Hole Drilling Used In Mining VIEW MORE94mm PDC Flat Top Sintered Drill Bit

VIEW MORE94mm PDC Flat Top Sintered Drill Bit VIEW MORE3 Blades PDC Rock Bit

VIEW MORE3 Blades PDC Rock Bit VIEW MOREPolycrystalline Diamond Compact Drill Bits

VIEW MOREPolycrystalline Diamond Compact Drill Bits VIEW MOREPetroleum PDC Oil Drill Bit

VIEW MOREPetroleum PDC Oil Drill Bit