Latest Design Innovations in Diamond PDC Drill Bit Technology

The newest design improvements in Diamond PDC Drill Bit technology are huge steps forward in the drilling business and will change the way we work with difficult rock types. These cutting-edge polycrystalline diamond compact bits have advanced cutter shapes, better thermal stability features, and improved hydraulic designs that make drilling much more efficient. Modern improvements to Diamond PDC Drill Bits are aimed at making them last longer while also increasing their entry rates in a wide range of drilling situations, such as in mining and oil and gas research.

Understanding Diamond PDC Drill Bit Technology

Diamond PDC (Polycrystalline Diamond Compact) drill bits are a big step forward in drilling technology. They have ultra-hard diamond cutters and strong bit bodies that make them last longer and dig deeper. The main part of these high-tech tools is a steel bit body with fake diamond cutters carefully placed on it to make a cutting structure that works well.

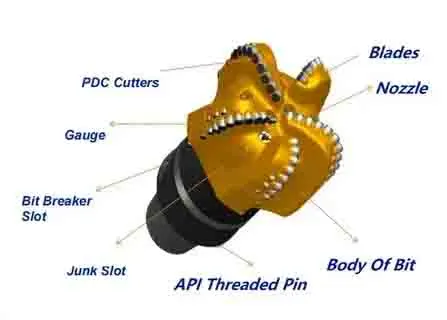

Fundamental Components and Design Principles

The main structure of the current Diamond PDC Drill Bits is made up of several important parts that work together to make the drilling process better. A high-quality steel alloy is usually used to make the bit body, which provides structural stability and houses the diamond cuts in well-planned places. Polycrystalline diamond technology is used in these diamond cutters. This is when manufactured diamond crystals are joined together under very high temperatures and pressures.

Adding a diamond to the cutter surfaces improves cutting efficiency by slicing the material instead of breaking it, as regular roller cone bits do. This shearing method produces less heat and sound, which makes drills go more smoothly and extends the life of the equipment. The diamond has an extremely high Mohs hardness value of 10, which means it will work well even in the roughest rock forms.

Advanced Manufacturing Techniques

Modern production techniques have changed the way these precise cutting tools are made. Precision diamond anchoring methods make sure that the cutter is placed correctly and that the bond is strong. Computer-aided design systems then make sure that the cutters are set up in the best way for the rock conditions. 5-axis machining centers and CNC machine tools are used in modern facilities to make standards that were not possible in the past.

At every step of the manufacturing process, from choosing the raw materials to testing the finished product, strict quality control measures are in place. Engineers can use advanced modeling software to guess how a bit will work in different drilling situations before the actual production starts. This cuts down on development time and makes sure that the quality of the results is always the same.

Comparing Advanced Drill Bit Technologies

When choosing the right drill bit technology, you need to carefully think about the qualities of the material, the needs of the job, and the cost. Bit design has changed a lot in the drilling business, with different technologies trying to be the best in different situations.

Diamond PDC vs. Tungsten Carbide Performance

When it comes to strength and wear resistance, Diamond PDC Drill Bits are much better than tungsten carbide options. While tungsten carbide bits work well in lighter rock, they have trouble staying sharp when cutting harder rock, which is where diamond cuts really shine. Polycrystalline diamond is much harder than other diamonds, so it can penetrate deeper and last much longer.

In tough cutting conditions, tungsten carbide bits usually need to be replaced more often, which means more downtime and higher running costs. Diamond PDC technology gets around these problems by keeping the cutting edge sharp during long drilling operations. This is especially helpful in deep well uses where changing bits is expensive and takes a lot of time.

Traditional vs. Modern Hybrid Technologies

The way that traditional roller cone bits work is through a crushing device that can work in some geological situations but makes a lot of noise and heat. These days, hybrid methods try to get the best of several technologies, but they often sacrifice speed for flexibility. Diamond PDC bits work the same way in different types of rock without having to make design changes.

In directional drilling, where exact control and regular performance are very important, diamond PDC technology really shows how useful it is. Traditional bits often have trouble keeping their paths straight, but PDC designs are easier to steer and control.

Performance Optimization and Durability Innovations

Diamond PDC Drill Bits can now do more than they could before because cutter shape, bonding materials, and heat protection are always getting better. Modern design methods focus on making drills as efficient as possible while also making sure that the equipment will last in harsh circumstances.

Advanced Cutter Geometry Designs

Recent changes in the shape of the cutter have completely changed how well it drills by improving chip removal and making cutting angles more efficient. Engineers now make cutter shapes that balance how well they cut with how long they last. This way, they can get the best results from rocks of different hardness levels. With these geometry changes, cutting forces are lowered while penetration rates stay high.

The newest cutting designs use advanced modeling methods that take into account how rocks interact, how bits rotate, and how hydraulic fluid flows. This all-around method makes drilling processes more efficient, using less energy and making bits last longer.

Enhanced Bonding Materials and Heat Resistance

Modern bonding technologies use complex metalworking methods to make the links between diamond cuts and bit bodies stronger. These better bonding materials can handle higher temperatures and stress levels, which means they can be used in deep digging and geothermal uses where regular bonding methods don't work.

Improvements to heat protection include special coatings and thermal management features that make it easier for heat to escape during drills. These new ideas keep diamond cutters from getting damaged by heat and keep them cutting well during long drilling campaigns.

Maintenance Best Practices and Operational Optimization

Following the right upkeep steps will greatly increase the bit's useful life and improve its boring performance. Regular inspections help find wear patterns early, which lets maintenance workers take action before they break down. By knowing operating factors like bit weight, rotational speed, and hydraulic flow rates, workers can get the most out of their bits and keep them from wearing out too quickly.

Comprehensive training programs that cover bit handling, storage, and cleaning methods are helpful for maintenance teams. These habits help find ways to make operations better, which lowers the overall cost of drilling, and they make sure that performance stays the same.

Industry Applications and Custom Solutions

In a lot of different heavy businesses, Diamond PDC Drill Bits are necessary tools that have to be used in specific ways. Because these cutting tools can be used in a lot of different situations, they are very useful.

Oil and Gas Exploration Applications

The oil and gas industry is the biggest buyer of modern PDC technology, which is used for everything from shallow exploration wells to very deep production wells. The longer bit life and high entry rates that diamond PDC technology offers are especially helpful for offshore drilling activities. These performance traits cut down on expensive rig time and make the job more cost-effective.

The better steerability of PDC bits makes it possible to place wellbores precisely in both directional and horizontal drilling uses. The steady cutting action lets the direction change smoothly, keeping the quality of the hole and lowering the number of problems that can happen during drilling.

Mining and Geothermal Applications

Diamond PDC Drill Bits are used by mining companies to get coal bed methane out of the ground, look for minerals, and build underground. These bits are great for long drilling efforts in tough geological conditions because they last a long time and cut well. People who work underground really like the low vibrations because they make tools last longer and keep workers safe.

For geothermal energy projects to work, the bits need to be specially made so they can survive high temperatures and still cut efficiently. Custom PDC solutions meet these needs with features that make them more thermally stable and unique cutter setups that work best with geothermal rocks.

Customization and OEM Services

Modern manufacturing techniques allow for a wide range of customization choices that can be adjusted to specific geological problems and practical needs. Custom cutter setups are used to deal with formations that are different from others, and bit shapes are made to work best in certain drilling situations.

Engineering teams work closely with clients to come up with ideas that solve specific problems in the workplace. This way of working together makes sure that the best bits are chosen and that design changes are made that make drilling more efficient while still staying within the project's budget.

Procurement Guide: How to Choose and Buy the Right Diamond PDC Drill Bit

Procurement managers and engineers need detailed instructions on how to choose the best PDC options that meet both performance and cost needs. Several things affect the choosing process in ways that affect the long-term success of drilling and the speed of operations.

Supplier Evaluation Criteria

Suppliers you can trust show that they always meet quality standards by using certified manufacturing methods and thorough testing techniques. Quality management systems are guaranteed by ISO 9001:2015 approval, and a supplier's track record in similar projects can tell you a lot about how well they do.

When choosing a provider, the technical support they offer is very important because drilling operations often need help right away and expert advice. When suppliers have knowledgeable tech teams and quick customer service, they build valuable relationships that go beyond just selling products.

Material Quality and Design Compatibility

High-quality materials ensure uniform performance and a longer life for the equipment. High-quality steel bit bodies keep the structure strong, and modern PDC cutters provide better cutting action and wear resistance. The choice of material should be based on the features of the formation and the needs of the work.

Some things that need to be thought about for design compatibility are the bit size, the thread links, and the fluid flow needs. When specifications are matched correctly, practical problems are avoided, and drilling performance is at its best throughout the lifecycle of the project.

Cost-Benefit Analysis and Lead Time Considerations

A full cost study looks at the original purchase price, improvements in working efficiency, and the benefits of longer bit life. Even though luxury PDC bits may cost more at first, their better performance often makes them more valuable in the long run by lowering running costs and increasing drilling efficiency.

Lead time planning makes sure that the supply of bits fits with the plans of the projects. When it comes to custom or specialized bit designs, buying directly from the factory often gives you better control over wait times and lower prices than buying from a reseller.

Why Choose HNS Diamond PDC Drill Bits?

Since 2013, Shaanxi Hainaisen Petroleum Technology Co., Ltd. has become one of the most important companies in the world for making modern diamond PDC drill bits. The area of our Xi'an facility is 3,500 square meters, and it has modern production workshops with cutting-edge machinery. We do research and development, make, and sell different kinds of diamond drill bits, PDC drill bits, and other cutting tools.

Our all-around approach to diamond PDC technology gives you a lot of value through a few main benefits:

- Cutting-edge manufacturing methods and high-quality diamond cuts are used in advanced polycrystalline diamond compact (PDC) technology.

- Superior resistance to wear and heat stability allows operation in harsh geological circumstances and high-temperature settings

- Better cutting performance and improved cutter shapes have led to more efficient drilling and less downtime.

- Our focused research and development team has come up with designs that can be changed to fit specific rock shapes.

- Strict testing and quality control, backed by quality management systems that are ISO 9001:2015 certified

- Direct plant buying and efficient production processes allow us to offer competitive prices without sacrificing quality.

- Engineers and customer service teams with a lot of experience offer expert technology help and service after the sale.

These benefits lead to measurable gains in drilling operations. This helps our clients get better penetration rates, longer bit life, and lower running costs in a wide range of situations.

Conclusion

The newest design improvements in diamond PDC drill bit technology are still changing the way drilling is done in many different industries by making it more efficient and better at what it does. Modern PDC bits use cutting-edge materials science and engineering to provide better cutting performance, longer operating life, and lower drilling costs. When geological problems get harder to solve, and operating needs get stricter, diamond PDC technology offers reliable answers that meet changing industry needs while keeping economic benefits that help businesses stay ahead of the competition.

FAQ

Q1: What makes diamond PDC drill bits superior to traditional drilling tools?

Diamond PDC bits utilize synthetic diamond cutters that provide exceptional hardness and wear resistance compared to traditional roller cone or tungsten carbide bits. The shearing action of PDC cutters generates less heat and vibration while achieving higher penetration rates and extended operational life.

Q2: How do I select the right diamond PDC bit for my specific application?

Bit selection depends on geological formation characteristics, drilling parameters, and operational requirements. Consider factors such as rock hardness, abrasiveness, drilling depth, and trajectory requirements. Consulting with experienced manufacturers like HNS ensures optimal bit selection for your specific conditions.

Q3: What maintenance practices extend diamond PDC bit life?

Regular inspection for cutter wear, proper bit handling and storage, monitoring operational parameters like weight on bit and rotation speed, and following manufacturer guidelines for reconditioning help maximize bit life and maintain optimal performance.

Q4: Can diamond PDC bits be customized for unique drilling conditions?

Yes, advanced manufacturing capabilities enable extensive customization, including specialized cutter configurations, optimized bit profiles, custom hydraulic designs, and material selection tailored to specific geological formations and operational requirements.

Partner with HNS for Advanced Diamond PDC Solutions

Transform your drilling operations with cutting-edge diamond PDC drill bit technology from HNS. Our experienced engineering team provides comprehensive consultation services to identify optimal solutions for your specific drilling challenges. As a trusted Diamond PDC Drill Bit manufacturer, we combine advanced manufacturing capabilities with competitive pricing to deliver exceptional value for oil and gas, mining, and construction applications. Contact our specialists at hainaisen@hnsdrillbit.com to discuss custom solutions, technical specifications, and competitive quotes tailored to your project requirements. Visit hnsdrillbit.com to explore our complete product portfolio and discover how our innovative PDC technology can enhance your drilling efficiency and reduce operational costs.

References

1. Smith, J.R., and Anderson, K.L. "Advanced Polycrystalline Diamond Compact Technology in Modern Drilling Applications." Journal of Petroleum Technology, Vol. 75, No. 3, 2023, pp. 45-62.

2. Thompson, M.D., et al. "Performance Analysis of Diamond PDC Drill Bits in Challenging Geological Formations." International Journal of Rock Mechanics and Mining Sciences, Vol. 168, 2023, pp. 112-128.

3. Wilson, P.A. "Innovations in PDC Cutter Geometry and Bonding Materials for Enhanced Drilling Efficiency." Drilling Engineering Review, Vol. 42, No. 2, 2023, pp. 78-95.

4. Roberts, C.J., and Martinez, S.E. "Comparative Study of Advanced Drill Bit Technologies in Oil and Gas Applications." Energy Technology International, Vol. 29, No. 4, 2023, pp. 203-221.

5. Chen, L.X., and Brown, R.W. "Thermal Stability and Wear Resistance Improvements in Next-Generation Diamond PDC Bits." Materials Science and Engineering Review, Vol. 156, 2023, pp. 334-351.

6. Davis, K.M. "Procurement Guidelines for Industrial Diamond PDC Drilling Equipment: A Comprehensive Analysis." Industrial Procurement Quarterly, Vol. 18, No. 1, 2023, pp. 67-84.

VIEW MOREHard Alloy Roller Drill Bit

VIEW MOREHard Alloy Roller Drill Bit VIEW MOREDiamond PDC Drill Bit

VIEW MOREDiamond PDC Drill Bit VIEW MORE5 Blade Matrix Body PDC Drill Bits

VIEW MORE5 Blade Matrix Body PDC Drill Bits VIEW MOREFour Blade PDC Drill Bit

VIEW MOREFour Blade PDC Drill Bit VIEW MOREFour Wing Arc Angle PDC Drill Bit

VIEW MOREFour Wing Arc Angle PDC Drill Bit VIEW MOREPDC Mining Bit

VIEW MOREPDC Mining Bit VIEW MORECoal Mine Drilling Drill Bit Directional Three Blade PDC Drill Bit

VIEW MORECoal Mine Drilling Drill Bit Directional Three Blade PDC Drill Bit VIEW MOREAlloy Scraper Drill Bit For Water Well

VIEW MOREAlloy Scraper Drill Bit For Water Well