How Is a Drilling Bit for Oil and Gas Rig Constructed?

In current oil and gas production, a Drilling Bit For Oil And Gas Rig is one of the most advanced pieces of engineering ever made. These highly precise tools use cutting-edge manufacturing techniques, advanced metals, and diamond technology to make parts that can go through different types of rock up to thousands of feet deep. During building, cutting elements, bearing systems, and hydraulic channels are all put together into a single unit that can handle high temperatures, high pressures, and rough conditions while still digging perfectly for long periods of time.

Understanding Drilling Bits in the Oil and Gas Industry

In today's oil and gas drilling operations, every part has to be very precise and reliable. Drilling Bit For Oil And Gas Rig are the most important part because they connect the complicated drilling equipment to hard rock formations. These specialized tools have to keep working even in harsh situations that would destroy regular cutting tools.

Principal Functions and Core Components

The main job of any boring bit is to break up rock efficiently by cutting it with controlled force. Unlike regular building drill bits, oil rig drill bits have to keep working even when the rock isn't the same stiffness, handle a lot of fluid flow, and keep going for hundreds of hours without stopping. The rock-cutting action is done by the cutting elements, which are usually made up of polycrystalline diamond compact (PDC) blades or tungsten carbide inserts. These parts are placed across the bit face in a way that distributes the load evenly and improves cutting efficiency.

The bearing system is another important part that makes spinning smooth and supports huge axial and side forces. Advanced sealed bearing systems have many hurdles that keep drilling fluid from getting inside and keep the bearings oiled for longer periods of time. The bit body itself is the structure's base. It holds all the parts and provides hydraulic paths for drilling fluid to flow.

Engineering for Extreme Environments

Drilling sites have their own problems that can't be solved by other industry uses. Pressures can hit several thousand pounds per square inch, and temperatures often go above 300°F. In the meantime, cutting surfaces are constantly being worn down by very rough rock forms made up of quartz, granite, and other hard minerals. These problems are solved by our technical method, which includes choosing the right materials, managing heat, and using protective coatings.

In building, advanced metallurgy is very important. Specialized steel alloys give materials strength and toughness while still being easy to machine. The properties of materials are improved by heat treatment, which makes zones of varied hardness that combine cutting performance with structural integrity.

Types and Designs of Oil and Gas Drilling Bits

Drilling technology has changed over time to make different types of bits, each best suited to different rock types and drilling situations. Knowing about these differences helps procurement pros match the skills of a tool with the needs of a project.

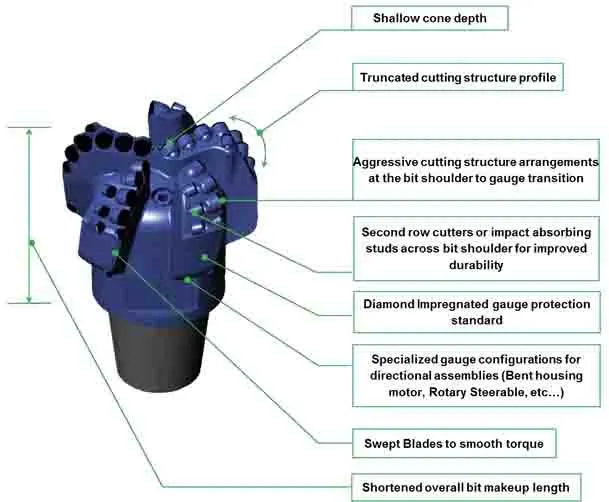

PDC (Polycrystalline Diamond Compact) Bits

PDC technology is the most important improvement in the design of a drilling bit, Drilling Bit For Oil And Gas Rig, in the last 30 years. These bits have cutting elements made of synthetic diamonds that are bound to tungsten carbide surfaces. This makes blades that are hard like diamonds and tough like carbides. The process of making them includes sintering diamond particles under very high temperatures and pressures. This makes tools with sharp edges that can be used to drill thousands of feet.

Modern PDC bit designs use complex cutter placement techniques that make the best use of power and debris removal. Engineers can use computer models to find the best cutter angles, spacing, and direction to get the best penetration rates with the least amount of wear. Cutting surfaces are kept cool and clean by an advanced hydraulic design that stops heat buildup that could damage diamond elements.

Roller Cone and Diamond Bit Technologies

Traditional roller cone bits are still useful in some cases, especially when working with soft materials or when long-lasting performance is needed. In these designs, cones that rotate and have steel teeth or tungsten carbide pieces that crush and chip rock through dynamic action are used. The rolling motion spreads wear across several cutting edges, which makes the tool last longer in tough circumstances.

Both natural and man-made diamond bits are used for specific tasks in very hard rock types where other technologies fail. Industrial-grade diamonds are set in a metal framework in these bits, which makes them the best at cutting granite, quartzite, and other tough materials.

Material Innovations and Performance Enhancements

New advances in cutting element technology have focused on making diamonds better and finding better ways to bond them together. Thermally stable diamond materials don't break down at high temperatures, and advanced carbide surfaces are better at resisting impact. When protective coats are put on cutting elements, they stop drilling fluids from attacking them chemically and reduce friction.

Construction Process and Technical Specifications of Drilling Bits

Precision cutting, advanced material processing, and strict quality control at every stage of production are needed to make professional-grade drilling bits. We use cutting-edge 5-axis machining centers and CNC machine tools at our site to make sure that the dimensions are correct for current drilling operations.

Raw Material Selection and Processing

The building process starts with carefully choosing high-quality steel that is made to be used for cutting. Chemical testing and mechanical testing are used to make sure that these products meet API standards. The steel billets are then put through controlled heating and shaping steps that create the basic shape of the bit body while keeping the best grain structure.

In a similar process called PDC cutter production, diamond powder sintering is done in harsh conditions. Before they are mixed with metal bonds and put under pressures of more than 1 million PSI at temperatures above 2500°F, industrial diamond particles are carefully sorted by size and quality. This method makes cutting elements with a strong carbide back and evenly spaced diamonds.

Precision Machining and Assembly Operations

Computer-controlled machining centers make the bit body, Drilling Bit For Oil And Gas Rig, fit perfectly, making the complex three-dimensional surfaces needed for the best flow of fluid and placement of the cutter. To make sure the right cutting shape and load distribution, each cutter pocket must be placed to the level of a micron. Modern molding systems make sure that the quality of each production run is the same while also being able to adapt to the unique needs of each application.

The process of putting the parts together includes brazing PDC cutters into place using special supports that keep them perfectly aligned. Controlled oxygen furnaces keep oxidation from happening during the brazing cycle. This makes sure that the bonds between the cuts and the bit body are strong and reliable. Verification of dimensions, non-destructive testing, and performance proof through controlled drilling tests are all examples of quality control methods.

Meeting Industry Standards and Certifications

All building methods follow the guidelines set out in API RP 13C for drilling bit performance and size standards. Quality management systems based on ISO 9001 make sure that regular manufacturing methods are used and that production can be tracked. Our testing methods go beyond what is required by the industry. They include rapid wear testing, vibration analysis, and temperature cycling to make sure that the products will work well for a long time.

Maintenance, Performance Optimization, and Common Problems

Effective drilling bit management includes more than just choosing the right bit. It also includes the right way to handle, store, and keep an eye on operations to get the best return on investment. Understanding typical failure modes and taking steps to stop them has a big effect on the economics of drilling and the success rates of projects.

Preventive Maintenance and Handling Protocols

Before you start drilling, you should carefully check the bit's cutting elements, gauge safety, and hydraulic ports to make sure they are in good shape. Corrosion and pollution that could hurt performance can be avoided by storing things in clean, dry places. For transportation, protective cases are needed that keep the bit's shape and stop impact damage to the cutting elements.

Monitoring drilling factors all the time during activities helps find problems early on, before they lead to catastrophic failure. To keep things from wearing out too quickly or getting too hot, the bit's weight, its spinning speed, and the flow rates of its hydraulics must all stay within certain limits. Real-time data analysis lets workers improve speed and make bits last longer.

Common Failure Modes and Solutions

The most common way something breaks is through cutter wear, Drilling Bit For Oil And Gas Rig, which usually happens when normal abrasive contact with rock forms. By understanding wear trends, operators can change the settings of the drill to make the bit last longer. Too much wear usually means that the bit is too heavy or that the hydraulics aren't cleaned well enough.

Contamination, poor greasing, or high working temperatures can all cause bearings to fail. Most pollution can't get into modern sealed bearing systems, but extreme conditions may be too much for the protections to handle. Checking the drilling settings and bearing covers regularly helps keep things from breaking down too soon.

Most of the time, contact loading or heat damage causes cutters to break. When drilling correctly, shock loads are kept to a minimum, and enough fluid flow keeps things from getting too hot. When a cutter is lost, replacing the bit right away keeps the hole quality and keeps the remaining cutters from getting damaged.

Procurement Considerations: Choosing and Buying Drilling Bits for Oil and Gas Rigs

To buy drilling bits successfully, you have to find a balance between the need for technical performance and the need to stay within budget and with practical tasks. When making a choice, many things must be taken into account that can affect both the short-term success of the digging and the long-term efficiency of the operations.

Defining Technical Requirements and Performance Criteria

An important part of effective procurement is a full study of the drilling conditions, which should include the features of the formation, the predicted drilling parameters, and the performance goals. Rock hardness, abrasiveness, and shear strength directly affect the choice of bit. On the other hand, practical factors like the length of time planned for drilling and the direction that needs to be drilled in affect design choices.

Expectations for entry rate, bit life, and hole quality should all be part of performance metrics for Drilling Bit for Oil and Gas Rig. These things help set reasonable performance standards and make it possible to compare different bit choices in a useful way. When setting performance standards, it's better to look at the whole drilling program than just one or two holes at a time. This is because consistent results across many uses are often more valuable overall than excellent performance in a few cases.

Supplier Evaluation and Partnership Development

When choosing a supplier, you have to look at their technical skills, the standard of their products, and their support system, as well as their prices. Manufacturers that have been around for a while and have a track record of reliability usually offer more stable performance and better long-term support. When choosing suppliers, you should look at how well they can provide customized solutions, expert help during drilling operations, and quick service when issues arise.

Quality certificates, the ability to make things, and investments in research and development all show that a provider is dedicated to always getting better. Companies with dedicated engineering teams and up-to-date factories are better able to deal with new drilling problems and come up with creative solutions. Strong ties with suppliers often give you benefits that go beyond just the transaction itself. For example, you may be able to get new technologies faster and have unique products made just for you.

Our dedication to quality greatness comes from having strong research and development resources and modern production facilities. With our experienced engineering teams and up-to-date production facilities, we can provide unique solutions that solve specific drilling problems at prices that are highly competitive.

HNS Company Introduction and Product & Service Information

Since it was founded in Xi'an in 2013, Shaanxi Hainaisen Petroleum Technology Co., Ltd. has become one of the best companies in the world at making high-performance drilling solutions. Our wide range of skills includes researching and creating, making, and selling different kinds of diamond drill bits, PDC drill bits, and specialized drilling tools. We back these up with unified technology solutions that cover all drilling problems.

Manufacturing Excellence and Technical Capabilities

Our 3,500-square-meter building is the best place in the world to make modern drilling bits. It has state-of-the-art production rooms with the best processing tools in the business. We can keep up high-quality standards and get the exact measurements needed for the best drilling performance by combining 5-axis machining centers, precision CNC machine tools, and automatic welding production lines.

The specialized research and development team works on making unique bits that meet the needs of customers in a wide range of drilling situations. Because we have this engineering skill, we can make drill bits that are perfectly suited to specific geological conditions or operating limitations that normal goods can't handle well.

Product Portfolio and Performance Advantages

Our line of Drilling Bit For Oil And Gas Rig products performs exceptionally well, thanks to a number of key benefits that have a direct effect on the cost and effectiveness of digging. Here are the main things that make our drilling options stand out:

- Better resistance to wear and temperature stability allows longer drilling operations in difficult rocks while keeping cutting performance stable.

- Engineering tuning for different layers guarantees dependable performance in medium-hard rock types like shale, limestone, sandstone, and gypsum.

- Better drilling efficiency and less downtime thanks to cutting-edge cutter technology and hydraulic design that boosts entry rates

- Designs that can be changed to fit individual project needs and operational factors ensure the best performance.

- A lot of money is spent on research and development, which leads to constant new ideas and expert help throughout the lifecycle of a product.

These benefits successfully solve the most important problems that modern drilling operations face, leading to measured changes in the speed of drilling, the reliability of operations, and the overall economics of the project.

Technical Specifications and Application Range

Our drilling bits work within carefully designed limits that make them work best in a wide range of drilling situations. Speeds run from 80 to 300 RPM, drilling pressures from 10 to 100 KN, and flow rates from 20 to 35 LPS. The operational needs of the most common drilling uses are met by these standards, while also leaving room for special operations.

The range of applications includes oil and gas research, both offshore and ashore, geothermal energy development, deep-water drilling, and both horizontal and directional drilling. This adaptability makes sure that the results are the same in all drilling situations, while still providing the dependability that tough jobs need.

Conclusion

The process of making drilling bits for oil and gas rigs is a complex mix of cutting-edge materials science, precise manufacturing, and new engineering ideas. Procurement professionals can make smart choices that improve drilling performance and operating economics by understanding how cutting elements, bearing systems, and hydraulic design work together. The change from simple roller cone designs to advanced PDC technology shows how the industry is always coming up with new ideas to make things more reliable and efficient. To have successful drilling operations, you need to choose the right bit technologies, follow the right maintenance procedures, and work with manufacturers who offer full expert help throughout the drilling process.

FAQ

Q1: How do geological factors influence drilling bit selection?

Geological characteristics represent the primary consideration in bit selection, as formation properties directly impact cutting requirements and operational parameters. Rock hardness, abrasiveness, and compressive strength determine the type of cutting elements needed, while formation stability affects hydraulic requirements and cutter placement strategies. Heterogeneous formations may require compromise designs that balance performance across varying conditions.

Q2: What role does advanced bit technology play in improving drilling efficiency?

Advanced bit technologies enhance drilling efficiency through multiple mechanisms, including optimized cutting element placement, improved hydraulic design, and enhanced materials engineering. Modern PDC cutters maintain sharper cutting edges longer than traditional alternatives, while sophisticated bit body designs improve debris removal and reduce energy consumption. The combination of these factors typically results in 15-30% improvements in penetration rates compared to conventional designs.

Q3: What warranty and after-sales support do manufacturers typically provide?

Comprehensive warranty coverage typically includes manufacturing defects and premature failure due to material or construction issues. Support services encompass technical consultation during drilling operations, performance analysis, and replacement or credit programs for qualifying failures. Leading manufacturers maintain field service capabilities and provide real-time technical support to optimize drilling performance and address operational challenges.

Partner with HNS for Superior Drilling Bit Solutions

HNS stands ready to transform your drilling operations through our advanced Drilling Bit For Oil And Gas Rig technology and comprehensive technical support. Our engineering team collaborates with clients to develop customized solutions that address specific geological challenges while optimizing drilling economics. Contact our specialists at hainaisen@hnsdrillbit.com to discuss your drilling requirements and discover how our proven drilling bit manufacturer capabilities can enhance your operational success. Visit hnsdrillbit.com to explore our complete product portfolio and technical resources designed for demanding drilling applications.

References

1. Smith, J.R., "Advanced Materials in Drilling Bit Construction," Journal of Petroleum Engineering Technology, Vol. 45, No. 3, 2023.

2. Johnson, M.K. and Williams, P.D., "PDC Cutter Technology and Performance Optimization," International Drilling Conference Proceedings, Houston, 2022.

3. Brown, A.L., "Quality Control in Drilling Bit Manufacturing," API Technical Standards Review, 2023.

4. Davis, R.C., "Failure Analysis and Prevention in Oil Field Drilling Bits," Society of Petroleum Engineers Technical Paper, 2022.

5. Thompson, S.M., "Hydraulic Design Principles for Modern Drilling Bits," Drilling Engineering Handbook, 3rd Edition, 2023.

6. Anderson, K.W., "Cost-Benefit Analysis of Advanced Drilling Bit Technologies," Energy Economics Quarterly, Vol. 28, No. 2, 2023.

VIEW MOREDiamond Coal Mine Picks

VIEW MOREDiamond Coal Mine Picks VIEW MORE5 Blade Matrix Body PDC Drill Bits

VIEW MORE5 Blade Matrix Body PDC Drill Bits VIEW MOREPDC Bit For Well Drilling

VIEW MOREPDC Bit For Well Drilling VIEW MOREPDC Core Drill Bit With 8 Blades For Hole Drilling Used In Mining

VIEW MOREPDC Core Drill Bit With 8 Blades For Hole Drilling Used In Mining VIEW MOREPDC Mining Bit

VIEW MOREPDC Mining Bit VIEW MOREDrill Bits For Oil Drilling

VIEW MOREDrill Bits For Oil Drilling VIEW MOREHigh Quality PDC Drill Bits

VIEW MOREHigh Quality PDC Drill Bits VIEW MOREFive Blades Oil Well Drill Head

VIEW MOREFive Blades Oil Well Drill Head