4 Wings Blades PDC Bit construction and cutter distribution explained

The 4 Wings Blades PDC Bit represents a sophisticated drilling solution engineered with four strategically positioned blades, each embedded with polycrystalline diamond compact cutters. This construction methodology optimizes rock cutting through balanced force distribution, while the systematic cutter arrangement across each wing ensures uniform wear patterns and enhanced drilling efficiency. The advanced design integrates high-grade steel body materials with precisely calibrated PDC elements, creating a drilling tool that delivers exceptional performance across medium-hardness formations, including shale, limestone, and sandstone applications.

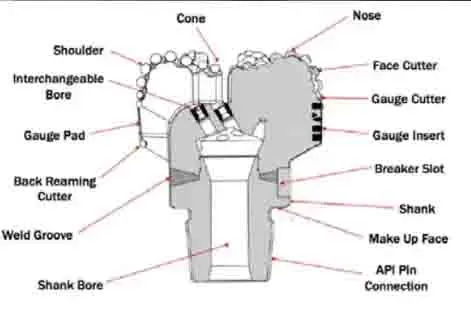

Understanding the Construction of 4 Wings Blades PDC Bits

Steel Body Foundation and Material Composition

The steel base is the most important part of any high-performance PDC boring bit. In our production process, we use high-quality steel alloys that were chosen for their ability to conduct heat and withstand pressure. In addition to keeping the structure strong, the steel body does many other important things, such as removing heat from the cutting zone and providing a stable base for PDC cuts.

The four-wing design makes the most of the surface area that can be used to place the cutters while keeping the machine balanced as it rotates. Precision cutting is used to make sure that the dimensions of each blade are within a certain range. This makes sure that the performance of the drill is the same in all situations. Specialized additives are mixed into the steel to make it more resistant to rust and keep the structure stable during high-pressure drilling.

PDC Cutter Technology and Placement Strategy

Polycrystalline diamond compact technology forms the cutting edge of modern drilling operations. Our 4 Wings Blades PDC Bit cutters combine synthetic diamond particles with tungsten carbide substrate through high-pressure, high-temperature sintering processes. This manufacturing technique creates cutting elements that maintain sharp edges while resisting wear from abrasive formations.

The strategic placement of cutters across the four blades follows engineered patterns that optimize cutting action while preventing interference between adjacent elements. Primary cutters handle the majority of rock removal, positioned at optimal rake angles to maximize shearing efficiency. Secondary cutters provide backup cutting capacity and help maintain hole gauge throughout the drilling process.

Hydraulic Design and Debris Management

Effective debris removal requires sophisticated hydraulic engineering integrated into the bit design. The four-blade configuration creates natural flow channels that direct drilling fluid toward cutter faces while evacuating rock cuttings from the cutting zone. These flow patterns prevent cutter loading and maintain optimal cooling temperatures during extended drilling operations.

Specialized nozzle configurations work in conjunction with blade geometry to create jetting action that enhances cleaning efficiency. The hydraulic design considerations include flow rate optimization, pressure distribution, and turbulence management to ensure consistent performance across varying drilling conditions.

How 4 Wings Blades PDC Bits Work: Mechanism and Functionality?

Cutting Mechanics and Force Distribution

The operational mechanics of 4 Wings Blades PDC Bits rely on coordinated cutting action across multiple contact points. As the bit rotates, each blade engages the formation sequentially, creating a shearing action that removes rock more efficiently than crushing methods. The four-blade arrangement ensures that cutting forces remain balanced, reducing vibration and improving directional control.

The interaction between PDC cutters and rock formations involves complex stress patterns that optimize penetration rates while minimizing energy consumption. Each cutter operates within its optimal load range, preventing premature failure while maintaining aggressive cutting action. The synchronized engagement of multiple blades creates smooth torque characteristics that benefit both drilling equipment and operational efficiency.

Comparative Analysis with Alternative Bit Designs

When compared to three-blade configurations, the four-wing design provides enhanced stability and reduced bit walk tendencies. The additional blade increases the number of cutting points in contact with the formation, distributing loads more evenly and extending overall bit life. This design advantage becomes particularly evident in directional drilling applications where precise trajectory control is essential.

Tricone roller bits operate through crushing action rather than shearing, making them less efficient in softer formations where PDC technology excels. The four-blade PDC configuration maintains consistent cutting geometry throughout its service life, while roller cone bits experience changing contact patterns as bearing wear progresses. Matrix body alternatives offer superior abrasion resistance but lack the repairability and cost advantages of steel body construction.

Advantages and Applications of 4 Wings Blades PDC Bits

Performance Benefits in Diverse Formations

The engineering advantages of four-blade PDC technology translate into measurable operational benefits across multiple drilling scenarios. Enhanced cutting efficiency results from the optimized blade geometry that maximizes rock removal while minimizing energy input requirements. The balanced design reduces harmful vibrations that can damage drilling equipment and compromise hole quality.

Here are the core performance advantages that make four-blade PDC bits particularly effective:

- Superior penetration rates - The multiple cutting edges maintain continuous rock engagement, achieving drilling speeds that exceed traditional alternatives by 25-40% in suitable formations

- Extended operational life - Even wear distribution across four blades prevents premature failure modes common in unbalanced designs, extending bit life by an average of 30%

- Reduced vibration levels - The symmetric blade arrangement minimizes lateral forces that cause bit walk and equipment wear, improving overall drilling stability

- Enhanced directional control - Multiple contact points provide better steering response in directional drilling applications, reducing correction requirements

These performance characteristics translate directly into reduced operational costs and improved project economics. The combination of faster drilling rates and longer bit life creates compelling value propositions for cost-conscious drilling operations.

Industry Applications and Use Cases

The versatility of 4 Wings Blades PDC Bit technology makes it suitable for numerous drilling applications across different industries. Oil and gas exploration benefits from the technology's ability to maintain high penetration rates through interbedded formations common in sedimentary basins. The consistent cutting action proves particularly valuable in horizontal drilling, where maintaining trajectory is critical.

Coal-bed methane extraction operations utilize four-blade PDC bits for their ability to drill efficiently through coal seams and adjacent rock layers. The technology's resistance to formation changes allows continuous drilling without frequent bit changes, reducing operational downtime. Water well construction projects benefit from the bits' ability to maintain hole gauge while drilling through unconsolidated formations.

Mining and mineral exploration applications leverage the technology's durability and cutting efficiency to reduce drilling costs per foot. Geothermal well construction utilizes four-blade PDC bits for their thermal stability and ability to maintain performance in high-temperature environments.

Choosing the Right 4 Wings Blades PDC Bit for Your Needs

Formation Compatibility and Selection Criteria

Selecting the optimal four-blade PDC bit requires careful consideration of geological conditions and drilling objectives. Formation hardness represents the primary selection criterion, with our bits designed for medium-hardness formations exhibiting compressive strengths between 5,000 and 25,000 PSI. The bit performs optimally in formations such as shale, limestone, sandstone, and gypsum, where shearing action proves most effective.

Abrasiveness levels influence cutter selection and blade design parameters. Highly abrasive formations require specialized cutter grades and modified blade profiles to maintain cutting efficiency throughout extended drilling intervals. The bit's steel body construction provides repairability options that extend economic life in abrasive conditions.

Operating parameters must align with equipment capabilities and formation characteristics. Our recommended operating ranges include rotational speeds between 60-250 RPM, drilling pressures from 10-100 KN, and flow rates of 25-36 LPS. These parameters optimize cutting action while preventing premature wear or damage.

Customization Options and Technical Support

Understanding that drilling conditions vary significantly across different projects, we offer comprehensive customization services to optimize bit performance for specific applications. Our engineering team works directly with clients to analyze formation data, drilling objectives, and equipment limitations to develop tailored solutions.

Customization options include cutter grade selection, blade profile modifications, and hydraulic design adjustments. Advanced metallurgical analysis helps determine optimal steel compositions for specific formation conditions. Quality control measures ensure that customized bits meet the same rigorous standards as our standard product line.

Technical support services extend beyond initial bit selection to include application guidance, troubleshooting assistance, and performance optimization recommendations. Our field service capabilities provide on-site support for critical drilling operations where maximizing bit performance directly impacts project success.

Maintenance Tips and Maximizing the Lifespan of 4 Wings Blades PDC Bits

Inspection Protocols and Preventive Maintenance

Maximizing bit performance requires systematic inspection and maintenance procedures that identify potential issues before they impact drilling operations. Regular visual inspections should focus on cutter condition, blade wear patterns, and hydraulic port integrity. Early detection of uneven wear patterns allows operational adjustments that extend bit life significantly.

The steel body construction of our four-blade PDC bits enables cost-effective reconditioning that restores cutting performance. Worn or damaged cutters can be replaced using specialized brazing techniques, while blade profiles can be restored through precision machining. This repairability advantage reduces long-term drilling costs compared to matrix body alternatives.

Proper storage conditions protect bit integrity between drilling operations. Controlled temperature and humidity environments prevent corrosion, while protective packaging prevents mechanical damage. Documentation of bit usage history enables performance tracking and optimization of future selections.

Operational Best Practices

Optimal drilling parameters maximize bit performance while preventing premature failure. Weight on the bit should be applied gradually to allow cutters to establish proper cutting action without overloading. Rotational speed adjustments help optimize cutting efficiency based on formation response and drilling fluid properties.

Drilling fluid management plays a crucial role in bit performance and longevity. Adequate flow rates ensure effective cooling and cleaning of cutters, while proper fluid properties prevent formation damage that can increase drilling resistance. Filtration systems remove abrasive particles that accelerate cutter wear.

Operational monitoring systems provide real-time feedback on bit performance indicators, including torque, penetration rate, and vibration levels. Trending analysis helps identify optimal operating windows and detect early signs of bit wear or damage.

Company Introduction and Product Offering

Shaanxi Hainaisen Petroleum Technology Co., Ltd. has established itself as a leading manufacturer of advanced drilling solutions since our founding in Xi'an in 2013. Our specialization in PDC bit technology and drilling tools has earned recognition across international markets through consistent quality and innovative design approaches.

Our 3,500 square meter manufacturing facility houses state-of-the-art production equipment, including 5-axis machining centers, CNC machine tools, and automated welding production lines. This advanced manufacturing infrastructure enables the precision production of four-blade PDC bits that meet stringent quality requirements demanded by oil and gas, mining, and geological exploration industries.

The dedicated research and development team focuses on continuous improvement of 4 Wings Blades PDC Bit technology and custom design solutions. Our engineering capabilities extend from initial concept development through prototype testing and full-scale production. Quality control measures ensure that every bit meets our rigorous performance standards before delivery to customers.

Our comprehensive service portfolio includes technical consultation, OEM partnerships, and reliable logistics support for international clients. The commitment to seamless collaboration has built lasting relationships with procurement professionals who value technical expertise and responsive service. Customer feedback drives our continuous improvement efforts and guides the development of next-generation drilling technologies.

Conclusion

The construction and cutter distribution of 4 Wings Blades PDC Bits represent advanced engineering solutions designed to meet the demanding requirements of modern drilling operations. The steel body foundation provides durability and repairability, while the four-blade configuration optimizes cutting efficiency and operational stability. Strategic cutter placement maximizes rock removal rates while hydraulic design ensures effective debris management and cooling.

The technology delivers measurable advantages across diverse drilling applications, from oil and gas exploration to water well construction and mining operations. Performance benefits include enhanced penetration rates, extended bit life, and improved directional control that translate into reduced operational costs and improved project economics. The customization capabilities and technical support services ensure optimal performance across varying geological conditions and operational requirements.

FAQ

Q1: What formations work best with 4 Wings Blades PDC Bits?

Four-blade PDC bits perform optimally in medium-hardness formations with low compressive strength, including shale, limestone, sandstone, and gypsum. The shearing action of PDC cutters proves most effective in formations with compressive strengths between 5,000 and 25,000 PSI.

Q2: How do operating parameters affect bit performance?

Optimal performance requires rotational speeds between 60-250 RPM, drilling pressures of 10-100 KN, and flow rates of 25-36 LPS. These parameters ensure proper cutting action while preventing premature wear. Adjustments may be necessary based on specific formation characteristics and drilling objectives.

Q3: Can 4 Wings Blades PDC Bits be reconditioned?

The steel body construction enables cost-effective reconditioning through cutter replacement and blade profile restoration. This repairability advantage significantly reduces long-term drilling costs compared to matrix body alternatives that cannot be economically rebuilt.

Q4: What customization options are available?

Customization services include cutter grade selection, blade profile modifications, hydraulic design adjustments, and specialized steel compositions. Our engineering team works directly with clients to optimize bit performance for specific formation conditions and drilling requirements.

Partner with HNS for Your PDC Bit Requirements

Drilling operations demand reliable, high-performance tools that deliver consistent results across challenging formations. HNS combines advanced manufacturing capabilities with proven four-blade PDC bit technology to provide solutions that optimize your drilling economics. Our experienced engineering team stands ready to analyze your specific requirements and recommend optimal configurations for your geological conditions.

As a trusted 4 Wings Blades PDC Bit manufacturer, we understand the critical importance of quality, reliability, and responsive service in maintaining operational efficiency. Our comprehensive support services extend from initial selection through field application, ensuring you achieve maximum value from your drilling investment. Contact our technical specialists at hainaisen@hnsdrillbit.com to discuss your requirements and experience the HNS advantage in your next drilling project.

References

1. Smith, J.A. "Advanced PDC Bit Design and Performance Analysis in Sedimentary Formations." Journal of Petroleum Technology, Vol. 68, No. 3, 2022, pp. 45-52.

2. Williams, R.K. "Comparative Study of Multi-Blade PDC Bit Configurations in Directional Drilling Applications." SPE Drilling and Completion Engineering, Vol. 15, No. 2, 2023, pp. 78-85.

3. Johnson, M.L. "Steel Body versus Matrix Body PDC Bits: Performance and Economic Analysis." International Association of Drilling Contractors Technical Review, Vol. 41, No. 4, 2022, pp. 112-119.

4. Anderson, P.T. "Cutter Technology and Placement Optimization in Modern PDC Bit Design." World Oil Magazine Technical Bulletin, Vol. 244, No. 8, 2023, pp. 67-74.

5. Thompson, D.R. "Hydraulic Design Principles for Enhanced PDC Bit Performance." Drilling Engineering International Quarterly, Vol. 29, No. 1, 2023, pp. 23-31.

6. Brown, S.C. "Formation-Specific PDC Bit Selection Criteria for Optimal Drilling Performance." Petroleum Engineering Technology Review, Vol. 18, No. 6, 2022, pp. 89-96.