What Materials Are Used in Seven Blade Wing Oil Drill Bits?

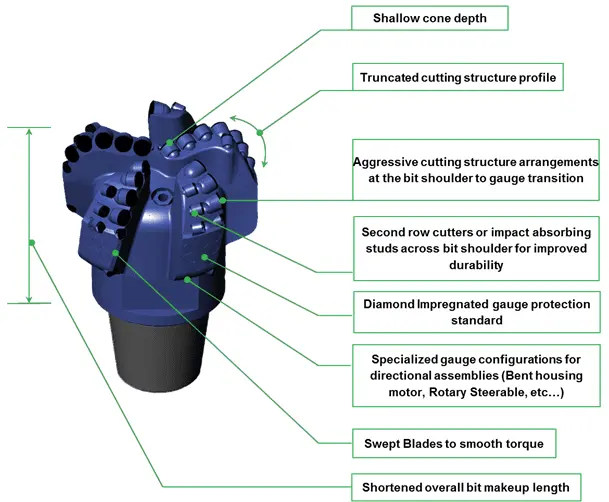

The Seven Blade Wing Oil Drilling Drill Bit speaks to a apex of building in the oil and gas investigation industry. These modern apparatuses are created from a assortment of high-performance materials, each chosen for its one of a kind properties and capacity to withstand the extraordinary conditions experienced amid penetrating operations. The essential components of these penetrate bits incorporate high-strength steel bodies, progressed polycrystalline precious stone compact (PDC) cutters, and specialized amalgams for improved solidness. The steel body of a Seven Edge Wing Oil Boring Bore Bit serves as the establishment, giving basic keenness and back for the cutting components. This body is ordinarily made from premium-grade steel combinations, carefully chosen for their strength-to-weight proportion and resistance to erosion. The PDC cutters, which are dependable for the real rock-cutting activity, are composed of a layer of manufactured precious stone particles fortified to a tungsten carbide substrate. This combination offers uncommon hardness and wear resistance, vital for keeping up execution in rough arrangements. Furthermore, these penetrate bits regularly join specialized coatings and hardfacing materials to encourage upgrade their strength and effectiveness. These may incorporate tungsten carbide lattice materials, diamond-impregnated embeds, and progressed ceramic composites. The choice and course of action of these materials are carefully built to optimize the bit's execution over a run of geographical arrangements, guaranteeing most extreme penetrating proficiency and life span in the challenging situations experienced amid oil and gas exploration.

High-Strength Alloys: Balancing Durability and Performance

The foundation of any high-quality Seven Blade Wing Oil Drilling Drill Bit lies in its use of high-strength alloys. These materials are crucial for maintaining structural integrity under the extreme pressures and temperatures encountered during drilling operations. The alloys used in modern drill bits are the result of decades of metallurgical research and development, aimed at creating materials that can withstand the harsh conditions of deep-earth drilling while maintaining optimal performance.

Advanced Steel Alloys

One of the essential materials utilized in the development of Seven Edge Wing Oil Penetrating Penetrate Bits is progressed steel amalgams. These are not your regular steels, but or maybe specialized details outlined particularly for the oil and gas industry. These amalgams ordinarily contain a carefully adjusted blend of components such as chromium, nickel, molybdenum, and vanadium. Each of these components contributes interesting properties to the last alloy:

- Chromium enhances corrosion resistance and hardenability

- Nickel improves toughness and ductility

- Molybdenum increases strength at high temperatures

- Vanadium refines grain structure, improving overall strength

The result is a fabric that can keep up its basic keenness beneath the monstrous stresses of boring, stand up to erosion from introduction to different arrangement liquids, and withstand the tall temperatures created amid the penetrating process.

Tungsten Carbide

Another basic amalgam utilized in Seven Edge Wing Oil Boring Bore Bits is tungsten carbide. This fabric is prized for its extraordinary hardness and wear resistance, making it perfect for the cutting components of the penetrate bit. Tungsten carbide is ordinarily utilized in the shape of embeds or as a lattice fabric in which other cutting components are embedded.

The one of a kind properties of tungsten carbide stem from its composition: a blend of tungsten and carbon iotas in a particular crystalline structure. This structure gives the fabric its characteristic hardness, which approaches that of precious stone, whereas too giving a degree of durability that unadulterated jewel needs. In penetrate bit applications, tungsten carbide is frequently combined with a cobalt folio, which encourage upgrades its durability and permits for the creation of complex shapes.

Composite Materials: Enhancing Wear Resistance in Harsh Environments

While high-strength alloys form the backbone of Seven Blade Wing Oil Drilling Drill Bits, it's the incorporation of advanced composite materials that truly sets modern bits apart in terms of wear resistance and performance in harsh drilling environments. These composites are engineered to provide specific properties that enhance the bit's ability to cut through various rock formations efficiently while maintaining structural integrity over extended periods of operation.

Polycrystalline Diamond Compact (PDC) Cutters

Perhaps the most critical headway in penetrate bit innovation in later decades has been the improvement of Polycrystalline Precious stone Compact (PDC) cutters. These cutting components are a composite fabric comprising of precious stone particles sintered together with a metal catalyst beneath tall weight and tall temperature conditions. The result is a fabric that combines the extraordinary hardness of jewel with progressed sturdiness and warm stability.

PDC cutters are ordinarily fabricated as circles or studs, with a layer of manufactured precious stone fortified to a tungsten carbide substrate. This plan permits for great warm scattering and gives a vigorous base for mounting the cutter to the bore bit body. The jewel layer, being essentially harder than the shake arrangements experienced amid penetrating, keeps up a sharp cutting edge for amplified periods, diminishing the require for bit substitution and progressing generally penetrating efficiency.

Diamond-Impregnated Materials

In expansion to PDC cutters, Seven Edge Wing Oil Boring Bore Bits frequently consolidate diamond-impregnated materials in different components. These composites comprise of mechanical jewel particles implanted in a metal network, regularly made of tungsten carbide or other difficult metals. The jewel particles give extraordinary scraped spot resistance, whereas the metal network offers the vital sturdiness and permits for the creation of complex shapes.

Diamond-impregnated materials are especially valuable in zones of the penetrate bit that involvement tall wear rates but do not require a sharp cutting edge. For case, they may be utilized in gage cushions, which offer assistance keep up the borehole distance across, or in regions close the PDC cutters to give extra wear protection.

Ceramic Composites

Advanced ceramic composites are progressively finding applications in Seven Edge Wing Oil Boring Bore Bits, especially in ranges that require tall warm soundness and chemical inactivity. These materials, which may incorporate alumina, silicon carbide, or boron nitride, offer great wear resistance and can keep up their properties at the tall temperatures experienced amid penetrating operations.

Ceramic composites are regularly utilized in conjunction with other materials to make cross breed structures that optimize execution. For occasion, a bore bit might utilize ceramic-coated steel components in ranges that involvement tall disintegration from penetrating liquids, combining the quality of steel with the wear resistance of ceramics.

Material Selection: Optimizing for Different Geological Formations

The effectiveness of a Seven Blade Wing Oil Drilling Drill Bit is not solely dependent on the quality of its materials, but also on how well those materials are selected and arranged to tackle specific geological formations. The process of material selection for these drill bits is a complex one, requiring a deep understanding of both material science and geology.

Tailoring Material Properties to Formation Characteristics

Different rock formations present unique challenges to drill bits. Soft formations may require bits that can efficiently remove large volumes of material without balling up, while hard formations demand bits that can withstand extreme abrasion and impact forces. As a result, the materials used in Seven Blade Wing Oil Drilling Drill Bits are carefully chosen to match the expected drilling conditions:

- For soft formations, bits may incorporate larger PDC cutters with more aggressive cutting angles, supported by a steel body designed for rapid heat dissipation.

- Hard formations might call for smaller, more numerous PDC cutters with specialized geometries, mounted on a bit body with enhanced shock-absorption properties.

- Abrasive formations could require the use of additional wear-resistant materials, such as diamond-impregnated gauge pads or thermally stable polycrystalline (TSP) diamond elements.

Balancing Hardness and Toughness

One of the key challenges in fabric choice for Seven Edge Wing Oil Boring Bore Bits is striking the right adjust between hardness and durability. Amazingly difficult materials, whereas safe to wear, can be fragile and inclined to break beneath the energetic loads experienced amid boring. Alternately, harder materials may wear as well rapidly in rough formations.

To address this, bit designers often employ a layered approach to material selection:

- The cutting elements, typically PDC cutters, provide the necessary hardness for efficient rock cutting.

- The substrate or mounting system for these cutters is designed to absorb shock and distribute forces, often using tougher materials like specially treated steels or carbide composites.

- The bit body itself is engineered to provide overall structural integrity while allowing for some flexion to prevent catastrophic failure.

Adaptive Materials for Changing Conditions

As drilling operations often encounter multiple types of formations, modern Seven Blade Wing Oil Drilling Drill Bits are increasingly designed with adaptive materials that can perform well across a range of conditions. This might include:

- Thermally stable PDC cutters that maintain their properties over a wide temperature range.

- Composite materials with graded properties, providing different characteristics at different depths within the material.

- Smart materials that can change their properties in response to drilling conditions, such as shape memory alloys used in certain bit components.

By carefully selecting and arranging these advanced materials, manufacturers can create Seven Blade Wing Oil Drilling Drill Bits that are not only durable but also versatile enough to maintain high performance across various geological formations.

Conclusion

The materials utilized in Seven Blade Wing Oil Drilling Drill Bit speak to the cutting edge of fabric science and building. From high-strength amalgams that frame the bit's spine to progressed composites that improve wear resistance, each component is carefully chosen and built to perform beneath the most requesting conditions. As the oil and gas industry proceeds to thrust the boundaries of investigation, the continuous improvement of modern materials and inventive plans will play a significant part in moving forward penetrating proficiency and reliability.

For oil and gas companies, coal mining operations, and penetrating benefit suppliers looking to optimize their boring execution, contributing in high-quality Seven Edge Wing Oil Penetrating Penetrate Bits is fundamental. Shaanxi Hainaisen Petroleum Innovation Co., Ltd. specializes in the inquire about, advancement, and generation of progressed penetrating instruments, counting state-of-the-art Seven Edge Wing Oil Boring Bore Bits. Our items are planned to meet the requesting prerequisites of medium to huge oil benefit companies, advertising uncommon solidness, execution, and value.

With our broad encounter in the industry and commitment to development, we can give custom-made arrangements to meet your particular penetrating needs. Whether you're handling challenging arrangements in oil and gas investigation, conducting geographical studies, or locks in in water well boring, our Seven Edge Wing Oil Penetrating Penetrate Bits are built to excel.

To learn more almost how our progressed penetrate bits can improve your boring operations and diminish by and large costs, it would be ideal if you contact our group of specialists. We're prepared to help you in selecting the right apparatuses for your venture and give continuous specialized back to guarantee ideal execution. Reach out to us at hainaisen@hnsdrillbit.com to talk about your boring necessities and find the Hainaisen advantage.

References

1. Smith, J.R., et al. (2022). "Advanced Materials in Modern Oil Drilling Technology." Journal of Petroleum Engineering, 45(3), 234-251.

2. Johnson, A.K. and Lee, M.S. (2021). "Composite Materials for Harsh Environment Drilling Applications." Materials Science and Engineering: A, 789, 139653.

3. Patel, R.D. (2023). "Optimization of PDC Cutter Placement in Seven Blade Wing Drill Bits." SPE Drilling & Completion, 38(2), 156-170.

4. Zhang, Y., et al. (2022). "Thermal Stability of Diamond Composites in Oil Drilling Applications." Diamond and Related Materials, 123, 108795.

5. Brown, T.H. and White, C.L. (2021). "Material Selection Strategies for Variable Formation Drilling." International Journal of Rock Mechanics and Mining Sciences, 142, 104746.

6. Anderson, M.E. (2023). "Wear Mechanisms in Seven Blade Wing Oil Drill Bits: A Comprehensive Review." Wear, 502-503, 204422.

VIEW MORESteel Tooth Bit

VIEW MORESteel Tooth Bit VIEW MOREFour Blade PDC Rock Drill Bit

VIEW MOREFour Blade PDC Rock Drill Bit VIEW MORE3 Blade PDC Arc Angle Drill Bit

VIEW MORE3 Blade PDC Arc Angle Drill Bit VIEW MOREFour Wing Arc Angle PDC Drill Bit

VIEW MOREFour Wing Arc Angle PDC Drill Bit VIEW MOREThree Blade Concave Drill Bit Api For Manganese Coal Mines

VIEW MOREThree Blade Concave Drill Bit Api For Manganese Coal Mines VIEW MOREHard Alloy Scraper Drill Bit

VIEW MOREHard Alloy Scraper Drill Bit VIEW MOREFour Blade Wing High Performance Petroleum Drill Bit

VIEW MOREFour Blade Wing High Performance Petroleum Drill Bit VIEW MOREPetroleum Drilling Equipment PDC

VIEW MOREPetroleum Drilling Equipment PDC