Cutting Structure: Design for Efficient Rock Removal

The cutting structure is perhaps the most vital feature of a drilling bit for oil and gas rig. It determines how effectively the bit can break and remove rock formations during the drilling process. A well-designed cutting structure ensures efficient penetration and consistent performance across various strata.

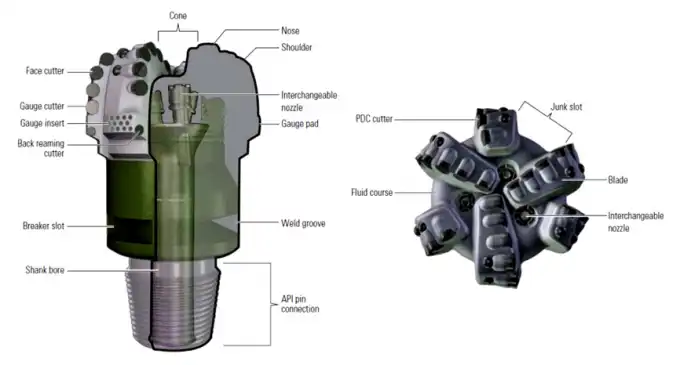

Tooth or Cutter Configuration

The arrangement and geometry of teeth or cutters play a crucial role in the bit's performance. Different configurations are optimized for specific rock types and drilling conditions:

- Roller cone bits: Feature rotating cones with strategically placed teeth

- PDC (Polycrystalline Diamond Compact) bits: Utilize fixed cutters with diamond-impregnated surfaces

- Diamond bits: Employ industrial-grade diamonds embedded in a matrix material

Each type offers unique advantages in terms of cutting efficiency, wear resistance, and suitability for different geological formations.

Blade Design and Placement

For PDC bits, the number, shape, and positioning of blades significantly impact drilling performance. Optimal blade design considers factors such as:

- Rock type and compressive strength

- Required rate of penetration (ROP)

- Stability and vibration control

- Hydraulic efficiency for cuttings removal

Advanced computer modeling and simulation techniques allow manufacturers to fine-tune blade designs for specific drilling applications, enhancing overall bit performance and longevity.

Material Composition: Balancing Durability and Performance

The materials used in constructing a drilling bit for oil and gas rig are critical to its success in challenging downhole environments. The right combination of materials ensures optimal wear resistance, thermal stability, and impact strength.

Cutting Elements

Modern drilling bits utilize advanced materials for their cutting elements, including:

- Tungsten carbide: Offers excellent hardness and wear resistance

- Polycrystalline diamond (PCD): Provides superior abrasion resistance and thermal stability

- Thermally stable polycrystalline (TSP) diamond: Maintains cutting efficiency at high temperatures

These materials are carefully selected and engineered to withstand the extreme conditions encountered during drilling operations, including high temperatures, abrasive formations, and impact loads.

Bit Body Construction

The body of the drilling bit must be robust enough to support the cutting elements while withstanding the rigors of drilling. Common materials include:

- Steel: Used in roller cone bits and some PDC bit designs

- Matrix powder: A composite material consisting of tungsten carbide particles in a metallic binder, offering excellent erosion resistance

- Hybrid designs: Combining steel and matrix materials for optimal performance in specific applications

The choice of body material affects the bit's weight, strength, and ability to dissipate heat generated during drilling. Manufacturers continually research and develop new materials and composites to enhance bit performance and durability across a wide range of drilling conditions.

Hydraulics: Optimizing Fluid Flow for Cooling and Cleaning

Effective hydraulic design is essential for maintaining the performance and longevity of a drilling bit for oil and gas rig. Proper fluid flow management ensures adequate cooling of the bit and efficient removal of rock cuttings from the wellbore.

Nozzle Configuration

The placement and design of hydraulic nozzles significantly impact bit performance:

- Number of nozzles: Varies based on bit type and size

- Nozzle size and orientation: Optimized for specific flow rates and drilling conditions

- Interchangeable nozzles: Allow for field adjustments to suit changing downhole environments

Advanced computational fluid dynamics (CFD) modeling enables manufacturers to optimize nozzle configurations for maximum hydraulic horsepower at the bit face, enhancing cutting removal and cooling efficiency.

Junk Slot Area

The junk slot area refers to the space between blades or cones that allows for the passage of drilling fluid and cuttings. Proper design of this area is crucial for:

- Efficient cuttings evacuation

- Preventing bit balling (accumulation of sticky formations on the bit)

- Maintaining consistent rate of penetration

Manufacturers carefully balance junk slot area with blade or cone coverage to optimize both hydraulic efficiency and cutting structure effectiveness.

Conclusion

Understanding the key features of a drilling bit for oil and gas rig is essential for selecting the right tool for your specific drilling project. By considering the cutting structure, material composition, and hydraulic design, you can ensure optimal performance and efficiency in your drilling operations.

At Shaanxi Hainaisen Petroleum Technology Co., Ltd., we specialize in developing and manufacturing high-quality drilling bits tailored to meet the diverse needs of the oil and gas industry. Our advanced 3,500m² facility, equipped with state-of-the-art 5-axis machining centers and CNC machine tools, allows us to produce drilling bits with superior wear resistance, thermal stability, and customized designs to suit your specific project requirements.

Whether you're involved in offshore exploration, natural gas extraction, or deep-water drilling operations, our team of experts is ready to provide you with integrated technical solutions that will enhance your drilling efficiency and reduce downtime. Don't settle for suboptimal drilling performance – contact us today at postmaster@hnsdrillbit.com to discover how our cutting-edge drilling bits can revolutionize your oil and gas operations.

References

1. Smith, J.R. (2021). Advanced Drilling Technologies for Oil and Gas Exploration. Journal of Petroleum Engineering, 45(2), 112-128.

2. Chen, X., & Wang, L. (2020). Material Innovations in Drilling Bit Design. International Journal of Mining and Mineral Engineering, 11(3), 201-215.

3. Thompson, A.K., & Davis, R.M. (2019). Hydraulic Optimization of PDC Drill Bits: A Comprehensive Review. SPE Drilling & Completion, 34(1), 55-70.

4. Ramirez, C., & Lee, S.H. (2022). Cutting Structure Design for Enhanced Drilling Performance in Challenging Formations. Offshore Technology Conference Proceedings, OTC-32456-MS.

5. Wilson, G.T., & Miller, E.J. (2020). The Impact of Bit Selection on Overall Drilling Efficiency: A Case Study from the Permian Basin. SPE Annual Technical Conference and Exhibition, SPE-201356-MS.

6. Zhang, Y., & Brown, K.L. (2021). Advancements in Drilling Bit Materials: Balancing Durability and Performance. Journal of Materials Science and Engineering, 56(4), 412-428.