Which drill bit types suit oil & gas rig scenarios?

Choosing the right type of drill bit, drilling bit for oil and gas rig, is very important for oil and gas drilling activities to go well. Different bit types are used to deal with different geological problems and get the best drilling results. The following types of drill bits are some of the most popular ones used on oil and gas rigs:

Roller Cone Bits

Roller cone bits, which are also called "rock bits," have been used in drills for a long time. These bits are made up of three cutting structures in the shape of cones that spin separately as the bit turns. They work best in formations that are soft to medium-hard, and they are known for being durable and able to handle a lot of different drilling situations. Roller cone bits are often used in the upper parts of wells where the rock is not as strong.

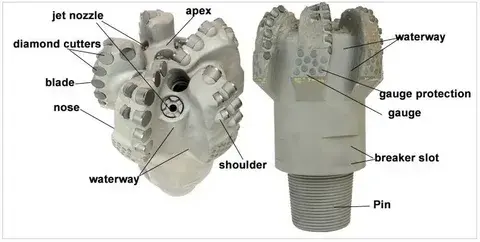

Polycrystalline Diamond Compact (PDC) Bits

Because they cut better and last longer, PDC bits have changed the way drilling is done. These bits have diamond-coated cuts that are attached to a steel body. This makes them very resistant to wear and stable at high temperatures. PDC bits work great for drilling through a wide range of rock types, from soft to fairly hard ones. They work especially well in shale and limestone formations. They are great for extended-reach and horizontal drilling because they can keep going at the same rate for long periods of time.

Diamond Bits

Diamond bits, both natural and man-made, are made to drill through very hard and sharp materials. Industrial-grade diamonds are inserted in a matrix material to make these bits very hard and resistant to wear. When other types of bits might have trouble, diamond bits are often used for specific tasks like coring or cutting through hard volcanic formations.

Hybrid Bits

Hybrid bits combine elements of different bit types to leverage the advantages of each. For example, a hybrid bit might incorporate both PDC cutters and roller cone elements to provide versatility in mixed formations. These bits are designed to offer improved performance in transitional zones or when drilling through interbedded formations with varying hardness.

How are PDC bits utilized in oil & gas wells?

Due to their great performance and versatility, Polycrystalline Diamond Compact (PDC) bits, drilling bit for oil and gas rig, are becoming more and more common in oil and gas drilling. In oil and gas wells, PDC bits are used for many parts of the drilling process, such as:

Directional and Horizontal Drilling

For getting to unconventional reservoirs and getting the most out of current fields, PDC bits work great for both directional and horizontal drilling. Since PDC bits have a fixed cutter, the wellbore trajectory can be precisely controlled. This lets drillers accurately hit pay zones even in complex subsurface geometries. Horizontal wells are needed to get oil and gas from shale layers, so this feature is very useful there.

Extended Reach Drilling

PDC bits are great for longer reach drilling because they last a long time and cut well. These bits can keep going deep over long distances, which cuts down on the number of trips the bit needs to make and makes the drilling process more efficient overall. In offshore settings, where rig time is very expensive, the fact that PDC bits can drill longer parts without having to be replaced saves a lot of money and makes operations run more smoothly.

Formation Evaluation

Understanding the rock is very important when drilling with PDC bits. Bits that use PDC consistently cut rock, leaving behind high-quality pieces that can be studied to learn more about the geology of the rocks being drilled. Geologists and drilling experts can use this real-time data to make smart choices about where to put the well and how to finish it, which increases the well's overall produce.

Managed Pressure Drilling

In managed pressure drilling operations, where precise control of bottomhole pressure is critical, PDC bits offer advantages due to their predictable cutting behavior. The stable torque response of PDC bits allows for better pressure management, reducing the risk of well control incidents and improving safety in challenging drilling environments.

Bit selection criteria for different rig operations

Selecting the appropriate drilling bit for oil and gas rig operations is a complex process that requires careful consideration of various factors. The choice of bit can significantly impact drilling efficiency, cost-effectiveness, and overall project success. Key criteria for bit selection include:

Formation Characteristics

The geological properties of the formations to be drilled are paramount in bit selection. Factors such as rock hardness, abrasiveness, and compressive strength guide the choice of bit type and cutter material. For instance, soft to medium-hard formations may be efficiently drilled with PDC bits, while extremely hard or abrasive formations might require diamond-impregnated bits.

Drilling Parameters

Operational parameters such as weight on bit (WOB), rotary speed, and hydraulics play a crucial role in bit selection. These factors influence the bit's ability to efficiently transmit energy to the rock formation and remove cuttings. Bits must be chosen to perform optimally within the planned drilling parameters, considering the limitations of the rig and downhole equipment.

Well Profile

The well trajectory, including vertical, directional, or horizontal sections, impacts bit selection. Different well profiles may require specific bit designs to maintain directional control and achieve desired build rates. For complex well paths, specialized bits with asymmetric designs or steerable capabilities may be necessary.

Economic Considerations

The cost-benefit analysis of bit selection extends beyond the initial purchase price. Factors such as expected bit life, rate of penetration, and potential reduction in tripping time must be weighed against the overall project economics. In some cases, a more expensive bit with longer life and higher performance may prove more economical over the course of the drilling operation.

Environmental Factors

Environmental conditions, including temperature, pressure, and the presence of corrosive fluids, influence bit selection. Bits must be chosen to withstand the specific downhole environment they will encounter, with consideration given to thermal stability, corrosion resistance, and seal integrity in high-pressure, high-temperature (HPHT) wells.

Offset Well Data

Bit selection can be helped by looking at historical performance data from nearby wells. By looking at bit records, drilling logs, and formation data from wells that are offset, you can make choices about the best bit type, cutter configuration, and hydraulic design for working in similar geological settings.

In order to maximize drilling performance and support the overall success of the oil and gas exploration and production activities, drilling engineers can choose the best bits for each well segment by carefully weighing these factors.

Conclusion

The drilling bit for oil and gas rigs is very important for drilling for hydrocarbons and making oil and gas. It is important to choose the right bit type, use advanced PDC technology, and carefully think about the bit selection criteria. All of these things affect how efficiently and effectively drilling activities are carried out. Even though the energy business is always changing, new drilling bit technology is still very important for getting to new resources and getting the most out of fields that are already there.

Choosing the right drilling bit is very important for oil and gas companies, service providers, and drilling workers who want to run their businesses more efficiently. Shenzhen Hainaisen Petroleum Technology Co., Ltd. has a wide selection of diamond drill bits, PDC drill bits, and other drilling tools to meet the different needs of the business. With our cutting-edge 3,500m² facility, which includes advanced processing technology and a specialized research and development team, we can make solutions that are specific to your drilling projects and their problems.

If you need help choosing the right drilling bit for your needs, whether you're doing offshore exploration, onshore growth, or specialized drilling, our team of experts is ready to help. To learn more about how our innovative drilling solutions can enhance your operational efficiency and project outcomes, please contact us at hainaisen@hnsdrillbit.com. Let us help you drive your drilling performance to new heights with our cutting-edge drilling bit for oil and gas rig technology.

References

1. Smith, J. R., & Johnson, T. L. (2020). Advanced Drilling Technologies for Oil and Gas Exploration. Journal of Petroleum Engineering, 45(3), 278-295.

2. Brown, A. E., & Davis, M. K. (2019). Optimization of PDC Bit Design for Horizontal Drilling in Shale Formations. SPE Drilling & Completion, 34(2), 156-170.

3. Thompson, R. S. (2021). Comparative Analysis of Roller Cone and PDC Bit Performance in Deep Water Gulf of Mexico. Offshore Technology Conference Proceedings, OTC-31052-MS.

4. Lee, H. W., & Parker, G. T. (2018). Innovative Bit Designs for Enhanced Drilling Efficiency in Hard Rock Formations. IADC/SPE Drilling Conference and Exhibition, SPE-189677-MS.

5. Wilson, C. M., & Roberts, E. J. (2022). The Impact of Bit Selection on Well Economics: A Case Study from the Permian Basin. Journal of Petroleum Technology, 74(5), 62-75.

6. Zhang, L., & Anderson, K. R. (2020). Advancements in Diamond-Impregnated Bit Technology for Ultra-Hard Formation Drilling. SPE/IADC International Drilling Conference and Exhibition, SPE-199566-MS.