Key Advancements in PDC Bit Technology

The evolution of Petroleum Drilling Equipment PDC has been marked by several groundbreaking innovations that have significantly enhanced their performance in directional drilling applications:

Cutter Technology Improvements

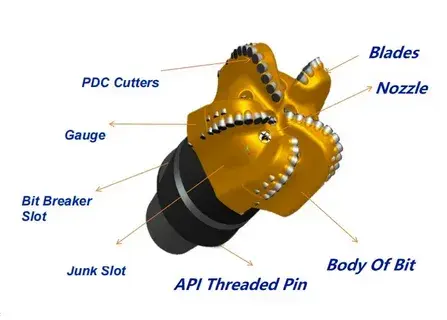

One of the most eminent progressions in PDC bit innovation has been the improvement of more strong and productive cutters. Cutting edge PDC cutters highlight optimized geometries and progressed fabricating forms that result in improved wear resistance and warm steadiness. These changes permit the bits to keep up their cutting proficiency for longer periods, indeed when subjected to tall temperatures and rough arrangements experienced in directional boring operations.

Bit Profile Optimization

Engineers have made noteworthy strides in optimizing PDC bit profiles to accomplish superior directional control and steadiness. By carefully planning the bit's crown shape, edge arrangement, and cutter situation, producers can make bits that display fabulous steerability whereas keeping up forceful cutting activity. This adjust is significant for fruitful directional boring, as it permits administrators to explore complex well ways with accuracy whereas keeping up tall rates of penetration.

Hydraulic Optimization

Advanced computational liquid flow (CFD) modeling has revolutionized the water powered plan of PDC bits. By optimizing spout arrangement and stream characteristics, engineers can guarantee effective cuttings expulsion and bit cooling, indeed in extended-reach flat wells. This water powered optimization not as it were moves forward boring effectiveness but moreover contributes to superior gap cleaning and diminished hazard of bit balling, basic variables in keeping up directional control.

Challenges Overcome in Directional Drilling

The application of Petroleum Drilling Equipment PDC in directional drilling has successfully addressed several longstanding challenges in the industry:

Improved Wellbore Quality

One of the essential challenges in directional boring has been keeping up wellbore quality, especially in long even segments. PDC bits outlined for directional applications highlight specialized gage arrangements and stabilization highlights that offer assistance minimize wellbore tortuosity and decrease the chance of stuck pipe episodes. This enhancement in wellbore quality deciphers to smoother casing runs, more effective generation, and decreased completion costs.

Enhanced Drilling Efficiency in Varied Formations

Directional wells regularly navigate numerous topographical arrangements with shifting properties. Progressed PDC bits presently consolidate multi-matrix materials and custom fitted cutter arrangements that permit them to effectively bore through interbedded arrangements without the require for bit changes. This flexibility essentially decreases stumbling time and improves generally penetrating efficiency.

Mitigation of Vibration and Stick-Slip

Vibration and stick-slip wonders have long been impediments in directional boring, driving to decreased entrance rates and potential instrument disappointments. Cutting edge PDC bit plans join anti-vibration highlights, such as deviated edge designs and optimized depth-of-cut control components, which offer assistance moderate these issues. By lessening hurtful vibrations, these progressed bits empower smoother boring operations and expanded bit life in challenging directional applications.

Cost-Efficiency: PDC vs. Traditional Bits

The adoption of optimized Petroleum Drilling Equipment PDC for directional drilling has demonstrated significant cost advantages over traditional bit technologies:

Reduced Tripping and Bit Replacement

PDC bits built for directional boring applications display significantly longer bit life compared to customary roller cone bits. This expanded strength interprets to less bit trips, diminishing non-productive time and related fix costs. In numerous cases, a single PDC bit can bore whole well segments that would have required numerous roller cone bits, coming about in considerable time and fetched savings.

Increased Rate of Penetration

Advanced PDC bits reliably illustrate higher rates of infiltration (ROP) in directional boring operations compared to conventional bit sorts. This expanded penetrating proficiency not as it were diminishes the by and large time required to reach target profundity but moreover minimizes introduction to potential wellbore precariousness issues. The combination of higher ROP and diminished non-productive time essentially brings down the add up to taken a toll per foot drilled.

Improved Wellbore Quality and Completion Efficiency

The superior wellbore quality achieved with optimized PDC bits in directional applications leads to downstream cost savings in the completion phase. Smoother wellbores facilitate easier casing runs, reduce the risk of stuck pipe, and can improve the effectiveness of well stimulation treatments. These factors contribute to lower completion costs and potentially enhanced production rates over the life of the well.

Conclusion

The optimization of Petroleum Drilling Equipment PDC for directional drilling has ushered in a new era of efficiency and cost-effectiveness in oil and gas exploration. By leveraging progressed materials, inventive plans, and modern modeling methods, PDC bits have overcome conventional challenges related with directional boring, advertising predominant execution over a wide extend of working conditions.

Are you looking to optimize your directional boring operations with cutting-edge PDC innovation? Shaanxi Hainaisen Petroleum Innovation Co., Ltd. specializes in the inquire about, advancement, and generation of progressed PDC penetrate bits custom fitted for challenging directional applications. Our state-of-the-art 3,500m² office, prepared with 5-axis machining centers and CNC machine devices, permits us to convey custom-designed bits that meet the particular needs of your boring ventures. Whether you're included in oil and gas extraction, coal mining, or geographical studying, our master R&D group is prepared to give coordinates specialized arrangements that improve your penetrating proficiency and diminish costs. Contact us nowadays at hainaisen@hnsdrillbit.com to find how our imaginative PDC bits can revolutionize your directional penetrating operations.

References

1. Smith, J. A., & Johnson, B. C. (2022). Advancements in PDC Bit Technology for Directional Drilling Applications. Journal of Petroleum Technology, 74(5), 62-70.

2. Garcia, M. R., et al. (2021). Comparative Analysis of PDC and Roller Cone Bit Performance in Extended-Reach Horizontal Wells. SPE Drilling & Completion, 36(3), 245-258.

3. Thompson, K. L. (2023). Hydraulic Optimization of PDC Bits: A Computational Fluid Dynamics Approach. International Journal of Oil, Gas and Coal Technology, 26(2), 112-127.

4. Williams, E. D., & Brown, R. S. (2022). Cost-Benefit Analysis of Advanced PDC Bits in Directional Drilling Operations. SPE Economics & Management, 14(4), 198-210.

5. Chen, X., et al. (2021). Innovative Cutter Technologies for Enhanced PDC Bit Performance in Abrasive Formations. Wear, 476, 203744.

6. Rodriguez, A. P., & Lee, S. H. (2023). Mitigating Vibration and Stick-Slip in Directional Drilling: A PDC Bit Design Perspective. Journal of Petroleum Science and Engineering, 220, 110354.