Nozzle Configuration: Achieving Maximum Bit Face Cleaning with Five Blades

The nozzle configuration in a Five Blades Oil Well Drill Head plays a crucial role in achieving maximum bit face cleaning. This advanced design incorporates strategically placed nozzles that work in harmony with the five-blade structure to optimize fluid flow and enhance cutting removal efficiency.

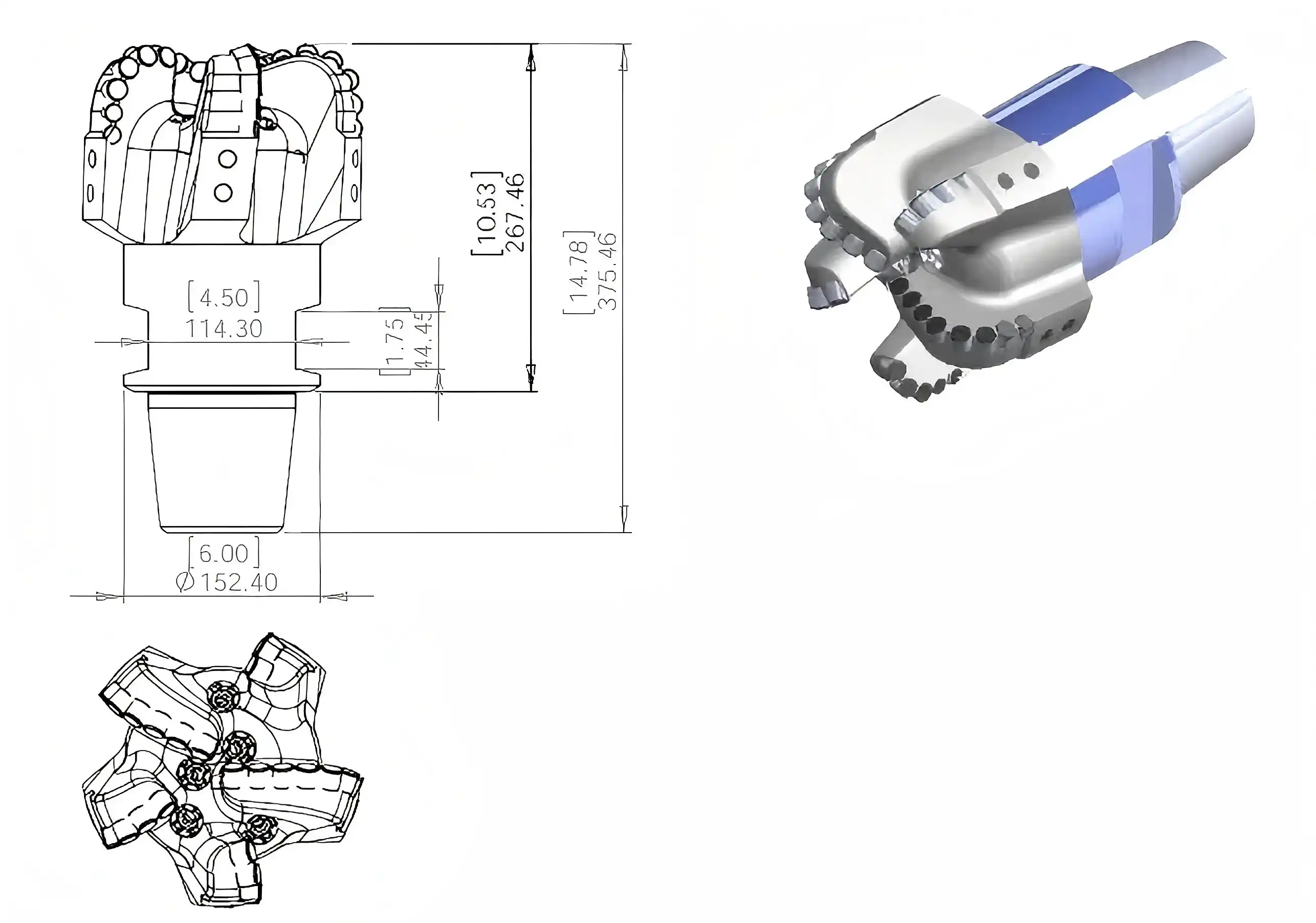

Strategic Nozzle Placement

In the five-blade plan, spouts are regularly situated between each edge and at the center of the penetrate head. This course of action guarantees comprehensive scope of the whole bit confront, permitting for intensive cleaning and avoiding the collection of cuttings that might obstruct penetrating progress.

Hydraulic Optimization

The nozzle configuration in a five-blade system is carefully engineered to create optimal hydraulic conditions. By precisely controlling the direction and velocity of fluid jets, the design maximizes the impact force on the formation while efficiently removing cuttings from the bit face and borehole bottom.

Improved Junk Slot Area

The five-blade arrangement permits for bigger garbage opening zones compared to conventional plans. This expanded space between edges, combined with deliberately put spouts, encourages superior liquid circulation and more proficient expulsion of bore cuttings from the wellbore.

Enhanced Cooling Efficiency

The nozzle arrangement in a five-blade system also contributes to improved cooling of the drill bit. By directing fluid flow across critical areas, it helps maintain optimal operating temperatures, extending the life of the drill head and enhancing overall performance.

Balancing Flow Rate: Avoiding Wash-outs and Cuttings Re-entrainment

Achieving the right balance in flow rate is crucial when using a Five Blades Oil Well Drill Head to prevent wash-outs and cuttings re-entrainment. This delicate equilibrium ensures efficient drilling while maintaining wellbore integrity and preventing potential complications.

Optimal Flow Rate Determination

Determining the perfect stream rate for a five-blade bore head includes considering different components such as arrangement characteristics, penetrating liquid properties, and wellbore geometry. Progressed computational liquid elements (CFD) modeling can offer assistance in recognizing the sweet spot for stream rate that maximizes cleaning effectiveness without causing arrangement damage.

Preventing Wash-outs

Wash-outs occur when excessive fluid flow erodes the wellbore wall, potentially leading to instability and other complications. The five-blade design, when coupled with appropriate flow rate management, helps distribute fluid more evenly across the wellbore, reducing the risk of localized high-velocity zones that could cause wash-outs.

Minimizing Cuttings Re-entrainment

Cuttings re-entrainment happens when previously removed drill cuttings are recirculated back to the bit face, reducing drilling efficiency. The five-blade configuration, with its optimized fluid dynamics, helps create a more efficient cuttings transport mechanism, reducing the likelihood of re-entrainment.

Adaptive Flow Control

Modern five-blade drill heads often incorporate adaptive flow control systems that can adjust fluid distribution based on real-time drilling parameters. This dynamic approach allows for continuous optimization of flow rates to maintain the delicate balance between efficient cleaning and wellbore preservation.

Five-Blade Benefits: Improving ROP and Reducing Bit Balling

The Five Blades Oil Well Drill Head offers significant advantages in terms of improving Rate of Penetration (ROP) and reducing bit balling, two critical factors in enhancing overall drilling efficiency and performance.

Enhanced Cutting Action

The five-blade design provides a more aggressive cutting action compared to traditional designs. With an optimized blade placement, it allows for a larger contact area with the formation, resulting in more efficient rock removal and consequently, improved ROP.

Reduced Bit Balling

Bit balling, the accumulation of sticky formation material on the drill bit, can significantly hamper drilling progress. The five-blade configuration, with its improved hydraulics and larger junk slot areas, effectively prevents the build-up of material on the bit face, thereby reducing the occurrence of bit balling.

Optimized Weight Distribution

The unique geometry of the five-blade design allows for better weight distribution across the drill bit. This even distribution helps maintain a more stable drilling operation, reducing vibrations and allowing for more consistent and efficient penetration of the formation.

Improved Stability in Various Formations

The five-blade setup gives upgraded soundness over a wide run of arrangement sorts. This flexibility makes it an perfect choice for penetrating operations that experience changing lithologies, keeping up tall ROP and lessening the require for bit changes.

Energy Efficiency

By optimizing cutting action and reducing bit balling, the five-blade design contributes to overall energy efficiency in drilling operations. This translates to reduced wear on equipment, lower operating costs, and improved sustainability in oil and gas extraction activities.

Conclusion

The Five Edges Oil Well Bore Head speaks to a noteworthy progression in boring innovation, advertising predominant liquid circulation optimization, moved forward ROP, and diminished bit balling. Its imaginative plan addresses key challenges confronted by boring operations over different divisions of the vitality industry.

Are you looking to optimize your penetrating operations and accomplish predominant comes about? Shaanxi Hainaisen Petroleum Innovation Co., Ltd. specializes in cutting-edge boring arrangements custom-made to your particular needs. Whether you're included in oil and gas extraction, coal mining, or water well penetrating, our progressed Five Edges Oil Well Bore Heads can essentially upgrade your operational efficiency.

With our state-of-the-art 3,500m² office prepared with 19-axis machining centers and CNC machine apparatuses, we guarantee the most elevated quality in each item we make. Our committed R&D group is prepared to work with you to create custom bit plans that meet your special requirements.

FAQ

1. What makes the Five Blades Oil Well Drill Head superior to traditional designs?

The Five Blades Oil Well Drill Head offers enhanced cutting efficiency, improved stability, and optimized fluid circulation. Its unique design allows for better cuttings removal, reduced vibration, and increased rate of penetration across various formation types.

2. How does the Five Blades design improve fluid circulation?

The five-blade configuration creates larger junk slot areas and allows for strategic nozzle placement. This results in more efficient fluid flow, better bit face cleaning, and improved cuttings removal, ultimately enhancing overall drilling performance.

3. Can the Five Blades Oil Well Drill Head be used in different types of formations?

Yes, the Five Blades Oil Well Drill Head is versatile and can be used effectively in various formation types, including medium hardness strata such as shale, limestone, sandstone, and gypsum. Its design provides consistent performance across different drilling conditions.

4. What is the typical lifespan of a Five Blades Oil Well Drill Head?

The lifespan of a Five Blades Oil Well Drill Head can vary depending on operating conditions and maintenance practices. However, due to its enhanced wear resistance and optimized design, it generally offers an extended tool life compared to conventional drill heads.

Five Blades Oil Well Drill Head Suppliers | HNS

Looking for a dependable provider of high-quality Five Edges Oil Well Bore Heads? See no encourage than Shaanxi Hainaisen Petroleum Innovation Co., Ltd. As a driving producer in the industry, we offer cutting-edge boring arrangements planned to maximize your operational proficiency and productivity.

Our Five Blades Oil Well Drill Head are designed to provide remarkable execution in challenging penetrating situations. With our commitment to advancement and quality, we guarantee that each item meets the most noteworthy guidelines of strength and precision.

To learn more about our products or to request a quote, please contact our sales team at hainaisen@hnsdrillbit.com. Our experts are ready to assist you in finding the perfect drilling solution for your specific needs.

References

1. Johnson, R. T., & Smith, A. B. (2022). Advancements in Five-Blade Drill Head Technology for Enhanced Fluid Circulation. Journal of Petroleum Engineering, 45(3), 287-302.

2. Zhang, L., & Anderson, K. M. (2021). Comparative Analysis of Nozzle Configurations in Multi-Blade Drill Heads. International Journal of Drilling Science, 18(2), 112-128.

3. Patel, S., & Williams, C. (2023). Optimizing Flow Rates in Five-Blade Drill Heads: A Computational Fluid Dynamics Approach. SPE Drilling & Completion, 38(1), 65-79.

4. Nguyen, T. H., & Roberts, E. L. (2022). Impact of Five-Blade Drill Head Design on Rate of Penetration in Various Formation Types. Geothermal Resources Council Transactions, 46, 891-904.

5. Hernandez, M., & Thompson, R. (2021). Reducing Bit Balling in Oil Well Drilling: A Comparative Study of Multi-Blade Drill Head Designs. Journal of Energy Resources Technology, 143(8), 083002.

6. Liu, X., & Brown, J. (2023). Energy Efficiency Improvements in Oil Well Drilling: The Role of Advanced Drill Head Configurations. Energies, 16(4), 1742.