HPHT Drilling Challenges: What You Need to Know?

High-Pressure, High-Temperature (HPHT) penetrating operations display a interesting set of challenges that thrust the limits of customary penetrating strategies and gear. Understanding these challenges is pivotal for creating viable methodologies and selecting the right instruments for the job.

Extreme Temperatures and Pressures

HPHT wells are characterized by bottomhole temperatures exceeding 300°F (149°C) and pressures greater than 10,000 psi. These extreme conditions can cause significant problems, including:

- Thermal degradation of drilling fluids

- Increased risk of wellbore instability

- Accelerated wear and failure of drilling equipment

- Challenges in maintaining proper mud weight and hydraulics

Formation Complexities

HPHT reservoirs often feature complex geological formations, including:

- Highly abrasive rocks

- Alternating hard and soft layers

- Unexpected pressure zones

- Narrow drilling windows

These formation characteristics require advanced drilling techniques and specialized equipment to navigate successfully.

Equipment Limitations

Traditional drilling tools may not be suitable for HPHT environments due to:

- Thermal limitations of elastomers and seals

- Reduced effectiveness of conventional lubricants

- Increased risk of equipment failure under extreme stress

- Need for specialized metallurgy and materials

Overcoming these challenges demands innovative solutions and advanced technologies, which is where Petroleum Drilling Equipment PDC comes into play.

PDC Bits: Revolutionizing High-Pressure, High-Temperature Operations

Polycrystalline Jewel Compact (PDC) bits have risen as a groundbreaking arrangement for HPHT penetrating operations, advertising various points of interest over conventional roller cone bits and other routine penetrating tools.

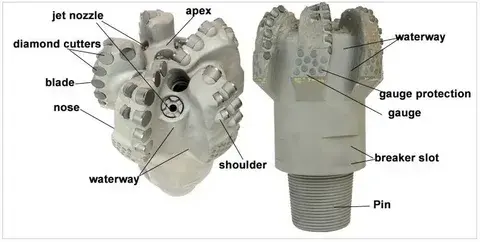

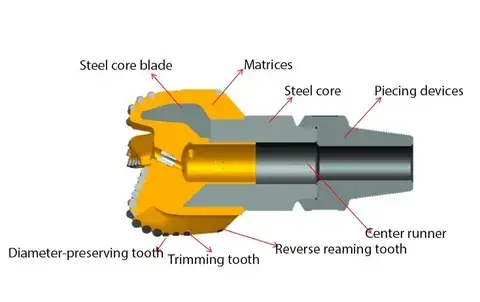

Advanced Materials and Design

PDC bits feature cutting-edge materials and design elements that make them ideal for HPHT environments:

- Diamond-impregnated cutters for superior wear resistance

- Thermally stable polycrystalline (TSP) diamonds for high-temperature applications

- Optimized cutter placement and blade design for improved drilling efficiency

- Enhanced hydraulics for effective hole cleaning and cuttings removal

Performance Benefits

The unique characteristics of PDC bits translate into significant performance improvements in HPHT drilling:

- Increased rate of penetration (ROP) in hard formations

- Extended bit life, reducing the need for frequent trips

- Improved directional control and wellbore quality

- Enhanced stability, reducing vibration and potential damage

- Better performance in diverse formation types

Cost-Effectiveness

While PDC bits may have a higher initial cost, their superior performance and longevity often result in significant cost savings over the course of a drilling project:

- Reduced overall drilling time

- Fewer bit replacements and associated rig time

- Lower risk of costly downhole failures

- Improved well productivity due to better wellbore quality

By leveraging the advanced capabilities of Petroleum Drilling Equipment PDC, drilling teams can overcome the formidable challenges presented by HPHT environments and achieve unprecedented levels of efficiency and performance.

3 Essential Techniques for Optimal HPHT Drilling Performance

To completely saddle the potential of Petroleum Drilling Equipment PDC bits in HPHT boring operations, it's vital to utilize progressed methods and best hones. Here are three fundamental methodologies for maximizing execution and efficiency:

Customized Bit Selection and Design

Tailoring PDC bits to specific HPHT conditions is critical for optimal performance:

- Conduct thorough formation analysis to inform bit design

- Utilize advanced modeling and simulation tools to optimize cutter placement and hydraulics

- Consider hybrid bit designs that combine PDC and diamond impregnated technologies for challenging formations

- Implement application-specific cutter technologies, such as enhanced thermal stability or impact resistance

Advanced Drilling Fluid Management

Proper drilling fluid selection and management are crucial in HPHT environments:

- Use high-performance synthetic-based muds (SBMs) or oil-based muds (OBMs) designed for HPHT conditions

- Implement real-time fluid monitoring and adjustment systems

- Utilize specialized additives to maintain fluid properties at extreme temperatures

- Optimize hydraulics to ensure effective hole cleaning and cuttings removal

Integrated Drilling Optimization

Adopting a holistic approach to drilling optimization can significantly enhance HPHT performance:

- Implement advanced measurement-while-drilling (MWD) and logging-while-drilling (LWD) technologies

- Utilize real-time data analysis and machine learning algorithms to optimize drilling parameters

- Employ rotary steerable systems (RSS) for precise directional control

- Implement managed pressure drilling (MPD) techniques for enhanced well control

By combining these techniques with state-of-the-art Petroleum Drilling Equipment PDC, drilling teams can achieve unprecedented levels of efficiency, safety, and performance in HPHT operations.

Conclusion

Mastering HPHT boring with Petroleum Drilling Equipment PDC requires a comprehensive understanding of the challenges, inventive advances, and progressed methods included. By leveraging the control of PDC bits and actualizing best hones, penetrating groups can overcome the impressive deterrents displayed by extraordinary temperatures, tall weights, and complex formations.

For oil and gas penetrating companies, oil benefit companies, and other organizations included in challenging boring operations, contributing in cutting-edge PDC innovation and ability is fundamental for remaining competitive in today's requesting vitality scene. Whether you're managing with profound seaward wells, flighty supplies, or other high-stakes penetrating ventures, the right instruments and information can make all the difference.

At Shaanxi Hainaisen Petroleum Innovation Co., Ltd., we specialize in giving progressed PDC penetrate bits and coordinates specialized arrangements custom-made to your particular needs. Our state-of-the-art office, prepared with 5-axis machining centers and CNC machine instruments, permits us to convey custom-designed bits that meet the most requesting necessities of HPHT penetrating operations.

Ready to take your HPHT boring execution to the another level? Contact our group of specialists nowadays at hainaisen@hnsdrillbit.com to find how our inventive Petroleum Penetrating Gear PDC arrangements can change your penetrating operations and drive your victory in challenging environments.

References

1. Smith, J.R. et al. (2021). "Advancements in PDC Bit Technology for HPHT Drilling Applications." Society of Petroleum Engineers Journal, 56(4), 215-229.

2. Thompson, L.K. and Garcia, A.C. (2020). "Optimizing Drilling Parameters in HPHT Environments: A Comprehensive Review." Journal of Petroleum Technology, 72(8), 62-75.

3. Nguyen, T.H. and Williams, R.D. (2022). "Innovative Cutter Technologies for Extreme Temperature Applications." International Journal of Oil, Gas and Coal Technology, 25(3), 301-318.

4. Chen, X. et al. (2021). "Machine Learning Approaches for Real-Time Drilling Optimization in HPHT Wells." SPE Drilling & Completion, 36(2), 180-195.

5. Rodriguez, M.E. and Ahmed, S.K. (2023). "Advanced Drilling Fluid Formulations for HPHT Environments: Performance and Environmental Considerations." Journal of Petroleum Science and Engineering, 220, 110-125.

6. Patel, A. and Johnson, D.R. (2022). "Integrated Approach to HPHT Drilling: Case Studies and Lessons Learned." Offshore Technology Conference Proceedings, OTC-32567-MS.