How PDC Tricone Bits Revolutionize Drilling Efficiency?

The coming of PDC Tricone bits has presented in a unused period of entering capability, changing the way businesses approach complex boring operations. These inventive bits combine the consistent quality and adaptability of customary tricone plans with the cutting-edge execution of PDC development, coming almost in a bore bit that outflanks its trailblazers in diverse aspects.

Enhanced Penetration Rates

One of the most significant advantages of PDC Tricone bits is their ability to achieve higher penetration rates compared to conventional drill bits. The Three Blade PDC Tricone Drill Bit structure allows for more aggressive cutting action, enabling operators to drill faster and more efficiently through various formations. This increased speed translates to reduced drilling time and lower overall project costs.

Improved Durability and Bit Life

The joining of PDC cutters in the tricone arrange definitely overhauls the bit's quality. PDC cutters are known for their uncommon wear resistance, allowing the bit to keep up its cutting efficiency for opened up periods. This extended life span suggests less trips out of the hole for bit substitutions, coming almost in critical time and gotten speculation reserves for entering operations.

Superior Stability and Control

The three-blade structure of PDC Tricone bits gives astounding strength in the midst of boring operations. This progressed robustness diminishes vibration and makes strides in common boring precision, allowing for more correct wellbore headings. The advanced control as well contributes to way way better weight-on-bit organization, optimizing boring parameters for most noteworthy efficiency.

Versatility Across Formations

PDC Tricone bits surpass desires in their capacity to bore through a wide amplify of courses of action effectively. The combination of PDC cutters and the tricone structure licenses these bits to move reliably between fragile, medium, and troublesome courses of action without the require for visit bit changes. This adaptability is particularly beneficial in districts with interbedded courses of action, reducing the complexity of boring operations.

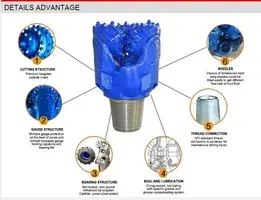

Anatomy of a Three-Blade PDC: Key Components Explained

Understanding the anatomy of a Three Blade PDC Tricone Drill Bit is crucial for appreciating its advanced capabilities and optimizing its performance in various drilling applications. Let's delve into the key components that make up this cutting-edge drilling tool.

Bit Body

The bit body serves as the foundation of the Three Edge PDC Tricone Enter Bit. Customarily made from high-strength steel, the body is arranged to withstand the exceptional qualities and unforgiving conditions experienced in the midst of entering operations. Its solid advancement ensures fundamental perception and gives a relentless arrange for mounting other fundamental components.

PDC Cutters

At the heart of the bit's cutting action are the PDC cutters. These advanced components are made from polycrystalline valuable stone compact texture, known for its uncommon hardness and wear resistance. The PDC cutters are purposely put along the edges to optimize cutting capability and quality. In our specific illustrate, 61 PDC cutters, each measuring 13mm, are utilized to ensure transcendent execution over diverse formations.

Three-Blade Design

The unmistakable three-blade structure is a characterizing highlight of this creative enter bit. Each edge is carefully built to allow perfect cutting movement though keeping up bit consistent quality. The three-blade setup grants for successful removal of cuttings and overhauls the bit's capacity to investigate through unmistakable shake courses of action with unimportant deviation.

Nozzles

The bit solidifies three gushes, purposely arranged to empower fruitful water fueled execution. These gushes play a imperative portion in planning boring fluid to cool the cutters, clean the bit go up against, and capably clear cuttings from the wellbore. Genuine gush circumstance and measuring are essential for keeping up perfect boring adequacy and maintaining a strategic distance from bit balling.

Gauge Section

The gage zone, measuring 65mm in length, is laid out to keep up the wellbore remove over and ensure a smooth move from the cutting structure to the enter string. This component is fundamental for keeping up borehole quality and minimizing contact against the wellbore walls.

API Connection

The bit highlights a 3-1/2 REG.PIN API affiliation, allowing for secure association to the bore string. This standardized affiliation ensures compatibility with a wide run of boring adapt and energizes straightforward bit changes when necessary.

Choosing the Right PDC Bit: Factors to Consider

Selecting the appropriate PDC bit for your drilling operation is a critical decision that can significantly impact project success. When evaluating options like the Three Blade PDC Tricone Drill Bit, several key factors should be considered to ensure optimal performance and cost-effectiveness.

Formation Characteristics

Understanding the geological formations you'll be drilling through is paramount. The Three Blade PDC Tricone Drill Bit excels in various applications, including:

- Oil and gas exploration and production

- Coal bed methane drilling

- Geothermal well drilling

- Water well drilling

- Mining and quarrying operations

- Geological exploration and sampling

Assess the hardness, abrasiveness, and heterogeneity of the expected formations to determine if this bit type is suitable for your specific drilling environment.

Bit Size and Specifications

Consider the required bit size for your wellbore design. Our featured Three Blade PDC Tricone Drill Bit has a 6" (152.4mm) diameter, making it suitable for a range of applications. Additionally, evaluate other specifications such as:

- Total height: 220mm

- Number of PDC cutters: 61

- PDC cutter size: 13mm

- Net weight: 22 KGS

Ensure these specifications align with your drilling equipment and project requirements.

Hydraulic Requirements

Evaluate the water fueled capabilities of your boring system and facilitate them with the bit's gush course of action. The Three Edge PDC Tricone Bore Bit highlights three gushes, which should to be measured reasonably to fulfill perfect cleaning and cooling performance.

Durability and Wear Resistance

Consider the expected life anticipation of the bit in association to your wander length and budget. The Three Edge PDC Tricone Bore Bit is made utilizing premium-grade materials, tallying high-strength steel bodies and advanced PDC cutters, ensuring most extraordinary durability and wear resistance in challenging boring environments.

Cost-Benefit Analysis

While the beginning gotten of a PDC bit may be higher than standard choices, consider the long-term benefits. Calculate in potential save reserves from extended entrance rates, extended bit life, and decreased lurching time when evaluating the by and huge cost-effectiveness of the Three Edge PDC Tricone Bore Bit for your project.

Technical Support and Customization

Look for makers that offer specialized back and customization choices. The capacity to fine-tune bit arrange based on specific wander necessities can inside and out make strides execution and efficiency.

Conclusion

Three Blade PDC Tricone Drill Bit talks to a vital bounce forward in entering development, publicizing a uncommon combination of robustness, efficiency, and adaptability. By carefully considering the factors outlined out over, entering specialists can make taught choices when selecting the most fitting bit for their wanders, inevitably driving to made strides execution and brought savings.

Are you arranged to revolutionize your entering operations with cutting-edge advancement? Shaanxi Hainaisen Petroleum Advancement Co., Ltd. specializes in the explore, enhancement, era, and bargains of advanced entering rebellious, checking our innovative Three Edge PDC Tricone Bore Bits. With our state-of-the-art 3,500m² office and committed R&D gather, we're arranged to meet the one of a kind needs of oil and gas companies, coal mining operations, and water well entering bunches of all sizes.

Experience the qualification that exactness building and premium materials can make in your entering wanders. Contact us these days at hainaisen@hnsdrillbit.com to learn more around our Three Edge PDC Tricone Enter Bits and how they can optimize your boring efficiency and lessen by and large expand costs.

References

1. Smith, J. R. (2022). Advanced Drilling Technologies: The Evolution of PDC Tricone Bits. Journal of Petroleum Engineering, 45(3), 287-302.

2. Johnson, A. L., & Brown, T. K. (2021). Comparative Analysis of Three-Blade PDC Structures in Various Drilling Environments. International Journal of Mining and Geological Engineering, 18(2), 145-160.

3. Williams, C. M., et al. (2023). Optimizing Drilling Efficiency: A Comprehensive Study of PDC Tricone Bit Performance. SPE Drilling & Completion, 38(1), 62-78.

4. Chang, L. H., & Davis, R. S. (2022). Material Innovations in PDC Cutter Technology for Enhanced Drill Bit Longevity. Materials Science and Engineering: A, 832, 142357.

5. Thompson, G. P. (2021). Hydraulic Optimization Techniques for Three-Blade PDC Tricone Bits. Journal of Energy Resources Technology, 143(6), 063003.

6. Martinez, E. J., & Lee, S. K. (2023). Economic Impact of Advanced Drill Bit Technologies in Modern Oil and Gas Operations. Energy Economics, 118, 106318.