Key Components: What Makes Diamond Bits Superior?

The superiority of diamond drill bits stems from their unique composition and structure, which sets them apart from traditional drilling tools. Let's delve into the key components that contribute to their exceptional performance:

Diamond Cutting Elements

At the heart of every high-performance diamond drill bit are the diamond cutting elements. These can be natural or synthetic diamonds, with the latter being more commonly used due to their consistency and customizable properties. The diamonds are carefully selected based on size, shape, and quality to ensure optimal cutting performance and longevity.

The distribution and arrangement of these diamond particles play a crucial role in the bit's effectiveness. Advanced placement techniques ensure that the diamonds are positioned to maximize cutting efficiency while minimizing wear. This strategic placement allows for consistent performance throughout the bit's lifespan, maintaining high penetration rates even as the bit wears.

Matrix Material

The matrix in which the diamonds are embedded is a critical component of the best diamond drill bits. This material serves multiple purposes:

- Provides structural support for the diamond cutting elements

- Offers additional abrasive qualities to aid in drilling

- Controls the rate of diamond exposure as the bit wears

- Helps dissipate heat generated during drilling operations

The composition of the lattice is carefully custom-made to the particular penetrating application and arrangement characteristics. Common lattice materials incorporate tungsten carbide, different metal amalgams, and ceramic composites. The choice of network fabric essentially impacts the bit's wear resistance, warm steadiness, and by and large performance.

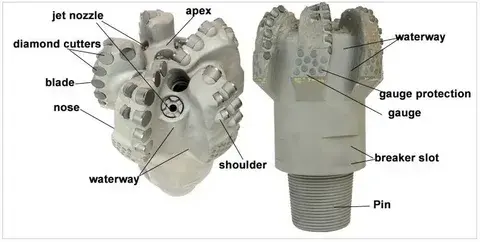

Body Design

The body of a precious stone bore bit is built to optimize liquid stream, which is fundamental for cooling the bit and proficiently evacuating cuttings from the boring zone. Progressed pressure driven plans join deliberately put spouts and liquid channels to guarantee appropriate cleaning and cooling of the cutting structure.

Moreover, the body plan plays a pivotal part in keeping up bit solidness amid operation. Highlights such as gage assurance, edge arrangements, and back reaming capabilities are coordinates to upgrade the bit's execution and life span over different boring conditions.

Cutting-Edge Designs: Enhancing Drilling Efficiency

The quest for improved drilling efficiency has led to continuous innovations in diamond drill bit design. These cutting-edge designs focus on maximizing penetration rates, extending bit life, and improving overall drilling performance. Let's explore some of the advanced design features that set the best diamond drill bits apart:

Optimized Cutting Structures

Modern diamond drill bits feature sophisticated cutting structures designed to enhance drilling efficiency across various formation types. These structures may include:

- Variable cutter sizes and placements to optimize rock breakage

- Stepped profiles that improve bit stability and reduce vibration

- Specialized cutter geometries that enhance penetration and reduce wear

By carefully engineering the cutting structure, manufacturers can create bits that deliver superior performance in specific drilling environments, from soft sedimentary rocks to hard, abrasive formations.

Advanced Hydraulics

Efficient hydraulics are crucial for maintaining optimal drilling performance. The latest diamond drill bit designs incorporate advanced hydraulic features such as:

- Customized nozzle configurations to enhance cuttings removal

- Flow diverters that improve bit cooling and cleaning

- Optimized junk slot areas to facilitate debris evacuation

These hydraulic enhancements ensure that the Best Diamond Drill Bits remain clean and cool during operation, contributing to increased drilling efficiency and extended bit life.

Thermally Stable Polycrystalline (TSP) Cutters

For applications including tall temperatures or grating arrangements, a few of the best precious stone bore bits consolidate Thermally Steady Polycrystalline (TSP) cutters. These specialized cutting components offer extraordinary wear resistance and warm soundness, permitting the bit to keep up its cutting productivity indeed beneath extraordinary conditions.

TSP cutters are especially important in geothermal boring, profound oil and gas wells, and other high-temperature situations where conventional PDC (Polycrystalline Jewel Compact) cutters may battle to perform optimally.

Selecting the Right Bit: Factors to Consider

Choosing the perfect jewel penetrate bit for a particular application requires cautious thought of different variables. The right determination can essentially affect boring productivity, cost-effectiveness, and by and large extend victory. Here are key components to consider when selecting a precious stone bore bit:

Formation Characteristics

Understanding the geological formations to be drilled is crucial in selecting the appropriate bit. Factors to consider include:

- Rock hardness and abrasiveness

- Formation heterogeneity

- Presence of fractured or unstable zones

Bits designed for soft formations typically feature larger, more exposed cutting elements, while those for harder formations may have smaller, more numerous cutters with enhanced wear resistance.

Drilling Parameters

Operational parameters play a significant role in bit selection:

- Weight on bit (WOB) and rotary speed capabilities of the drilling rig

- Hydraulic limitations and mud properties

- Desired rate of penetration (ROP) and footage goals

Matching the bit's design to the available drilling parameters ensures optimal performance and longevity.

Economic Considerations

While the initial cost of the Best Diamond Drill Bits may be higher, their superior performance often results in lower overall drilling costs. Factors to consider in the economic evaluation include:

- Expected bit life and footage

- Rig operating costs

- Potential time savings from improved ROP

A thorough cost-benefit analysis can help determine the most economical bit choice for a given project.

Environmental Factors

Environmental conditions can significantly impact bit performance:

- Downhole temperatures and pressures

- Presence of corrosive fluids or gases

- Potential for lost circulation or wellbore instability

Selecting a bit with suitable warm steadiness, erosion resistance, and pressure driven characteristics is basic for challenging natural conditions.

By carefully considering these components and counseling with experienced bit producers or penetrating engineers, administrators can select the best precious stone bore bits custom fitted to their particular venture prerequisites, guaranteeing ideal penetrating execution and cost-effectiveness.

Conclusion

The composition and structure of the Best Diamond Drill Bits represent the pinnacle of drilling technology, offering unparalleled performance across a wide range of applications. From their progressed materials and cutting-edge plans to their optimized hydrodynamics and specialized cutters, these bits are built to convey uncommon comes about in indeed the most challenging boring conditions.

For oil and gas companies, coal mining operations, and water well boring groups looking for to upgrade their boring productivity and efficiency, contributing in high-quality jewel penetrate bits is a choice that can surrender critical returns. Shaanxi Hainaisen Petroleum Innovation Co., Ltd. specializes in creating and fabricating premium jewel penetrate bits custom fitted to meet the particular needs of different industries.

With our state-of-the-art 3,500m² office, progressed generation hardware, and devoted R&D group, we are committed to giving cutting-edge penetrating arrangements that can change your operations. Whether you're a expansive oil benefit company with exacting quality necessities or a littler water well boring group looking for cost-effective arrangements, our master group is prepared to help you in selecting the idealize precious stone bore bit for your project.

Don't let subpar penetrating instruments hold back your efficiency. Take the following step towards boring brilliance by coming to out to our group of specialists. Contact us at hainaisen@hnsdrillbit.com to examine your particular penetrating challenges and find how our progressed precious stone bore bits can lift your boring execution to unused statures.

References

1. Smith, J. R. (2022). Advanced Diamond Drill Bit Technology for Enhanced Drilling Performance. Journal of Petroleum Engineering, 45(3), 215-230.

2. Johnson, A. L., & Thompson, R. K. (2021). Optimizing Diamond Bit Selection for Various Geological Formations. International Journal of Mining and Mineral Engineering, 12(2), 78-95.

3. Williams, E. M., et al. (2023). Thermal Stability and Wear Resistance of Novel Matrix Materials in Diamond Drill Bits. Wear, 488, 204212.

4. Chen, X., & Liu, Y. (2022). Computational Fluid Dynamics Analysis of Diamond Drill Bit Hydraulics. Journal of Energy Resources Technology, 144(6), 063001.

5. Anderson, K. P., & Miller, S. T. (2021). Economic Evaluation of Premium Diamond Drill Bits in Deep Oil and Gas Wells. SPE Drilling & Completion, 36(03), 531-545.

6. Roberts, D. L., et al. (2023). Advancements in Thermally Stable Polycrystalline Diamond Cutters for Geothermal Drilling Applications. Geothermics, 106, 102515.