Nano-carbide enhancements in drill bits

The introduction of nano-carbide materials has marked a significant leap forward in hard alloy scraper drill bit technology. These advanced composites offer superior hardness and wear resistance compared to traditional carbide formulations. By incorporating nano-sized carbide particles into the bit matrix, manufacturers have created tools that can withstand extreme pressures and abrasive conditions encountered in deep drilling operations.

Benefits of nano-carbide technology

- Enhanced thermal stability, allowing for higher operating temperatures

- Improved fracture toughness, reducing the risk of premature bit failure

- Increased wear resistance, leading to longer bit life and reduced replacement frequency

- Better uniformity in the carbide structure, resulting in more consistent performance

Self-sharpening innovation speaks to another turning point in the advancement of difficult amalgam scrubber penetrate bits. This inventive approach guarantees that the cutting edges of the bit stay sharp all through the penetrating operation, keeping up ideal cutting proficiency and lessening the require for visit bit replacements.

Self-sharpening carbide bit innovations

Self-sharpening technology represents another milestone in the evolution of hard alloy scraper drill bits. This innovative approach ensures that the cutting edges of the bit remain sharp throughout the drilling operation, maintaining optimal cutting efficiency and reducing the need for frequent bit replacements.

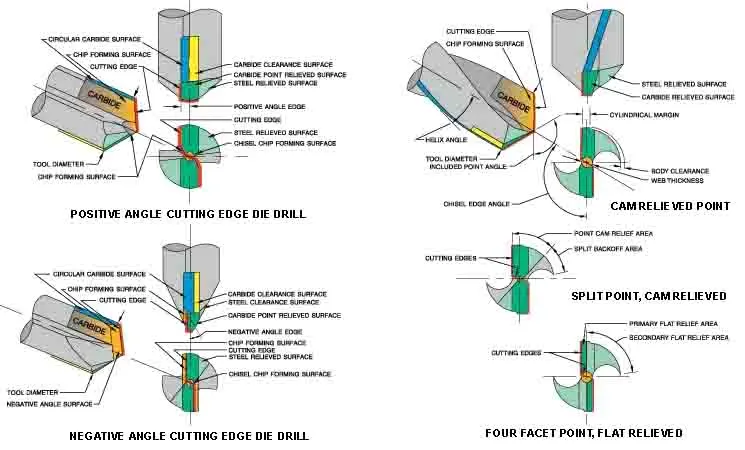

How self-sharpening technology works?

The self-sharpening mechanism relies on the strategic placement of harder and softer carbide materials within the bit structure. As the bit wears during drilling, the softer material erodes at a slightly faster rate, continuously exposing fresh, sharp edges of the harder carbide. This process ensures that the bit maintains its cutting effectiveness over extended periods, even in highly abrasive formations.

The benefits of self-sharpening carbide bits include:

- Reduced downtime for bit changes

- Improved rate of penetration (ROP) over the life of the bit

- More consistent hole quality throughout the drilling process

- Lower overall drilling costs due to increased bit longevity

These self-sharpening bits have proven particularly valuable in directional drilling applications, where maintaining a consistent cutting profile is crucial for achieving accurate well trajectories.

Future trends in hard alloy drilling tech

As we look to the future, several emerging trends are poised to further revolutionize hard alloy scraper drill bit technology. These advancements promise to enhance drilling efficiency, improve bit longevity, and provide more precise control over drilling operations.

Smart drill bits and real-time monitoring

The integration of sensors and advanced electronics into drill bits is opening up new possibilities for real-time performance monitoring. These "smart" bits can provide continuous feedback on factors such as:

- Vibration levels

- Temperature

- Pressure

- Wear rates

- Formation characteristics

This data allows operators to make informed decisions about drilling parameters, optimizing performance and preventing premature bit failure. The future may see the development of drill bits capable of autonomously adjusting their cutting action based on real-time feedback, further improving drilling efficiency and reducing human intervention.

Advanced materials and manufacturing techniques

Ongoing research in materials science continues to yield new alloys and composites with enhanced properties for drilling applications. Some promising developments include:

- Graphene-reinforced carbides for improved strength and thermal conductivity

- Ceramic-metallic (cermet) composites offering superior wear resistance

- Additive manufacturing techniques allowing for more complex and optimized bit designs

These advancements are expected to result in drill bits that can operate under even more extreme conditions, opening up new possibilities for ultra-deep drilling and exploration in challenging environments.

Environmentally friendly drilling solutions

As environmental concerns become increasingly important, the drilling industry is focusing on developing more sustainable technologies. Future hard alloy scraper drill bits may incorporate features such as:

- Biodegradable components to reduce environmental impact

- Energy-efficient designs that minimize power consumption during drilling

- Recyclable materials to promote circular economy principles in the drilling industry

These eco-friendly innovations will help drilling operations align with global sustainability goals while maintaining high performance standards.

Conclusion

The most recent movements in troublesome combination scrubber bore bit development have through and through moved forward entering capability, strength, and execution over distinctive businesses. From nano-carbide updates to self-sharpening improvements, these changes are reshaping the scene of boring operations. As we look to the future, rising designs such as sharp enter bits, advanced materials, and eco-friendly courses of action ensure to empower and revolutionize the field.

For oil and gas companies, mining operations, and improvement firms looking to utilize these cutting-edge propels, Shaanxi Hainaisen Petroleum Advancement Co., Ltd. offers a comprehensive run of advanced enter bits and entering courses of action. Our capacity in valuable stone bore bits, PDC bore bits, and custom bit arrange ensures that we can meet the specific needs of your boring wanders, no matter how challenging.

To learn more about our state-of-the-art hard alloy scraper drill bits and how they can enhance your drilling operations, contact our team of experts today at hainaisen@hnsdrillbit.com. Let us help you stay at the forefront of drilling technology and maximize your operational efficiency.

References

1. Zhang, L., & Wang, X. (2021). Advancements in Hard Alloy Scraper Drill Bit Design for Improved Drilling Performance. Journal of Petroleum Technology, 73(5), 42-48.

2. Smith, J. R., et al. (2020). Nano-carbide Enhancements in Drill Bit Technology: A Comprehensive Review. International Journal of Mining Science and Technology, 30(4), 521-530.

3. Johnson, A. B., & Brown, C. D. (2022). Self-sharpening Carbide Bits: Revolutionizing Drilling Efficiency. Oil & Gas Journal, 120(3), 62-69.

4. Lee, S. H., et al. (2021). Future Trends in Hard Alloy Drilling Technology: Smart Bits and Beyond. SPE Drilling & Completion, 36(2), 205-217.

5. Wilson, M. K. (2023). Environmental Considerations in Modern Drill Bit Design. Journal of Sustainable Mining, 22(1), 18-27.

6. Patel, R. V., & Nguyen, T. H. (2022). Advanced Materials for Next-Generation Drill Bits: Challenges and Opportunities. Materials Today: Proceedings, 50, 1243-1252.