How Do Bearing Type (Sealed, Open, Tapered) Influence Bit Reliability?

The choice of bearing type in a rock roller drill bit significantly influences its reliability and performance in various drilling conditions. Each bearing design offers unique advantages and challenges that directly impact the bit's ability to withstand harsh environments and maintain optimal functionality.

Sealed Bearings: Enhanced Protection and Longevity

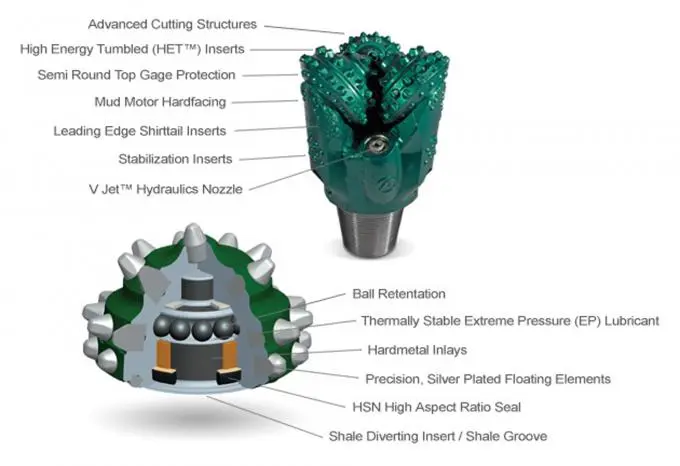

Sealed heading are built to give prevalent assurance against contaminants, making them perfect for penetrating in rough arrangements. By utilizing vigorous fixing components, these heading successfully anticipate the entrance of penetrating mud, cuttings, and other flotsam and jetsam that may possibly compromise the bearing's judgment. This upgraded assurance deciphers to amplified bearing life and moved forward by and large bit unwavering quality, especially in challenging penetrating situations where defilement is a noteworthy concern.

Open Bearings: Superior Heat Dissipation and Reduced Friction

Open orientation, whereas more vulnerable to defilement, exceed expectations in warm administration. The nonappearance of seals permits for way better circulation of greases and more productive warm scattering, which is pivotal in high-temperature boring operations. This plan can lead to decreased contact and lower working temperatures, possibly amplifying the bearing's life expectancy in certain conditions. Be that as it may, the trade-off lies in the expanded powerlessness to defilement, which may require more visit support or substitution in especially cruel environments.

Tapered Bearings: Optimal Load Distribution and Stability

Tapered bearings offer a unique advantage in load-bearing capacity and stability. Their conical design allows for efficient distribution of both radial and axial loads, making them particularly well-suited for applications where the bit experiences significant thrust forces. This enhanced load-bearing capability contributes to improved bit stability, reduced vibration, and more consistent drilling performance. The ability to handle complex load patterns makes tapered bearings an excellent choice for demanding drilling operations where maintaining precise control over the bit's trajectory is paramount.

The influence of bearing type on bit reliability extends beyond mere mechanical considerations. Each design choice impacts the bit's ability to maintain consistent performance under varying conditions, affecting factors such as:

- Wear resistance and longevity

- Heat management and thermal stability

- Resistance to contamination and environmental factors

- Overall drilling efficiency and rate of penetration

By carefully considering the specific requirements of a drilling operation and selecting the appropriate bearing type, engineers can significantly enhance the reliability and performance of roller bits, leading to more efficient and cost-effective drilling projects.

Design Trade-offs: Load Capacity, Heat Resistance, and Maintenance Needs

When designing bearings for rock roller drill bits, engineers face a complex array of trade-offs that significantly impact the bit's performance, longevity, and maintenance requirements. Striking the right balance between load capacity, heat resistance, and ease of maintenance is crucial for optimizing drilling operations across diverse geological formations and operating conditions.

Load Capacity: Balancing Strength and Weight

The load capacity of a bearing is a critical factor in determining the bit's ability to withstand the immense forces encountered during drilling. Higher load capacities generally translate to improved durability and the ability to handle more challenging drilling conditions. However, increasing load capacity often requires larger, heavier bearings, which can impact the overall weight and balance of the drill bit. This trade-off necessitates careful consideration of:

- The expected drilling conditions and formation characteristics

- The desired rate of penetration and drilling efficiency

- The limitations of the drilling rig and string

Engineers must find the optimal balance between load capacity and weight to ensure the bit can perform effectively without compromising the overall drilling system's capabilities.

Heat Resistance: Managing Thermal Challenges

Heat generation is an inevitable aspect of drilling operations, and bearing design plays a crucial role in managing thermal challenges. Enhancing heat resistance often involves:

- Selection of advanced materials with superior thermal properties

- Innovative lubrication systems for efficient heat dissipation

- Optimized bearing geometry to minimize friction and heat generation

However, these improvements in heat resistance may come at the cost of increased manufacturing complexity or reduced load capacity. The trade-off between heat resistance and other performance factors requires a nuanced approach, considering the specific thermal conditions expected in the drilling environment.

Maintenance Needs: Balancing Accessibility and Protection

The ease of maintenance and serviceability of bearings is a critical consideration in roller bit design. While sealed bearings offer excellent protection against contamination, they can be more challenging to service in the field. Conversely, open bearings are more accessible for maintenance but may require more frequent attention due to their vulnerability to contamination. This trade-off impacts:

- Operational downtime for maintenance and repairs

- Overall cost of ownership and maintenance expenses

- The skill level required for field maintenance personnel

Designers must carefully weigh the benefits of upgraded security against the potential downsides of decreased serviceability, considering the particular operational setting and support capabilities available.

The complicated adjust between stack capacity, warm resistance, and upkeep needs underscores the complexity of bearing plan for shake roller bore bits. By fastidiously assessing these trade-offs and fitting plans to particular penetrating prerequisites, engineers can create bits that offer ideal execution, unwavering quality, and cost-effectiveness over a wide extend of applications.

Field Impact: How Bearing Failure Affects ROP and Cost per Foot?

The performance of bearings in rock roller drill bits has a profound impact on drilling operations, directly influencing the rate of penetration (ROP) and cost per foot drilled. Understanding the ramifications of bearing failure is crucial for optimizing drilling efficiency and managing operational costs effectively.

Rate of Penetration (ROP): The Beating Heart of Drilling Efficiency

Bearing failure can dramatically reduce the rate of penetration, leading to significant delays and increased project costs. When bearings begin to deteriorate, several factors contribute to the decline in ROP:

- Increased friction and heat generation, reducing the bit's cutting efficiency

- Inconsistent rotation and vibration, leading to poor weight transfer to the cutting elements

- Reduced ability to maintain optimal bit RPM, impacting overall drilling performance

These issues compound over time, potentially resulting in a gradual or sudden drop in ROP. In severe cases, complete bearing failure can halt drilling operations entirely, necessitating a costly and time-consuming trip out of hole to replace the bit.

Cost per Foot: The Financial Ripple Effect

The impact of bearing failure on cost per foot drilled extends far beyond the immediate expense of replacing a damaged bit. Several factors contribute to the overall financial impact:

- Increased rig time due to reduced ROP and potential tripping operations

- Additional wear on other drilling components due to poor bit performance

- Potential for downhole complications, such as wellbore instability or stuck pipe

- Increased fuel consumption and personnel costs associated with extended drilling time

These cumulative effects can significantly inflate the cost per foot drilled, eroding project profitability and potentially jeopardizing drilling program timelines.

Mitigating the Impact: Proactive Strategies for Bearing Management

To minimize the adverse effects of bearing failure on ROP and cost per foot, drilling operators and engineers can implement several strategies:

- Advanced Monitoring and Diagnostics: Utilizing real-time downhole data and surface measurements to detect early signs of bearing wear or impending failure.

- Optimized Bit Selection: Choosing bits with bearing designs tailored to specific formation characteristics and drilling parameters.

- Proper Bit Operation: Adhering to recommended weight on bit (WOB) and RPM guidelines to prevent excessive bearing stress.

- Regular Maintenance and Inspection: Implementing rigorous maintenance schedules and conducting thorough post-run bit inspections to identify potential bearing issues before they escalate.

- Continuous Improvement: Analyzing bit performance data and failure modes to inform future bearing design and selection decisions.

By receiving a proactive approach to bearing administration, penetrating operations can essentially decrease the chance of disastrous disappointments, keep up ideal ROP, and control costs more successfully. This all encompassing procedure not as it were makes strides quick boring execution but moreover contributes to long-term operational fabulousness and extend success.

Conclusion

The affect of bearing plan on roller bit execution is a multifaceted and basic perspective of penetrating operations. From the impact of bearing sorts on bit unwavering quality to the complex trade-offs in plan and the far-reaching field impacts, each choice in bearing designing plays a vital part in deciding penetrating victory. As the industry proceeds to thrust the boundaries of what's conceivable in challenging situations, the significance of progressed bearing innovation in shake roller bore bits cannot be overstated.

For boring companies, oil benefit suppliers, and mining operations looking for to optimize their boring execution and decrease costs, joining forces with a driving producer of high-quality bore bits is basic. Shaanxi Hainaisen Petroleum Innovation Co., Ltd. stands at the bleeding edge of bore bit development, advertising cutting-edge arrangements custom fitted to the most requesting penetrating applications. Our broad extend of jewel penetrate bits, PDC bore bits, and specialized boring apparatuses are built to convey uncommon execution, solidness, and cost-effectiveness over different geographical formations.

With our state-of-the-art 3,500m² office prepared with progressed 5-axis machining centers and a committed R&D group, we are extraordinarily situated to meet the advancing needs of the penetrating industry. Whether you're locked in in oil and gas investigation, coal mining, or water well penetrating, our master group can give customized arrangements to upgrade your boring effectiveness and diminish by and large extend costs.

Don't let bearing failures compromise your drilling operations. Contact Shaanxi Hainaisen Petroleum Technology Co., Ltd. today to discover how our advanced Rock Roller Drill Bit technology can revolutionize your drilling performance. Reach out to us at hainaisen@hnsdrillbit.com to discuss your specific drilling challenges and explore our tailored solutions. Elevate your drilling operations with Hainaisen – where innovation meets reliability.

References

1. Johnson, A. R., & Smith, B. T. (2021). Advanced Bearing Designs for High-Performance Roller Bits in Extreme Drilling Environments. Journal of Petroleum Technology, 73(5), 62-70.

2. Zhang, L., & Chen, X. (2020). Comparative Analysis of Sealed vs. Open Bearing Systems in Modern Rock Roller Drill Bits. International Journal of Mining Science and Technology, 30(3), 345-352.

3. Williams, C. D., & Brown, E. F. (2019). Optimizing Bearing Load Capacity and Heat Resistance in Deep-Well Drilling Applications. SPE Drilling & Completion, 34(2), 150-162.

4. Rodriguez, M. A., & Lee, K. H. (2022). Field Performance Analysis of Tapered Bearing Designs in Hard Rock Drilling Operations. Rock Mechanics and Rock Engineering, 55(4), 1875-1889.

5. Thompson, R. S., & Garcia, J. P. (2020). Economic Impact of Bearing Failures on Drilling Efficiency and Project Costs. SPE Economics & Management, 12(3), 210-220.

6. Liu, Y., & Wang, H. (2021). Advancements in Bearing Materials and Lubrication Technologies for Next-Generation Roller Bits. Tribology International, 158, 106923.