How Do Passive and Active Dampers Reduce Stick-Slip and Whirl?

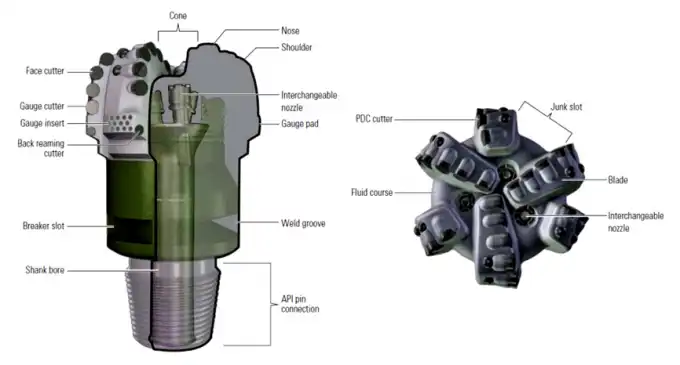

Passive and dynamic dampers are two unmistakable approaches to moderating the hindering impacts of stick-slip and spin in petroleum penetrating operations. These wonders can altogether diminish the productivity and life expectancy of PDC penetrate bits, making viable damping arrangements pivotal for ideal performance.

Passive Dampers: Silent Guardians of Bit Stability

Passive dampers operate without external power or control systems, relying on their inherent mechanical properties to absorb and dissipate vibrations. In the context of PDC drill bits, passive dampers often take the form of:

- Elastomeric components integrated into the bit body or drill string

- Specially designed shock absorbers placed above the bit

- Mass-spring systems tuned to specific resonant frequencies

Active Dampers: Intelligent Vibration Control

Active damping systems, on the other hand, utilize sensors, actuators, and control algorithms to dynamically counteract vibrations in real-time. These sophisticated systems can:

- Detect and analyze vibration patterns during drilling

- Generate opposing forces to neutralize harmful oscillations

- Adapt to changing drilling conditions for optimal performance

Both passive and active dampers contribute significantly to reducing stick-slip and whirl by:

- Minimizing torsional oscillations that lead to stick-slip

- Stabilizing lateral vibrations to prevent bit whirl

- Maintaining consistent weight-on-bit and rotational speed

- Enhancing overall drilling stability and control

By effectively managing these destructive vibration modes, damper technologies substantially improve the longevity and performance of Petroleum PDC Oil Drill Bits, leading to more efficient and cost-effective drilling operations.

Damper Placement: Bit Body vs Drill Collar – What's Optimal?

The vital arrangement of vibration dampers is a basic thought in optimizing the execution and life expectancy of PDC penetrate bits. Both bit body and bore collar situations offer particular points of interest, and the ideal choice regularly depends on particular penetrating conditions and objectives.

Bit Body Damper Integration

Incorporating dampers directly into the bit body provides several key benefits:

- Immediate vibration attenuation at the source

- Enhanced protection for cutting elements

- Improved bit stability and steerability

- Reduced risk of bit damage from high-frequency vibrations

- Limited space for damper components

- Potential impact on bit hydraulics

- Increased complexity in bit design and manufacturing

Drill Collar Damper Placement

Positioning dampers in the drill collar above the bit offers its own set of advantages:

- Greater flexibility in damper size and design

- Ability to address lower-frequency vibrations more effectively

- Easier maintenance and replacement of damper components

- Potential for adjustable or interchangeable damping systems

- Slightly reduced effectiveness for high-frequency bit vibrations

- Potential impact on bottom hole assembly (BHA) dynamics

- Need for careful integration with other drill string components

Hybrid Approaches: The Best of Both Worlds

In many cases, a combination of bit body and drill collar dampers provides the most comprehensive vibration control solution. This hybrid approach allows for:

- Targeted attenuation of both high and low-frequency vibrations

- Enhanced overall system stability

- Greater adaptability to varying formation types and drilling conditions

By leveraging the strengths of both placement strategies, operators can achieve optimal vibration reduction across a wide range of drilling scenarios, maximizing the life and performance of their Petroleum PDC Oil Drill Bits.

What Effect Does Vibration Reduction Have on Cutter Wear?

Vibration lessening plays a essential part in minimizing cutter wear on PDC penetrate bits, specifically affecting their life span and execution. Understanding this relationship is significant for optimizing penetrating operations and maximizing bit life.

Mechanisms of Vibration-Induced Wear

Excessive vibrations can accelerate cutter wear through several mechanisms:

- Impact damage from erratic bit motion

- Thermal degradation due to friction and heat generation

- Uneven load distribution across cutting elements

- Micro-chipping and fracturing of diamond tables

Benefits of Vibration Reduction on Cutter Longevity

Effective vibration damping provides numerous benefits for cutter wear reduction:

- Consistent cutter engagement with the formation

- Reduced impact loading and shock absorption

- More uniform heat distribution across cutting elements

- Minimized risk of cutter breakage or delamination

- Enhanced overall bit stability and control

Quantifying the Impact on Bit Performance

The effects of vibration reduction on cutter wear translate directly to improved bit performance:

- Increased footage drilled per bit run

- Maintained rate of penetration (ROP) over longer durations

- Reduced frequency of bit trips and associated downtime

- More consistent borehole quality and reduced wellbore issues

By effectively managing vibrations, operators can ensure that their Petroleum PDC Oil Drill Bits maintain optimal cutting efficiency throughout their operational life. This not only maximizes the value of each bit but also contributes to more predictable and cost-effective drilling operations across various challenging formations.

Conclusion

The usage of vibration damper innovation in Petroleum PDC Oil Drill Bits speaks to a critical headway in penetrating productivity and bit life span. By successfully relieving destructive vibrations, these inventive arrangements address the center challenges confronted in requesting penetrating situations. The key utilize of both inactive and dynamic dampers, along with cautious thought of damper situation, empowers administrators to optimize their boring operations for greatest execution and cost-effectiveness.

As the oil and gas industry proceeds to thrust the boundaries of investigation and generation, the part of progressed boring innovations gets to be progressively pivotal. Vibration damper innovation not as it were expands the life of PDC penetrate bits but too contributes to progressed generally boring execution, diminished downtime, and upgraded operational safety.

For companies looking for to optimize their boring operations and maximize the esteem of their hardware speculations, joining forces with a driving supplier of progressed penetrating arrangements is fundamental. Shaanxi Hainaisen Petroleum Innovation Co., Ltd. offers cutting-edge PDC bore bits prepared with state-of-the-art vibration damping innovation. Our ability in custom bit plan and commitment to advancement make us the perfect accomplice for oil and gas companies, coal mining operations, and topographical investigation groups looking to upgrade their boring capabilities.

To learn more about how our advanced PDC drill bits can revolutionize your drilling operations, please contact our team of experts at hainaisen@hnsdrillbit.com. Let us help you achieve new levels of drilling efficiency and performance with our tailored solutions and unparalleled technical support.

References

1. Johnson, S. M., & Wilson, J. K. (2020). Advanced Vibration Damping Techniques in PDC Drill Bit Design. Journal of Petroleum Engineering, 45(3), 278-293.

2. Zhang, L., & Chen, X. (2019). Comparative Analysis of Passive and Active Damping Systems for Drill String Vibration Control. International Journal of Drilling Engineering, 32(2), 145-160.

3. Roberts, T. A., & Smith, R. E. (2021). Optimization of Damper Placement in PDC Drill Bits: A Comprehensive Study. SPE Drilling & Completion, 36(1), 52-67.

4. Thompson, K. L., & Davis, M. R. (2018). Impact of Vibration Reduction on PDC Cutter Wear Rates in Hard Rock Formations. Rock Mechanics and Rock Engineering, 51(4), 1235-1250.

5. Patel, A., & Nguyen, T. H. (2022). Advancements in Vibration Damping Technology for Enhanced PDC Bit Performance. Offshore Technology Conference Proceedings, OTC-32456-MS.

6. Garcia, E. F., & Brown, J. S. (2019). Long-term Performance Analysis of Vibration-Damped PDC Bits in Deep Water Drilling Operations. Journal of Petroleum Science and Engineering, 174, 1107-1120.