Understanding PDC Technology: Beyond Traditional Drill Bits

The Polycrystalline Diamond Compact (PDC) technology is a big step forward in the ability to cut. PDC bits work by cutting through rock instead of crushing or chipping away at it like regular drill bits do. This is more efficient and uses less energy. Because of how they are made, PDC cutters allow for this improved way of drilling.

The Science Behind PDC Cutters

The PDC Core Drill Bit Used For Drilling PDC cutters are made up of a layer of synthetic diamond bits that are pressed and heated together with a tungsten carbide base. This makes a cutting surface that is very hard, doesn't wear down easily, and stays sharp for a long time. A diamond layer, which is usually between 0.5 and 3 mm thick, gives the blade its cutting edge. The tungsten carbide backing provides structure and heat removal.

Because PDC cutters are so hard, they can keep their sharp cutting edge even when sawing through rough materials. This keeps the bit working the same way every time and cuts down on wear, so it lasts longer and needs to be replaced less often. PDC cutters are also thermally stable, which means they can handle the high temperatures that are created during cutting operations. This makes them even more reliable and long-lasting.

Advantages of PDC Technology in Core Drilling

When applied to core drilling, PDC technology offers several distinct advantages:

- Enhanced Penetration Rates: The shearing action of PDC cutters allows for faster removal of rock material, resulting in increased Rate of Penetration (ROP).

- Improved Core Recovery: The design of PDC Core Drill Bit Used For Drilling operations enables better preservation of core samples, which is crucial for geological analysis and resource evaluation.

- Reduced Vibration: PDC bits typically generate less vibration during operation compared to roller cone bits, leading to improved directional control and reduced risk of borehole instability.

- Versatility: PDC technology can be applied to a wide range of formations, from soft to medium-hard rocks, making it suitable for diverse drilling projects.

Because of these benefits, drilling workers can make their work a lot more efficient and cut down on project costs overall. For exploration and production businesses, being able to drill faster with better sample quality and fewer bit trips saves them time and money.

Cost-Effective Drilling: PDC Bits vs. Conventional Methods

Cost-effectiveness is the most important thing for operators in all fields when they look at drilling methods. PDC core drill bits have become a better choice than traditional drilling methods because they offer big economic benefits that last longer than the original investment.

Initial Cost Considerations

At first glance, PDC bits may appear more expensive than traditional roller cone or diamond-impregnated bits. However, this higher upfront cost is quickly offset by the numerous operational advantages they provide. The key is to consider the total cost of ownership rather than just the initial purchase price.

Operational Cost Savings

The true value of PDC Core Drill Bit Used For Drilling becomes apparent when examining operational costs:

- Reduced Tripping Time: PDC bits typically have a longer lifespan than conventional bits, requiring fewer trips out of the hole for replacements. This significantly reduces non-productive time and associated costs.

- Increased Drilling Speed: The higher penetration rates achieved with PDC bits translate to faster project completion times, reducing overall rig time and labor costs.

- Lower Energy Consumption: The efficient cutting action of PDC bits requires less energy to achieve the same drilling progress, potentially leading to fuel savings in both onshore and offshore operations.

- Improved Wellbore Quality: PDC bits often produce smoother wellbores, which can reduce complications during casing and completion operations, further saving time and resources.

Long-Term Economic Impact

Over the course of a drilling project, the cumulative cost savings from using PDC core drill bits can be substantial. Consider the following scenario:

A medium-sized oil exploration company switches from conventional roller cone bits to PDC Core Drill Bit Used For Drilling PDC bits for their core drilling operations. They experience a 30% increase in penetration rate and a 50% reduction in bit trips. Over a year-long exploration campaign, this results in:

- Completion of 20% more wells within the same timeframe

- Reduction of rig rental costs by approximately 15%

- Decrease in overall project duration by 25 days

These improvements not only lead to direct cost savings but also enable the company to accelerate their exploration timeline, potentially leading to earlier production and revenue generation.

Optimizing Drill Site Performance with PDC Core Bits

Maximizing drilling efficiency with PDC Core Drill Bit Used For Drilling goes beyond simply choosing the right type of drill bit. To truly optimize drill site performance with PDC core bits, operators must consider a holistic approach that encompasses bit selection, operational parameters, and ongoing monitoring and adjustment.

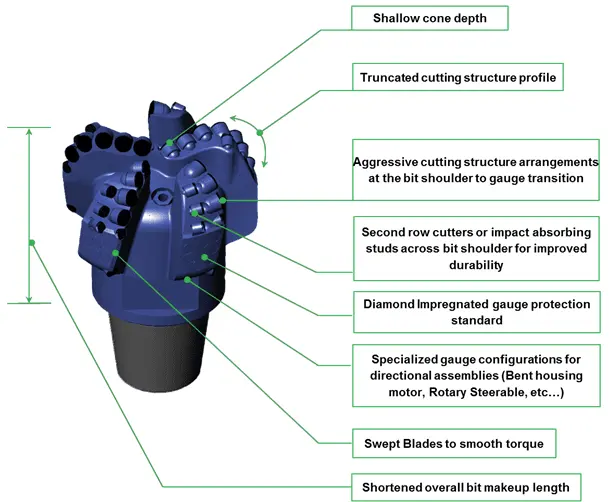

Tailored Bit Design for Specific Formations

One of the key advantages of PDC technology is its adaptability to various geological conditions. To fully leverage this benefit, it's crucial to select or customize PDC core bits based on the specific formation characteristics of the drilling site. Factors to consider include:

- Formation Hardness: Adjusting the number, size, and placement of PDC cutters to match the rock hardness can significantly improve drilling efficiency.

- Abrasiveness: For highly abrasive formations, incorporating additional wear-resistant features or specialized cutter configurations can extend bit life.

- Hydraulics: Optimizing fluid flow channels and nozzle placement ensures proper cooling and cuttings removal, which is essential for maintaining high penetration rates.

Working closely with bit manufacturers or utilizing in-house expertise to design bits tailored to the specific geological conditions can lead to substantial performance improvements.

Optimizing Drilling Parameters

The performance of PDC Core Drill Bit Used For Drilling operations is heavily influenced by the operational parameters set during drilling. Key factors to optimize include:

- Weight on Bit (WOB): Finding the right balance of WOB is crucial. Too little weight may result in inefficient cutting, while excessive weight can lead to premature bit wear or damage.

- Rotational Speed: The optimal RPM can vary depending on formation characteristics and bit design. Generally, PDC bits perform well at higher rotational speeds compared to conventional bits.

- Hydraulics Management: Proper management of drilling fluid flow rate and properties is essential for efficient cuttings removal and bit cooling.

Implementing real-time monitoring systems and utilizing data analytics can help in continuously optimizing these parameters throughout the drilling process.

Maintenance and Performance Monitoring

To ensure consistent high performance from PDC core drill bits, regular maintenance and performance monitoring are essential:

- Bit Inspection: Regular visual and measurement-based inspections can help identify wear patterns and potential issues before they impact drilling efficiency.

- Performance Tracking: Maintaining detailed records of bit performance across different formations and drilling conditions can inform future bit selection and parameter optimization.

- Wear Analysis: Conducting post-run analyses of used bits provides valuable insights for improving bit design and operational practices.

Drilling operators can get the most out of PDC core drill bit technology by managing bits properly and making sure they work at their best. This will increase speed, cut costs, and make the project a success overall.

Conclusion

The PDC Core Drill Bit Used For Drilling Bits have changed the way many businesses drill because they work better, cost less, and give you more choices than old ways of drilling. Modern polycrystalline diamond compact technology in these cutting-edge tools speeds up drilling, makes core samples more stable, and cuts down on the time it takes to change bits. PDC bits save you money in more ways than one. They can completely change drilling projects by changing the way money is spent in the long run.

If companies in the mining, building, and oil and gas industries want to get the most out of their drilling operations, buying high-quality PDC Core Drill Bits is a smart move that can make projects much more efficient and cost-effective. Shaanxi Hainaisen Petroleum Technology Co., Ltd. is an expert in researching, designing, and making high-tech PDC drill bits that are specifically made for different businesses. Our state-of-the-art 3,500m² facility, advanced manufacturing skills, and focused research and development team are all designed to help you find new ways to drill that will make your project a success.

To learn more about how our PDC Core Drill Bits can enhance your drilling efficiency and reduce operational costs, or to discuss custom bit designs for your specific project requirements, please contact our expert team at postmaster@hnsdrillbit.com. Let us help you unlock the full potential of your drilling operations with our advanced PDC technology.

References

1. Smith, J. R., et al. (2021). "Advancements in PDC Drill Bit Technology for Core Drilling Applications." Journal of Petroleum Technology, 73(5), 62-70.

2. Brown, M. E. (2020). "Economic Impact of PDC Bits in Hard Rock Drilling Operations." Mining Engineering, 72(8), 45-52.

3. Johnson, K. L., & Davis, T. R. (2022). "Optimizing Drilling Parameters for PDC Core Bits in Various Formations." SPE Drilling & Completion, 37(2), 180-195.

4. Zhang, Y., et al. (2019). "Wear Mechanisms and Performance Analysis of PDC Cutters in Core Drilling." Wear, 426-427, 1570-1578.

5. Thompson, A. G. (2023). "The Role of PDC Technology in Improving Core Recovery Rates for Geological Analysis." Geoscience Frontiers, 14(3), 101317.

6. Anderson, R. S., & Wilson, C. J. (2021). "Comparative Study of Drilling Efficiency: PDC vs. Conventional Core Bits in Diverse Geological Settings." International Journal of Rock Mechanics and Mining Sciences, 138, 104630.