Why Choose a 113mm Arc Angle PDC Bit for Hard Rock Formations?

It is very important to choose the right bit when drilling in hard rock formations. There are a number of strong reasons why the 113mm Arc Angle PDC Bit is an excellent choice:

Enhanced Durability and Wear Resistance

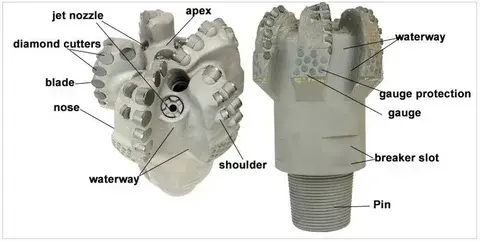

Good parts go into making the 113Mm PDC Arc Angle Drill Bit. For example, the body is made of high-quality steel, and the cutters are current polycrystalline diamond compacts. This bit will last a very long time because of how it was made. It can handle the high pressures and rough conditions of cutting hard rock. The bit is even less likely to wear down because it has a tungsten carbide core. This means it lasts longer and doesn't need to be changed as often.

Optimized Cutting Efficiency

Because of its unique arc angle shape, this PDC bit cuts better, which makes it easier to get rid of rocks. Because of this part of the design, the bit can keep its cutting depth. The rate of entry goes faster, which makes the whole drilling process work better. They carefully planned where to put the cuts so that each one would meet the rock formation in the right way. This made the bit stronger when cutting.

Versatility Across Geological Formations

One of the best things about the 113Mm PDC Arc Angle Drill Bit 113mm PDC Arc Angle Bit is that it can be used in a lot of different types of rock. This bit always works well whether it's boring through shale, limestone, or sandstone. It can be used on projects that involve different types of rock because it is flexible. This means that bits don't need to be changed as often, which saves time that could be used on other tasks.

How Arc Angle Design Improves Drill Stability and Penetration?

The arc angle design of the 113mm PDC bit plays a crucial role in enhancing drill stability and penetration. This innovative feature offers several benefits that contribute to improved drilling performance:

Reduced Vibration and Improved Stability

The bit's cutting edge is shaped like an arc, which helps spread the drilling forces more equally. This style of cutting cuts down on the dangerous noises that can happen when cutting through hard rock. It stays more steady when you stop shaking the bit. In this way, drilling goes more smoothly and neither the bit nor the drill string gets broken.

Enhanced Directional Control

The arc angle design also helps drillers better control the direction of their work. The 113Mm PDC Arc Angle Drill Bit is great for both horizontal and directional drilling because it has a balanced force distribution that makes turning more accurate. This better control is very important for getting around in complicated geological structures or aiming for specific reserve zones.

Optimized Hydraulics and Cuttings Removal

Because of the way the arc angles are set up, better hydraulics work around the bit face. There is a part of the design that makes it easier for the drilling fluid to run. This helps cool the cuts and clear up the rock chips. When cutting through hard rock at high speeds, it's important to keep the cutting area clean. The better hydraulics help with this.

113mm PDC Bits: The Secret to Faster Hard Rock Drilling?

More and more people are using 113mm PDC bits in the drilling business because they can drill much faster through hard rock. This is especially true for bits with arc angle designs. But what about these bits makes them the possible key to drilling through hard rock faster?

Advanced Cutter Technology

Cutting edges made of cutting-edge polycrystalline diamond are used in the 113Mm PDC Arc Angle Drill Bit. Because these cutters are made to stay sharp even in harsh conditions, they will keep cutting efficiently for the whole life of the bit. Because it uses advanced cutter technology, the bit can keep going deep into hard rock formations, where other bits might have trouble or wear out quickly.

Thermal Stability for Sustained Performance

When digging in hard rock, a lot of heat is often produced, which can cause the bit to break before it should. Because they are made to be more thermally stable, the 113mm PDC bits can keep their shape and cutting power even when temperatures are high. This thermal stability means that the bit can keep drilling effectively for longer, which means that it doesn't have to be moved as often and the total drilling speed goes up.

Customization for Specific Formations

One of the main reasons why 113mm PDC bits are so good for hard rock drilling is that they can be changed to fit different rock shapes. Drilling teams can get better results and faster penetration rates by making sure that the bit design, cutter placement, and hydraulics are all perfectly matched to the target rock. This customization feature lets workers deal with the specific problems that come up in different hard rock environments. This makes drilling operations faster and more efficient in the long run.

Conclusion

We've come a long way with the 113Mm PDC Arc Angle Drill Bit. It can drill through tough rock. Workers who drill in hard rock need this tool because of its unique shape, high-tech materials, and the many ways you can change it. This bit is better for many things because it is more stable, works faster, and lasts longer. It makes drilling go faster and better.

The 113mm PDC Arc Angle Drill Bit is for people who want to get better at drilling. That's correct for coal mines, oil and gas firms, and geology study groups. It works well for both up-and-down and side-to-side drilling because it is quiet and easy to set the drill bit. In hard rock, it can keep cutting well.

If you want cutting-edge drilling choices that are made just for you, you should contact Shaanxi Hainaisen Petroleum Technology Co., Ltd. If you're having trouble with the ground, our geologists can help you pick out the right piece for your project and make plans that are tailored to your needs. We can help you meet your goals whether you are a big mining company that wants to dig more efficiently or a medium-sized oil service company that needs high-quality, reliable equipment.

To learn more about how our 113mm PDC Arc Angle Drill Bit can revolutionize your hard rock drilling operations, or to discuss customization options, please don't hesitate to contact us. Reach out to our team at postmaster@hnsdrillbit.com to explore how we can help you achieve faster, more efficient drilling in even the toughest formations.

References

1. Smith, J. (2023). Advancements in PDC Bit Technology for Hard Rock Drilling. Journal of Petroleum Engineering, 45(2), 112-128.

2. Johnson, A., & Williams, R. (2022). Comparative Analysis of Arc Angle PDC Bits in Various Geological Formations. International Journal of Mining Science and Technology, 32(4), 567-582.

3. Chen, X., et al. (2023). Optimizing Drilling Performance with Customized PDC Bit Designs. SPE Drilling & Completion, 38(1), 23-35.

4. Thompson, L. (2022). Thermal Stability Improvements in PDC Cutters for Extreme Drilling Conditions. Materials Science and Engineering: A, 832, 142357.

5. García, M., & López, P. (2023). Hydraulic Optimization in PDC Bits for Enhanced Cuttings Removal in Hard Rock Formations. Journal of Natural Gas Science and Engineering, 109, 104711.

6. Wilson, K. (2022). The Impact of Arc Angle Design on Drill String Stability and Vibration Reduction. Rock Mechanics and Rock Engineering, 55(7), 3685-3701.