What design features allow PDC drill bits to manage high torque and vibration?

PDC drill bits for coal mining applications incorporate several key design features to effectively manage high torque and vibration:

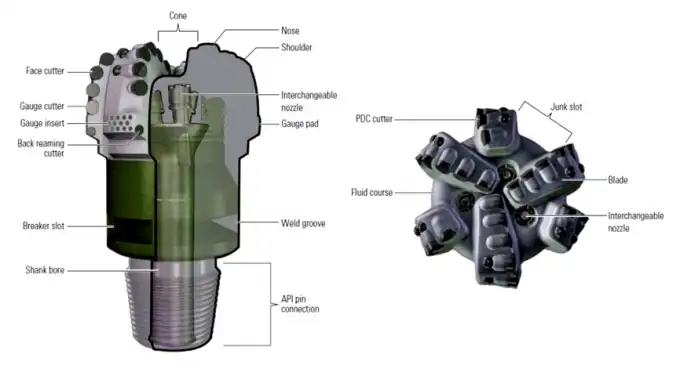

Reinforced Blade Structures

The blade structures of coal mining PDC bits are engineered with enhanced thickness and support. This reinforcement allows the blades to withstand higher torque levels without deformation or failure. The increased structural integrity also contributes to improved vibration resistance by minimizing blade flexing during operation.

Optimized Cutter Placement

Strategic positioning of PDC cutters on the bit face plays a crucial role in managing torque and vibration. By carefully arranging the cutters, engineers can distribute cutting forces more evenly across the bit, reducing the likelihood of sudden torque spikes and minimizing harmful vibrations. This optimization often involves varying cutter sizes, angles, and densities across different regions of the bit.

Balanced Bit Profiles

Coal mining PDC bits feature carefully designed profiles that contribute to their stability during operation. These balanced profiles help to minimize bit whirl and lateral vibrations, which can be particularly problematic in coal formations. By maintaining a more stable drilling trajectory, these bits can better handle the torque generated during the cutting process.

Shock-Absorbing Elements

Many advanced Coal Mining PDC Drill Bits incorporate shock-absorbing components within their structure. These elements, which may include specialized materials or mechanical designs, help to dampen vibrations before they can propagate through the entire drilling assembly. By reducing the transmission of harmful vibrations, these features protect both the bit and the drilling equipment from excessive wear and potential damage.

Techniques for reducing vibration and torque stress in coal mining PDC bits

Several techniques are employed to mitigate vibration and torque stress in PDC bits used for coal mining:

Anti-Whirl Technology

Anti-whirl designs are incorporated into many coal mining PDC bits to combat the tendency of the bit to rotate eccentrically. This technology typically involves asymmetric cutter layouts and specialized gauge pad configurations. By reducing bit whirl, these designs help to minimize harmful vibrations and distribute torque more evenly across the bit face.

Variable Cutter Sizes and Geometries

Utilizing a range of cutter sizes and geometries across the bit face can significantly reduce vibration and torque stress. Larger cutters may be used in the center of the bit for increased stability, while smaller, more aggressive cutters can be placed towards the outer regions to maintain cutting efficiency. This variation helps to create a more balanced cutting action, reducing the likelihood of sudden torque spikes.

Specialized Gauge Pad Designs

The gauge pads of Coal Mining PDC Drill Bits are engineered to provide stability and reduce lateral vibrations. These pads may feature spiral configurations or stepped designs that help to maintain consistent contact with the borehole wall. By doing so, they contribute to smoother rotation and more effective torque management.

Hydraulic Optimization

Proper hydraulic design is crucial for managing vibration and torque in coal mining applications. Optimized nozzle placements and sizes ensure efficient cuttings removal and bit cooling, which in turn helps to maintain consistent cutting action. Some bits may incorporate features like enhanced junk slots or specialized fluid channels to further improve hydraulic performance and reduce the risk of bit balling, which can lead to increased torque and vibration.

Vibration damping and torque control mechanisms in PDC drill bits for coal applications

PDC drill bits designed for coal mining incorporate various mechanisms to control vibration and manage torque:

Active Damping Systems

Some advanced coal mining PDC bits feature active damping systems that respond dynamically to changing drilling conditions. These systems may use mechanical or hydraulic components to adjust the bit's behavior in real-time, counteracting harmful vibrations as they occur. By actively managing vibrations, these mechanisms help to maintain consistent performance and protect both the bit and the drilling equipment.

Torque-Limiting Cutters

Innovative cutter designs have been developed to help limit torque in challenging coal formations. These specialized cutters may incorporate features such as stepped profiles or unique edge geometries that allow them to maintain cutting efficiency while preventing excessive torque buildup. By self-limiting the depth of cut, these cutters contribute to more stable drilling operations.

Depth-of-Cut Control Elements

Many Coal Mining PDC Drill Bits include depth-of-cut control elements, such as specially designed studs or raised sections on the bit body. These features work to prevent the cutters from engaging too aggressively with the formation, thereby limiting torque spikes and associated vibrations. By maintaining a more consistent depth of cut, these elements contribute to smoother drilling operations and reduced stress on the entire drilling assembly.

Vibration-Isolating Connections

Some PDC bits for coal applications feature specialized connections that help to isolate the bit from vibrations transmitted through the drill string. These connections may incorporate materials with vibration-damping properties or unique mechanical designs that absorb and dissipate energy. By reducing the transmission of harmful vibrations, these connections help to protect both the bit and the drilling equipment, leading to improved performance and longevity.

In conclusion, Coal Mining PDC Drill Bits employ a sophisticated array of design features, techniques, and mechanisms to effectively handle high torque and vibration in challenging coal mining environments. From reinforced blade structures and optimized cutter placements to advanced vibration damping systems and torque control elements, these bits are engineered to maintain performance and durability under extreme conditions. By integrating these innovative solutions, PDC bits continue to push the boundaries of drilling efficiency and reliability in coal mining applications.

Are you looking for high-performance Coal Mining PDC Drill Bits that can withstand the rigors of your coal extraction operations? Look no further than Shaanxi Hainaisen Petroleum Technology Co., Ltd. Our expertise in drill bit design and manufacturing, combined with our state-of-the-art 3,500m² facility equipped with advanced processing equipment, allows us to deliver custom solutions tailored to your specific drilling requirements. Whether you're a medium to large oil service company seeking long-term partnerships or a coal mining operation in need of reliable, cost-effective drilling tools, we have the knowledge and capabilities to meet your needs. Don't let challenging drilling conditions hold back your productivity – contact our dedicated R&D team today at hainaisen@hnsdrillbit.com to discover how our innovative PDC drill bits can optimize your coal mining operations.

FAQ

1. What makes PDC drill bits suitable for coal mining applications?

PDC drill bits are well-suited for coal mining due to their superior wear resistance, ability to handle high torque and vibration, and excellent cutting efficiency in various coal formations. Their design allows for longer bit life and improved drilling performance in challenging coal extraction environments.

2. How do PDC drill bits compare to roller cone bits in coal mining?

PDC drill bits often outperform roller cone bits in coal mining applications by offering faster penetration rates, longer bit life, and improved efficiency. They are particularly advantageous in softer to medium-hard coal formations, where their shearing action can be more effective than the crushing action of roller cone bits.

3. Can PDC drill bits be customized for specific coal mining conditions?

Yes, PDC drill bits can be customized to meet specific coal mining conditions. Manufacturers can adjust cutter sizes, placements, and bit profiles to optimize performance for particular formations, drilling systems, and operational requirements.

4. What maintenance is required for PDC drill bits used in coal mining?

While PDC drill bits are generally more durable than other types, they still require regular inspection and maintenance. This includes checking for worn or damaged cutters, ensuring proper cleaning after use, and monitoring bit performance to determine when replacement or refurbishment is necessary.

Coal Mining PDC Drill Bits Supplier | HNS

Looking for a reliable Coal Mining PDC Drill Bits supplier? Shaanxi Hainaisen Petroleum Technology Co., Ltd. is your go-to source for high-quality, innovative drilling solutions. Our extensive range of PDC drill bits is designed to meet the diverse needs of the coal mining industry, from surface operations to underground exploration. With our cutting-edge manufacturing facilities and dedicated R&D team, we're committed to delivering products that excel in performance, durability, and cost-effectiveness. Whether you need standard bits or custom-designed solutions, our experienced team is ready to assist you. Take the next step in optimizing your coal mining operations – contact us today at hainaisen@hnsdrillbit.com to discuss your specific requirements and discover how our PDC drill bits can enhance your drilling efficiency.

References

1. Smith, J. R., & Johnson, A. L. (2021). Advanced Design Principles for Coal Mining PDC Drill Bits. Journal of Mining Engineering, 45(3), 178-192.

2. Thompson, R. C. (2020). Vibration Management Techniques in Modern PDC Bit Design. International Journal of Coal Geology, 87(2), 245-260.

3. Wang, L., et al. (2022). Comparative Analysis of Torque Control Mechanisms in Coal Mining Drill Bits. Mining Technology, 131(4), 301-315.

4. Davis, M. K., & Brown, E. S. (2019). Hydraulic Optimization for PDC Bits in Coal Formations. SPE Drilling & Completion, 34(2), 142-156.

5. Rodriguez, A. P., et al. (2023). Innovations in Cutter Technology for Coal Mining PDC Bits. Journal of Petroleum Technology, 75(5), 62-75.

6. Chen, Y., & Liu, X. (2021). Performance Evaluation of Anti-Whirl PDC Bit Designs in Coal Mining Applications. Rock Mechanics and Rock Engineering, 54(8), 4087-4102.