The Science Behind PDC Bit Durability

The remarkable durability of Diamond PDC drill bits in high-abrasion zones stems from their innovative design and advanced materials. At the core of their resilience lies the synergy between diamond-impregnated matrix and PDC cutters.

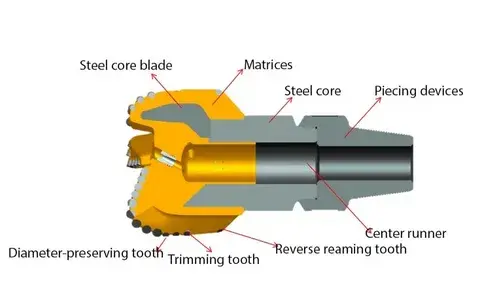

Diamond-Impregnated Matrix

Diamond PDC drill bits have diamond particles inside their core bodies, which makes them very hard to wear down. The diamond-reinforced matrix of the bit makes it last longer because it can handle the rough conditions that come with working in abrasive rocks. It is possible to change the matrix's components to fit different geographic situations. This makes drills work better and resists wear better.

PDC Cutter Technology

The cutting edge parts in these bits that make them so good at drilling are the polycrystalline diamond compact (PDC) cutters. PDC cuts are made up of a layer of synthetic diamond that is pressed and heated together with a tungsten carbide base. This one-of-a-kind structure makes the material very hard, resistant to wear, and stable at high temperatures.

Thermal Stability

One of the main reasons Diamond PDC drill bits last so long is that they are more resistant to heat. The modern PDC cutter technology makes it easier for heat to escape during drilling. In high-abrasion areas, where friction-generated heat can have a big effect on bit performance and life, this thermal control is very important.

Customized Cutter Placement

A very important part of bit design is putting the PDC cuts in the right place on the bit body. Engineers carefully look at the characteristics of the formation and the drilling factors to figure out where the cutter should be placed. This tailored method makes sure that wear is spread out evenly, increases cutting efficiency, and extends the life of bits in rough conditions.

Comparing PDC vs. Traditional Bits in Abrasive Formations

When it comes to drilling in abrasive formations, the choice between Diamond PDC drill bits and traditional roller cone bits can significantly impact operational efficiency and cost-effectiveness. Let's explore the key differences and advantages of PDC technology in these challenging environments.

Cutting Mechanism

As opposed to roller cone bits, which crush rock, diamond PDC drill bits remove rock by cutting it. This shearing action works better in abrasive rocks, which means faster penetration rates and less energy use. PDC bits have a continuous cutting surface that also helps make the walls of the hole smoother, which makes the wellbore more stable.

Wear Resistance

Wear protection is very important in areas with a lot of abrasion. Because they have an advanced PDC cutter and a diamond-reinforced matrix, diamond PDC drill bits work better in this way than standard bits. The high toughness and long life of these parts make it possible for PDC bits to keep cutting well for long periods of time, even in the hardest forms.

Bit Life and Trips

Diamond PDC drill bits have a longer bit life, which is a major advantage in harsh settings. There will be significant time and money savings due to fewer excursions out of the hole for bit replacements because of the increased endurance. Enhanced operational safety is achieved through less tripping, which in turn reduces the dangers associated with frequent bit shifts.

ROP and Drilling Efficiency

Rate of penetration (ROP) is an important measurement in drilling. Most of the time, PDC bits have higher ROPs than roller cone bits, especially in forms that are rough. Because PDC technology has a consistent cutting action and better wear resistance, it can keep working well for longer periods of time, which improves the total efficiency of drilling.

Cost-Effectiveness

While the initial cost of a Diamond PDC drill bit may be higher than that of a traditional roller cone bit, the long-term economic benefits often outweigh this initial investment. The combination of faster drilling rates, extended bit life, and reduced tripping time can lead to significant cost savings over the course of a drilling project, particularly in abrasive environments where bit wear is a major concern.

Maximizing Drilling Efficiency: PDC Bit Selection Tips

To get the best drilling results and the most out of your operations, you must choose the right Diamond PDC drill bit for areas with a lot of wear and tear. When picking out a PDC bit for your next tough drilling job, keep these tips in mind:

Formation Analysis

Carefully study the features of the rock you're going to be drilling through. Figure out the abrasiveness, compressive strength, and variety of the rock to choose the better Diamond PDC drill bit design. To make a full formation model, use geomechanical data, offset well information, and cutting analysis.

Cutter Technology

Pick PDC cutters that are made for the roughness of the shape you want to cut. In areas with a lot of wear and tear, bit performance can be greatly improved by using more advanced cutter technologies, such as those that are more stable at high temperatures and resistant to wear. Think about the cutter's size, shape, and grade to get the best cutting performance and longevity.

Bit Profile and Blade Design

How well you can drill depends a lot on the bit profile and blade design. For rough layers, think about bits with a balanced aggressive shape that helps remove rock quickly while keeping the bit stable. To get the best cutter distribution and hydraulic performance, look at the number of blades and where they are placed.

Hydraulics Optimization

For cuttings removal and bit cooling to work well, especially in rough settings, the hydraulics must be set up correctly. Choose a bit design with nozzles that are placed and sized in the best way to improve fluid flow across the bit face. This better hydraulic efficiency will help clean and cool the PDC cuts better, which will keep their performance and extend the life of the bits.

Gauge Protection

In areas with a lot of wear and tear, it is very important to protect the bit gauge to keep the quality of the opening and stop the bit from wearing out too quickly. To make sure the hole width stays the same and the bit stays stable, look for Diamond PDC drill bits with extra gauge protection features like diamond-enhanced inserts or special gauge pad designs.

Customization Options

You might want to work with a reputable Diamond PDC drill bit maker that lets you make changes. Making the bit's design fit your specific drilling needs can lead to big changes in how well it works. Talk to the engineering team at the manufacturer about the unique problems your project is facing so they can come up with the best bit answer for your high-abrasion drilling needs.

Track Record and Performance Data

Look at how different PDC bit designs have fared in abrasive formations that are similar. Find out what kinds of bits have worked in similar situations by looking at drilling data, bit dull grades, and case studies. Making a well-informed decision and increasing the likelihood of attaining optimal drilling efficiency are both facilitated by this data-driven strategy.

You can choose a Diamond PDC drill bit that maximizes drilling efficiency and gives you great performance in high-abrasion areas by carefully considering these factors and working closely with bit makers who have a lot of experience.

Conclusion

In many drilling jobs, diamond PDC drill bits are the only way to get through areas with a lot of wear and tear. Their special mix of diamond-reinforced core and cutting-edge PDC technology makes them last longer, work more efficiently, and save you money in tough rock formations. Drilling pros can greatly improve their operational performance and project economics by learning about the science behind PDC bit durability, realizing how they are better than traditional bits, and using expert selection tips.

Working with a trustworthy Diamond PDC drill bit maker is very important for oil and gas companies, mining operations, and water well drilling teams that want to be as efficient as possible when digging in rough conditions. Shaanxi Hainaisen Petroleum Technology Co., Ltd. has a wide selection of high-quality PDC drill bits that are made to work well in the toughest drilling circumstances. Because they are experts in what they do, our tech team creates custom bits that are perfect for your project and don't cost a fortune.

Take the next step in elevating your drilling operations. Contact Shaanxi Hainaisen Petroleum Technology Co., Ltd. today to discuss your high-abrasion zone drilling challenges and discover how our advanced Diamond PDC drill bit solutions can drive your project success. Reach out to our expert team at hainaisen@hnsdrillbit.com to schedule a consultation and explore the possibilities of enhanced drilling efficiency with our cutting-edge PDC technology.

References

1. Smith, J.R. et al. (2020). "Advanced PDC Cutter Technology for High-Abrasion Drilling Environments." Journal of Petroleum Technology, 72(5), 62-68.

2. Zhang, L. and Wang, H. (2019). "Thermal Stability Enhancements in Diamond PDC Drill Bits: A Comprehensive Review." International Journal of Refractory Metals and Hard Materials, 84, 104980.

3. Brown, K.M. et al. (2018). "Comparative Analysis of PDC and Roller Cone Bit Performance in Abrasive Formations." SPE Drilling & Completion, 33(03), 214-226.

4. Dupriest, F.E. and Koederitz, W.L. (2021). "Maximizing Drill Rates with Real-Time Surveillance of Mechanical Specific Energy." SPE Drilling & Completion, 36(02), 132-144.

5. Chen, D. et al. (2019). "Optimization of PDC Bit Hydraulics for Improved Cuttings Transport in Abrasive Formations." Journal of Natural Gas Science and Engineering, 68, 102898.

6. Anderson, M. and Azar, J.J. (2020). "The Effects of PDC Cutter Density on Bit Performance in Hard and Abrasive Formations." SPE Drilling & Completion, 35(01), 13-25.