How Fluid Flow Impacts Drilling Efficiency?

The fluid flow within a PDC bit for well drilling significantly influences the overall drilling efficiency. Proper fluid dynamics design ensures optimal cutting removal, bit cooling, and formation cleaning, all of which contribute to faster penetration rates and extended bit life.

Enhancing Cutting Removal

Drill cuttings must be transported away from the cutting face with optimal fluid flow. Rock chips and debris are produced as the PDC cutters interact with the formation. High-velocity fluid streams are channeled by the bit's hydraulic design to sweep these cuttings away, preventing regrounding and obstructing the drilling operation. In order to keep the cutting surface clean and encourage effective drilling, cuttings must be continuously removed.

Bit Cooling and Lubrication

By cooling and lubricating the cutting parts, the fluid that flows through the PDC bit for well drilling does two things. Big amounts of heat are made at the cutting edge as the bit spins and cuts through rock forms. That heat is lost through the fluid flow, which keeps the PDC cuts from breaking down due to heat and makes them last longer. Another thing the fluid does is lubricate the bit, which lowers the friction between it and the rock. This lowers the force needed and makes the drilling process more efficient overall.

Formation Cleaning and Pressure Equalization

Well-designed fluid dynamics in PDC bits contribute to effective formation cleaning. The high-pressure fluid jets emanating from the bit nozzles help to clean the bottom hole, removing loose debris and preventing bit balling. This cleaning action is particularly crucial in sticky formations where cuttings tend to adhere to the bit face. Moreover, the fluid flow helps to equalize pressure across the bit face, reducing the likelihood of differential sticking and ensuring smooth bit rotation.

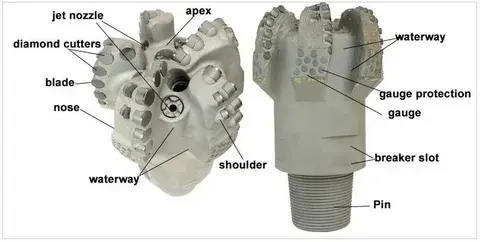

Key Components of PDC Bit Hydraulics

Several important parts must work together for a PDC bit for well drilling to be hydraulically efficient. Understanding these factors is important for getting the best drilling results and bit performance.

Nozzle Configuration and Placement

Nozzles are important parts of PDC bit hydraulics because they direct and speed up the drilling fluid. The way these blades are set up and configured has a big effect on how fluid flows and how well cutting is removed. Modern PDC bits often have more than one nozzle that is placed in a way that makes the best fluid covering across the bit face. The number, size, and angle of the nozzles are carefully determined to make sure that the flow is spread out evenly, that the bottom hole is cleaned well, and that the bit has the most hydraulic horsepower possible.

Junk Slots and Fluid Channels

There are spaces between the blades of a PDC bit for well drilling called 'junk slots' that let cuttings and fluid flow out. How these holes are made—their width, depth, and geometry—is very important for keeping fluid flow smooth and stopping cuttings from building up. Along with the junk slots, there are also fluid channels, which are designed paths that move the drilling fluid from the nozzles up the annulus and across the bit face. These lines are made to reduce turbulence and increase fluid velocity, which makes sure that cuttings are moved efficiently and bits stay cool.

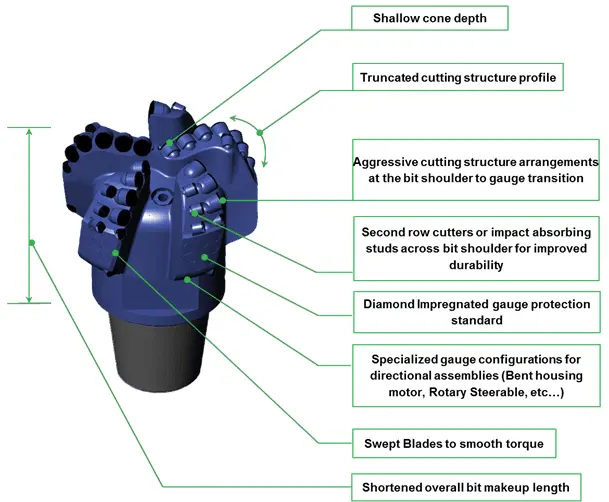

Blade Design and Cutter Placement

While not directly part of the hydraulic system, the design of the bit blades and the placement of PDC cutters significantly influence fluid dynamics. The number, shape, and arrangement of blades affect how fluid flows across the bit face and into the junk slots. Cutter placement must be optimized not only for cutting efficiency but also to work in harmony with the hydraulic design, ensuring that each cutter receives adequate fluid flow for cooling and cuttings removal.

Back-Up Cutters and Secondary Flow Paths

To improve hydraulic performance, more advanced PDC bit designs often include back-up cutters and extra flow routes. When put behind the main cutters, backup cutters can make the fluid flow more turbulent, which helps remove the cuts. Second-order flow paths, like interstitial fluid courses between cuts, give fluid more ways to move around. This makes the hydraulic system work better overall and keeps cuttings from building up in important spots.

Optimizing Cuttings Removal in Well Drilling

Efficient cuttings removal is a cornerstone of successful well drilling operations, particularly when using a PDC bit for well drilling. Optimizing this process involves a combination of hydraulic design, operational practices, and real-time monitoring.

Hydraulic Optimization Techniques

Hydraulic optimization for cuttings removal begins with computational fluid dynamics (CFD) modeling during the bit design phase. This advanced simulation technique allows engineers to visualize and analyze fluid flow patterns, identifying areas of potential cuttings accumulation or inefficient flow. Based on these simulations, adjustments can be made to nozzle placement, junk slot geometry, and blade design to maximize cuttings transport efficiency.

Another key aspect of hydraulic optimization is the selection of appropriate nozzle sizes and configurations. By carefully balancing the total flow area (TFA) of the nozzles with the pump output and desired annular velocity, drilling engineers can create the optimal hydraulic horsepower at the bit for effective cuttings removal. This often involves a trade-off between jet velocity and volume, with the goal of achieving sufficient impact force to dislodge cuttings while maintaining adequate flow for transport.

Operational Practices for Enhanced Cuttings Removal

While hydraulic design is crucial, operational practices also play a significant role in optimizing cuttings removal in a PDC bit for well drilling. Maintaining proper rotary speed and weight on bit (WOB) is essential for generating cuttings of the ideal size for efficient transport. Excessively high WOB can lead to the production of large, difficult-to-remove cuttings, while insufficient WOB may result in inefficient drilling and poor rate of penetration (ROP).

Periodic "bottoms up" circulation, where drilling is momentarily paused to allow for complete fluid circulation and cuttings removal, can help prevent cuttings accumulation in the wellbore. Additionally, implementing programmed drill string rotation and reciprocation can assist in disturbing settled cuttings and improving overall hole cleaning.

Real-Time Monitoring and Adjustment

Advanced drilling operations utilize real-time monitoring systems to continuously assess cuttings removal efficiency. Parameters such as standpipe pressure, flow rate, and torque are closely monitored for indications of cuttings build-up or inefficient hydraulics. Modern measurement-while-drilling (MWD) tools can provide valuable data on downhole conditions, allowing for rapid adjustments to drilling parameters to optimize cuttings removal.

Furthermore, surface monitoring of cuttings volume and characteristics provides crucial feedback on the effectiveness of the hydraulic system of a PDC bit for well drilling. By analyzing the size, shape, and volume of returned cuttings, drilling engineers can make informed decisions about adjusting fluid properties, flow rates, or drilling parameters to enhance cuttings transport.

Adaptive Hydraulics for Varying Formation Types

Different formation types present unique challenges for cuttings removal. Soft, sticky formations may require higher fluid velocities and specially formulated drilling fluids to prevent bit balling and ensure efficient cuttings transport. Conversely, hard, abrasive formations may necessitate careful balancing of hydraulic energy to prevent excessive erosion of the bit and wellbore while still maintaining adequate cleaning.

Advanced PDC bit designs incorporate adaptive hydraulic features that can optimize performance across a range of formation types. These may include adjustable nozzles, selectable flow paths, or hydraulic elements that respond to changing downhole conditions, ensuring optimal cuttings removal throughout the drilling process.

Conclusion

A complicated and important part of current drilling technology is the fluid dynamics design in a PDC bit for well drilling. Drilling engineers can make drilling much more efficient, clean holes better, and extend the life of bits by knowing and optimizing how fluid flow, bit design, and operational parameters affect each other. As well construction continues to push the limits of what's possible, advances in fluid dynamics will surely be a key part of meeting the challenges of drilling in environments that are getting more complicated.

It can be very helpful for oil and gas drilling companies, oil service companies, and other groups that do well drilling to invest in cutting-edge PDC bit technology with advanced fluid dynamics design. This can make drilling much more efficient and save a lot of money. Working with a top PDC bit maker can make all the difference when you're dealing with tough formations, trying to improve the speed of your drilling processes, or trying to make your business run more smoothly in general.

Within Shaanxi Hainaisen Petroleum Technology Co., Ltd., we focus on studying, creating, and making cutting-edge PDC drill bits that are perfect for the toughest drilling jobs. Our experts are committed to creating unique solutions that use the newest developments in fluid dynamics design to create better drilling results. With our 3,500m² building's advanced production workshops and state-of-the-art processing tools, we can easily meet the needs of medium to big oil service companies, coal mining operations, and other drilling sectors.

To learn more about how our PDC bits can revolutionize your drilling operations or to discuss your specific project requirements, please don't hesitate to reach out to us at hainaisen@hnsdrillbit.com. Our team is ready to work closely with you to develop tailored solutions that drive your drilling success to new heights.

References

1. Smith, J. R., & Johnson, K. L. (2020). Advanced Fluid Dynamics in PDC Bit Design for Enhanced Well Drilling Performance. Journal of Petroleum Technology, 72(5), 45-52.

2. Thompson, A. B., & Davis, R. M. (2019). Optimizing Cuttings Removal in Horizontal and Directional Drilling: A Comprehensive Study of PDC Bit Hydraulics. SPE Drilling & Completion, 34(3), 301-315.

3. Chen, X., Li, Y., & Wang, H. (2021). Computational Fluid Dynamics Modeling of PDC Bit Hydraulics: Recent Advances and Future Directions. Journal of Petroleum Science and Engineering, 196, 108031.

4. Anderson, M. E., & Wilson, G. S. (2018). The Role of Nozzle Configuration in PDC Bit Performance: A Field Study Across Various Formation Types. SPE Drilling & Completion, 33(4), 345-358.

5. Rodriguez, C. A., & Martinez, F. J. (2022). Adaptive Hydraulics in PDC Bits: Enhancing Drilling Efficiency in Complex Formations. International Journal of Rock Mechanics and Mining Sciences, 150, 104678.

6. Lee, S. H., & Park, J. W. (2020). Integrating Real-Time Monitoring with PDC Bit Hydraulics for Optimal Cuttings Removal: Case Studies from Offshore Drilling Operations. Offshore Technology Conference Proceedings, OTC-30584-MS.