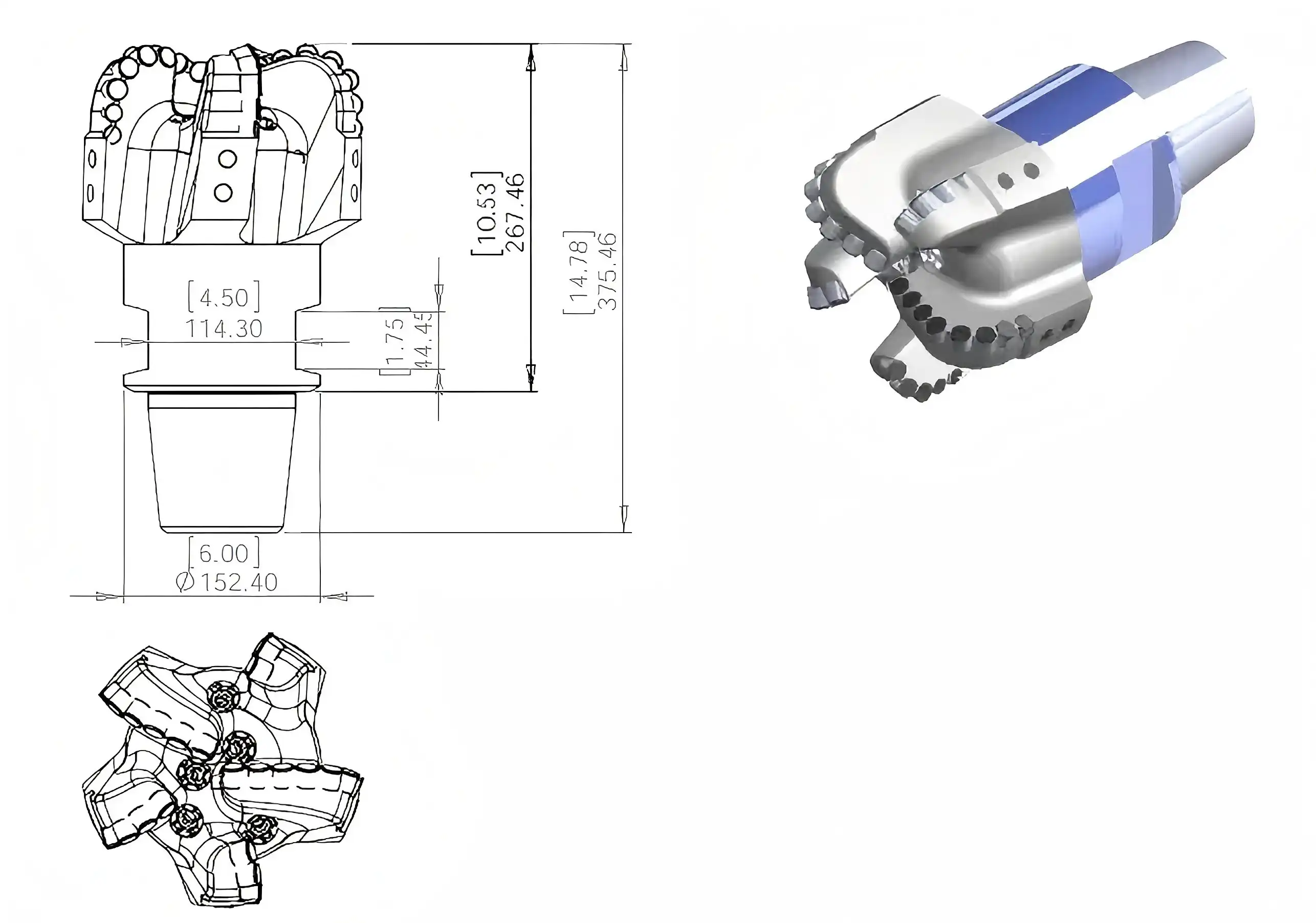

Blade Geometry: Key to Enhanced Drilling Efficiency

When it comes to how well a 5 Blades PDC Oil Bit drills, the shape of the blades is very important. A lot of things need to be carefully thought through in order to optimize blade geometry. These include the number of blades, their length, and their outline. The bit's general performance and its ability to remove rock while staying stable are affected by each of these parts.

Blade Count and Spacing

The five-blade configuration offers an optimal balance between cutting efficiency and stability. This design allows for sufficient space between blades to accommodate an adequate number of cutters while ensuring proper fluid flow and cuttings evacuation. The spacing between blades is carefully calculated to maximize rock removal without compromising the bit's structural integrity or hydraulic performance.

Blade Length and Profile

The length and profile of each blade in a 5 Blades PDC Oil Bit are designed to optimize the bit's contact with the formation, longer blades provide more surface area for cutter placement, allowing for a more aggressive cutting action, however, blade length must be balanced with the need for adequate junk slot area to facilitate efficient cuttings removal, and the blade profile, which can be straight, spiral, or a combination of both, is tailored to specific formation characteristics and drilling requirements, with a well-designed blade profile ensuring even wear distribution across the bit face, prolonging bit life and maintaining consistent performance throughout the drilling operation.

Blade Orientation and Angle

The orientation and angle of the blades relative to the bit axis significantly impact drilling efficiency. Optimizing these parameters helps to control the bit's aggressiveness and stability. Blade orientation can be adjusted to enhance the bit's ability to maintain a straight hole or to improve its directional drilling capabilities. The blade angle, or rake angle, influences the cutting action and the amount of force required to remove rock. A carefully optimized blade angle ensures efficient rock removal while minimizing the risk of bit damage or premature wear.

Cutter Placement Strategies for Improved Rock Removal

Effective cutter placement is essential for maximizing the performance of a 5 Blades PDC Oil Bit. Strategic positioning of cutters on the bit face and blades ensures efficient rock removal, even wear distribution, and optimal force transmission. Cutter placement strategies must consider various factors, including cutter size, density, and arrangement patterns.

Cutter Size and Density

The size and density of cutters on a 5 Blades PDC Oil Bit are carefully selected based on the target formation characteristics and drilling parameters. Larger cutters provide greater durability and are suitable for harder formations, while smaller cutters offer increased aggressiveness and are ideal for softer formations. Cutter density, or the number of cutters per blade, is optimized to balance cutting efficiency with hydraulic performance. Higher cutter density can improve penetration rates but may compromise cuttings evacuation if not properly balanced with adequate junk slot area.

Cutter Arrangement Patterns

The arrangement of cutters on the bit face and blades significantly influences drilling efficiency and bit stability. Common cutter arrangement patterns include:

- Spiral patterns: Enhance bit stability and improve cuttings removal

- Radial patterns: Provide aggressive cutting action and are suitable for softer formations

- Combination patterns: Offer a balance between stability and aggressiveness

Back-up Cutter Placement

Back-up cutters play a crucial role in maintaining bit performance as the primary cutters wear. Strategically placed back-up cutters help to:

- Extend bit life by taking over cutting duties as primary cutters wear

- Improve bit stability by providing additional contact points with the formation

- Enhance cutting efficiency in harder or more abrasive formations

The placement of back-up cutters is carefully optimized to complement the primary cutter arrangement and maximize overall bit performance.

Balancing Aggressiveness and Durability in Bit Design

When making a 5 Blades PDC Oil Bit, it's important to find the right mix between how aggressive it is and how long it will last. This balance has a direct effect on the bit's ability to keep up high entry rates and last a long time in tough drilling conditions. Getting the best balance here requires careful thought about the exposure of the cutter, the shape of the blades, and the choice of material.

Cutter Exposure and Depth of Cut Control

The bit's aggression is affected by cutter exposure, which is the amount of cutter that sticks out from the bit body. In general, a higher cutter exposure makes the cutting action more aggressive, but in harder forms, it may make the cutter less durable. Depth of cut control features, like limiters or deflectors, can be built into the bit's design to keep the cutter from going too deep and to protect against damage from impacts. By carefully adjusting the cutter's exposure and adding depth of cut control features, engineers can make bits that can drill deeply into a variety of formations and still last a long time.

Blade and Bit Body Design

How the blades and bit body of a 5 Blades PDC Oil Bit are made has a big effect on how sharp they are and how long they last, while thicker blades make the bit last longer, they may make it harder to drill through harder layers, thinning blades, on the other hand, allow more entry but may be easier to damage, and the design of the bit body, which includes things like reinforced shoulder areas and better hydraulic lines, makes it last longer while still cutting well, allowing engineers to make bits that work well and last a long time in certain drilling conditions by carefully balancing these design features.

Material Selection and Surface Treatments

Picking the right materials for the bit's body, blades, and cutters is very important for getting the right mix of toughness and longevity. Modern materials, like high-quality steel for the bit body and tungsten carbide for the matrix, make it last longer without lowering its cutting ability. To make things last even longer, surface treatments like hardfacing and diamond-enhanced inserts can be used on places that get a lot of use. The types of cutter materials and grades used are chosen based on the properties of the shape, which guarantees their best performance and durability.

Customization for Specific Drilling Conditions

Recognizing that drilling conditions vary widely across different projects and formations, the ability to customize the balance between aggressiveness and durability is essential. This customization may involve:

- Adjusting cutter density and exposure for specific formation types

- Modifying blade profiles to optimize cutting action in particular drilling environments

- Incorporating specialized features, such as anti-whirl technology or enhanced stabilization elements, for challenging drilling conditions

Conclusion

It's hard to find the best cutting designs for a 5 Blades PDC Oil Bit because there are so many things to think about. Manufacturers can make very effective and long-lasting bits for different drilling situations by paying attention to blade geometry, cutter placement strategies, and the balance between aggressiveness and durability. As drilling technologies keep getting better, cutting structure optimization research and development will be very important for pushing the limits of how well and how efficiently drilling can be done.

Investing in optimized 5 Blades PDC Oil Bits can help oil and gas drilling companies, oil service companies, and other businesses that need advanced drilling solutions improve drilling efficiency, cut down on downtime, and save money overall. A company called Shaanxi Hainaisen Petroleum Technology Co., Ltd. does research, development, and production of high-tech PDC drill bits. They make customized 5 Blades PDC Oil Bits that are made to fit the needs of your drilling activities. Our state-of-the-art 3,500m² building has cutting-edge processing tools and a dedicated research and development (R&D) team. We are dedicated to providing you with new drilling solutions that will help you succeed.

To learn more about how our optimized 5 Blades PDC Oil Bits can enhance your drilling performance and efficiency, please contact our team of experts at hainaisen@hnsdrillbit.com. Let us help you unlock the full potential of your drilling operations with our cutting-edge bit technology.

References

1. Smith, J. R., & Johnson, T. K. (2022). Advancements in PDC Bit Design: Optimizing Cutting Structures for Enhanced Performance. Journal of Petroleum Technology, 74(5), 62-71.

2. Anderson, M. E., & Williams, R. C. (2021). The Impact of Blade Geometry on PDC Bit Efficiency in Various Formation Types. SPE Drilling & Completion, 36(3), 245-257.

3. Lee, S. H., & Chen, Y. Q. (2023). Cutter Placement Strategies for Improved Rock Removal in PDC Bits. International Journal of Rock Mechanics and Mining Sciences, 152, 105087.

4. Thompson, K. L., & Roberts, D. P. (2022). Balancing Aggressiveness and Durability in Modern PDC Bit Designs. SPE/IADC Drilling Conference and Exhibition, SPE-208770-MS.

5. Garcia, A. R., & Martinez, E. S. (2021). Customization Techniques for PDC Bits in Challenging Drilling Environments. Offshore Technology Conference, OTC-31123-MS.

6. Brown, N. J., & Davis, L. M. (2023). The Role of Advanced Materials in Enhancing PDC Bit Performance and Longevity. Materials Science and Engineering: A, 845, 143320.