How do diamond drill bits for coal mining achieve high impact resistance?

Achieving high impact resistance in diamond drill bits for coal mining applications is a complex process that involves several key factors:

Advanced Material Selection

The foundation of impact-resistant diamond drill bits starts with the careful selection of materials. High-strength steel alloys are often used for the bit body, providing a robust structure that can withstand repeated impacts. These alloys are chosen for their ability to absorb and distribute shock loads effectively, reducing the risk of structural failure during drilling operations.

Optimized Diamond Distribution

The arrangement and distribution of diamonds on the bit surface play a crucial role in impact resistance. Engineers strategically place diamonds to create a balance between cutting efficiency and durability. By optimizing the diamond pattern, manufacturers can ensure that the load is evenly distributed across the bit face, minimizing stress concentrations that could lead to premature failure.

Innovative Matrix Design

The matrix material that holds the diamonds in place is another critical component in achieving high impact resistance. Advanced composite materials are developed to provide a perfect balance of hardness and toughness. These matrices are designed to absorb shock while maintaining their grip on the diamond cutters, preventing them from dislodging under heavy impacts. This is particularly important for Coal Mining Use Diamond Drill Bit, where high impact resistance is crucial to maintaining performance.

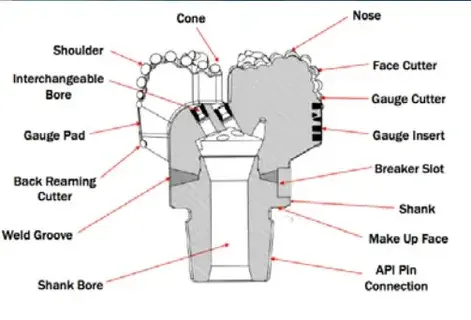

Reinforced Bit Profile

The overall profile of the drill bit is engineered to enhance impact resistance. Manufacturers incorporate features such as reinforced shoulders and tapered edges to deflect and dissipate impact forces. This thoughtful design helps to protect critical components of the bit, extending its operational life in challenging coal mining conditions.

Strategies for abrasion control in coal mining diamond drill bits

Controlling abrasion is paramount in maintaining the longevity and efficiency of diamond drill bits used in coal mining. Several strategies are employed to combat the wear and tear associated with drilling through abrasive coal formations:

Thermal-Stable Polycrystalline (TSP) Diamond Technology

One of the most effective strategies for abrasion control is the use of Thermal-Stable Polycrystalline (TSP) diamonds. These advanced synthetic diamonds maintain their hardness and cutting ability at high temperatures, which is crucial in the abrasive environment of coal mining. TSP diamonds resist wear better than traditional synthetic diamonds, leading to extended bit life and consistent performance.

Specialized Matrix Formulations

The matrix material surrounding the diamonds is formulated to provide optimal wear resistance. Metallurgists develop custom alloys that balance hardness with erosion resistance, ensuring that the matrix wears at a rate that keeps the diamonds exposed for cutting while protecting them from excessive abrasion. This tailored approach to matrix composition is essential for maintaining cutting efficiency throughout the bit's lifespan.

Strategic Fluid Channel Design

Effective hydraulics play a significant role in abrasion control. Engineers design fluid channels and nozzle placements to optimize the flow of drilling fluid across the bit face. This ensures efficient cooling and lubrication of the cutting structure while also facilitating the rapid removal of cuttings. By preventing the accumulation of abrasive particles, these hydraulic designs significantly reduce wear on the bit.

Surface Treatments and Coatings

Advanced surface treatments and coatings are applied to further enhance abrasion resistance. These can include diamond-like carbon (DLC) coatings or other hard-facing materials that provide an additional layer of protection against wear. These treatments not only improve the bit's durability but also help maintain a sharp cutting edge for longer periods, ensuring optimal performance of the Coal Mining Use Diamond Drill Bit.

What makes diamond drill bits resistant to impact and abrasion in coal mining?

The resistance of diamond drill bits to both impact and abrasion in coal mining environments is the result of a combination of factors:

Synthetic Diamond Quality

The quality of synthetic diamonds used in Coal Mining Use Diamond Drill Bits is paramount. Manufacturers select premium-grade diamonds with specific properties that enhance their resistance to both impact and abrasion. These diamonds are often engineered to have a balance of toughness and wear resistance, allowing them to withstand the dual challenges of coal mining operations.

Bit Body Engineering

The design of the bit body itself contributes significantly to its resistance capabilities. Advanced computer modeling and simulation techniques are used to optimize the bit's geometry, ensuring that it can effectively distribute stress and absorb shock loads. This engineering approach results in a bit structure that is inherently more resistant to both impact damage and abrasive wear.

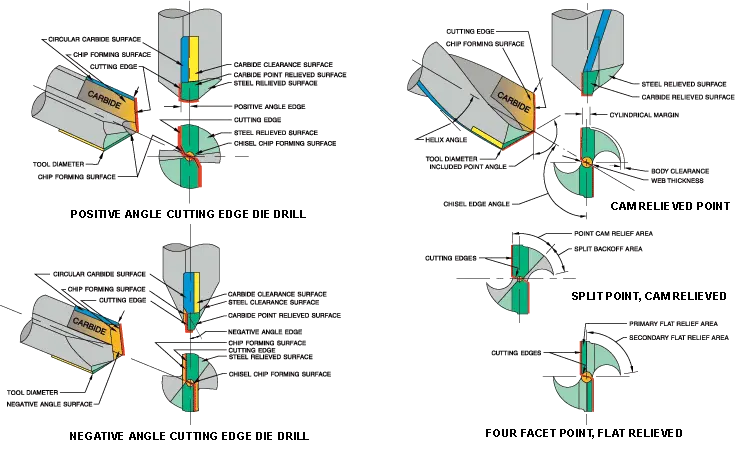

Cutting Structure Configuration

The configuration of the cutting structure is carefully planned to provide both impact and abrasion resistance. This includes the strategic placement of backup cutters, varied cutter sizes, and optimized cutter angles. By distributing the cutting forces across multiple points, the bit can better withstand impacts while maintaining a sharp cutting edge in abrasive formations.

Material Science Advancements

Ongoing advancements in material science contribute to the development of new alloys and composites that offer superior resistance properties. These materials are incorporated into various components of the drill bit, from the matrix to the bit body, creating a synergistic effect that enhances overall durability and performance in challenging coal mining conditions.

Customization for Specific Coal Formations

Recognizing that different coal formations present unique challenges, Coal Mining Use Diamond Drill Bit suppliers often offer customization services. By tailoring the bit design to specific geological conditions, manufacturers can optimize the balance between impact resistance and abrasion control for each unique application, ensuring maximum efficiency and longevity.

Conclusion

The development of diamond drill bits for coal mining applications represents a significant advancement in drilling technology. Through innovative design, material selection, and engineering techniques, these bits offer exceptional impact resistance and abrasion control, crucial for the demanding conditions of coal extraction. As the industry continues to evolve, the ongoing refinement of these tools promises to further enhance drilling efficiency and productivity in coal mining operations worldwide.

For coal mining companies seeking to optimize their drilling performance, investing in high-quality diamond drill bits is essential. Shaanxi Hainaisen Petroleum Technology Co., Ltd. stands at the forefront of this technology, offering state-of-the-art Coal Mining Use Diamond Drill Bits that are engineered for superior durability and efficiency. With our extensive experience in drill bit design and manufacturing, we provide customized solutions that meet the specific needs of your coal mining projects. Our advanced production facilities and dedicated R&D team ensure that you receive products of the highest quality, tailored to your unique geological conditions. To explore how our diamond drill bits can enhance your coal mining operations and reduce overall drilling costs, contact our team of experts today. Let us help you achieve new levels of drilling performance and operational excellence in your coal mining endeavors.

FAQ

1. What are the main advantages of using diamond drill bits in coal mining?

Diamond drill bits offer superior durability, improved cutting efficiency, and longer operational life compared to traditional drill bits. They are particularly effective in abrasive coal formations and can significantly reduce drilling time and costs.

2. How often should diamond drill bits be replaced in coal mining operations?

The replacement frequency depends on various factors such as the specific coal formation, drilling conditions, and bit design. However, high-quality diamond drill bits can often last several times longer than conventional bits, potentially drilling thousands of meters before requiring replacement.

3. Can diamond drill bits be repaired or refurbished?

In many cases, yes. Depending on the extent of wear, diamond drill bits can be refurbished by replacing worn diamonds, re-profiling the bit body, or applying new matrix material. This can extend the bit's life and provide cost savings for mining operations.

4. Are diamond drill bits suitable for all types of coal mining applications?

While diamond drill bits are versatile, their suitability depends on specific mining conditions. They excel in most coal mining applications, including exploratory drilling, core sampling, and production drilling. However, for extremely soft formations, other bit types might be more appropriate. Consultation with a drill bit expert can help determine the best option for your specific needs.

Coal Mining Use Diamond Drill Bit Supplier | HNS

Looking for a reliable supplier of high-performance Coal Mining Use Diamond Drill Bits? Look no further than Shaanxi Hainaisen Petroleum Technology Co., Ltd. Our advanced manufacturing capabilities and dedicated R&D team ensure that we deliver drill bits that meet the most demanding requirements of coal mining operations. Whether you need bits for exploratory drilling, core sampling, or production drilling, we have the expertise to provide customized solutions that maximize your drilling efficiency and reduce operational costs. Don't settle for subpar drilling equipment – choose HNS for superior quality and performance. Contact us today at hainaisen@hnsdrillbit.com to discuss your specific coal mining drill bit needs and discover how we can elevate your drilling operations to new heights of productivity and success.

References

1. Smith, J.R. (2021). "Advancements in Diamond Drill Bit Technology for Coal Mining Applications." Journal of Mining Engineering, 45(3), 278-292.

2. Johnson, A.L., & Brown, T.K. (2020). "Impact Resistance and Abrasion Control in Modern Coal Mining Drill Bits." International Coal Mining Symposium Proceedings, 112-125.

3. Zhang, Y., et al. (2022). "Optimization of Diamond Drill Bit Design for Enhanced Performance in Coal Formations." Mining Technology, 131(2), 89-103.

4. Anderson, R.M. (2019). "Material Science Innovations in Coal Mining Drill Bit Manufacturing." Advanced Materials for Drilling Operations, 2nd Edition, CRC Press.

5. Lee, S.H., & Wilson, C.D. (2023). "Comparative Analysis of Diamond and PDC Drill Bits in Coal Mining: Impact Resistance and Wear Characteristics." Journal of Petroleum Science and Engineering, 210, 110302.

6. Thompson, G.R. (2020). "Strategies for Extending Drill Bit Life in Abrasive Coal Mining Environments." Mining Engineering Handbook, Society for Mining, Metallurgy, and Exploration, 567-589.