What cutter layout defines a standard 5-blade PDC oil bit?

The cutter layout of a standard 5-blade PDC Oil Bit is a crucial aspect of its design, directly influencing its drilling performance and efficiency. This layout is meticulously engineered to optimize cutting action, stability, and wear resistance across various formation types.

Radial Distribution of Cutters

In an ordinary 5-blade setup, PDC cutters are deliberately situated along each edge in a spiral design. This course of action guarantees a comprehensive scope of the borehole, permitting effective shake evacuation and smooth penetrating movement. The outspread conveyance moreover makes a difference in keeping up bit stability by equitably conveying the cutting powers over the bit face.

Cutter Density and Sizing

The cutter thickness and measuring on a 5-blade PDC bit are carefully calculated to adjust forcefulness and strength. By and large, bigger cutters are put on the external parcels of the edges to withstand the higher speeds and powers experienced at the bit's outskirts. Littler, more various cutters are frequently utilized in the center of the bit to upgrade ROP in milder formations.

Back Rake and Side Rake Angles

The back rake and side rake points of the cutters play an imperative part in the bit's execution. These points are optimized to give the best adjustment between cutting effectiveness and cutter life span. Ordinarily, cutters on a 5-blade PDC bit have a back rake point extending from 15 to 25 degrees, with varieties depending on the particular arrangement requirements.

Spiral Arrangement

The cutters on a 5-blade PDC bit are frequently organized in a winding design. This plan highlights guarantees that each cutter locks in the arrangement at a somewhat diverse time, lessening vibration and making strides generally penetration smoothness. The winding course of action also helps in productive cutting departures, avoiding bit balling and upgrading pressure-driven performance.

Blade count impact: 5-blade PDC oil bit vs others

The number of blades on a PDC oil bit significantly influences its drilling characteristics and performance. The 5 Blades PDC Oil Bit offers a unique set of advantages that set it apart from its counterparts with different blade counts.

Comparison with 3-Blade and 4-Blade PDC Bits

When compared to 3-blade and 4-blade PDC bits, the 5-blade arrangement offers upgraded soundness and decreased vibration. The extra edges give more points of contact with the borehole divider, resulting in smoother boring operations and improved borehole quality. This expanded solidness is especially useful in directional penetrating applications, where maintaining an exact direction is crucial.

Advantages over 6-Blade and 8-Blade PDC Bits

While 6-blade and 8-blade PDC bits offer the most extreme soundness, they can some of the time give up Rate of Entrance (ROP) due to expanded contact region with the formation. The 5-blade plan strikes an ideal adjust between solidity and power, permitting for quicker penetrating speeds while keeping up satisfactory control.

Formation-Specific Performance

The 5-blade configuration is particularly well-suited for medium hardness formations with low compressive strength, such as shale, limestone, and sandstone. In these formations, the 5 Blades PDC Oil Bit can achieve higher ROP compared to bits with more blades, while still providing the stability needed for efficient drilling.

Hydraulic Efficiency

The 5-blade plan offers a fabulous compromise in terms of pressure-driven effectiveness. It gives an adequate garbage opening zone for successful cutting and learning, whereas the edge check is tall sufficient to guarantee appropriate conveyance of water-powered energy over the bit confront. This adjustment contributes to making strides in borehole cleaning and bit cooling.

Nozzle placement and hydraulics in 5-blade PDC oil bits

The hydraulic system of a 5-blade PDC Oil Bit plays a crucial role in its overall performance. Proper nozzle placement and optimized hydraulics ensure efficient cuttings removal, adequate bit cooling, and enhanced drilling efficiency.

Strategic Nozzle Positioning

In a 5-blade PDC bit, spouts are regularly situated between the edges to maximize liquid stream productivity. This key arrangement permits ideal dissemination of water-powered vitality over the bit, guaranteeing careful cleaning of the cutters and effective transport of bore cuttings absent from the bit.

Nozzle Count and Size Optimization

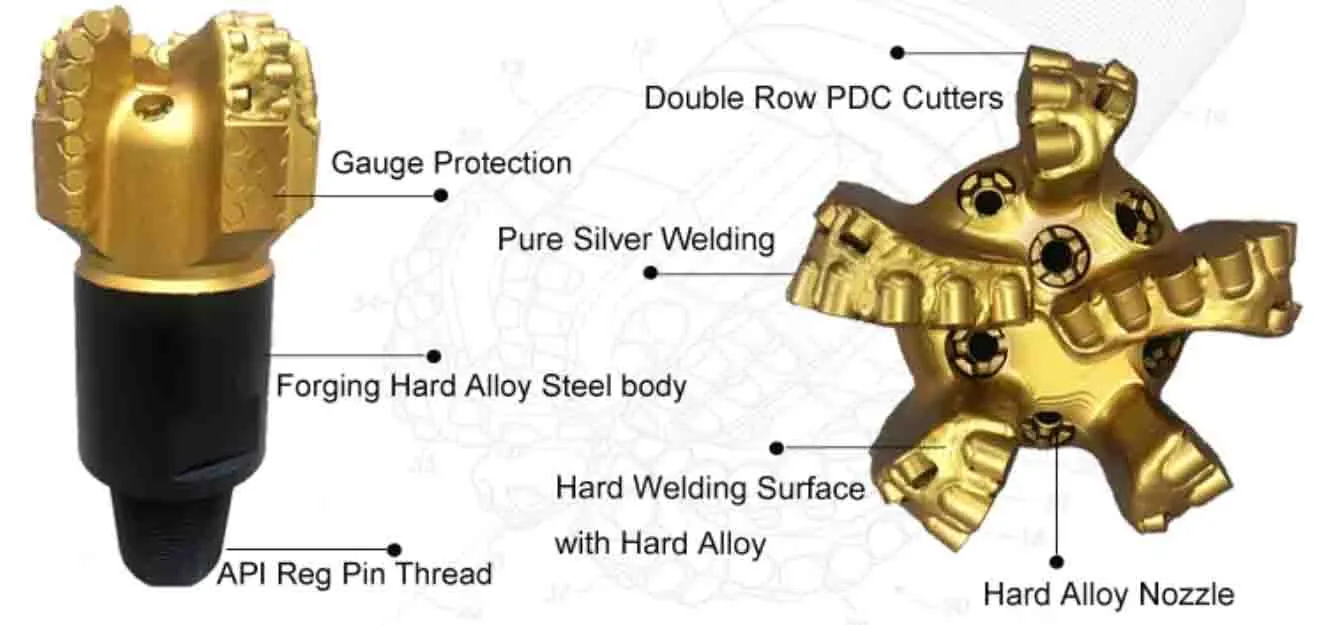

The number and measure of spouts in a 5-blade PDC bit are carefully calculated to accomplish the desired pressure-driven drive at the bit. Ordinarily, these bits highlight 3 to 5 spouts, with sizes extending from 9/32" to 14/32", depending on the particular application and required stream rates. This optimization guarantees satisfactory cleaning and cooling without over-the-top disintegration of the bit body or formation.

Hydraulic CFD Analysis

Advanced Computational Liquid Flow (CFD) investigation is frequently utilized in the design of 5-blade PDC bit power through pressure. This innovation permits engineers to visualize and optimize liquid stream designs around the bit, guaranteeing proficient cuttings expulsion and minimizing ranges of distribution that may lead to bit balling.

Enhanced Bit Cooling

The pressure-driven framework of a 5-blade PDC bit, not as it were helps in cuttings evacuation but also plays a pivotal part in bit cooling. The key situation of spouts guarantees that boring liquid comes to all basic ranges of the bit, avoiding overheating of the PDC cutters and extending bit life.

Conclusion

The highlights of a standard 5 Edges PDC Oil Bit speak to a summit of progressed design and viable field involvement. From the vital cutter format to the optimized edge tally and advanced power through pressure, each angle is carefully considered to maximize penetrating proficiency and bit life span. These bits offer an idealized adjust of soundness, forcefulness, and pressure-driven execution, making them perfect for a wide extend of penetrating applications in medium-hardness formations.

For oil and gas boring companies, oil benefit suppliers, and other substances included in penetrating operations, the 5 Edges PDC Oil Bit presents a flexible and high-performance arrangement. Its capacity to keep up tall ROP while guaranteeing borehole quality makes it an amazing choice for both vertical and directional boring projects.

At Shaanxi Hainaisen Petroleum Innovation Co., Ltd., we specialize in the inquiry about, advancement, and generation of top-quality PDC bore bits, including our progressed 5 Edges PDC Oil Bit. Our state-of-the-art 3,500m² office, prepared with 5-axis machining centers and CNC machine instruments, permits us to create bits that meet the most elevated industry standards. Our devoted R&D group is continuously prepared to work with you to customize bit plans that superbly coordinate your particular penetrating requirements.

Whether you're a huge oil benefits company looking for a long-term organization or a coal mining operation looking for a cost-effective boring arrangement, we have the ability and capabilities to meet your needs. Do not let imperfect penetrating devices hold back your operations. Reach out to us nowadays to find out how our 5 Edges PDC Oil Bits can revolutionize your penetrating proficiency and productivity.

FAQ

1. What are the main advantages of a 5-blade PDC Oil Bit?

The main advantages include enhanced cutting efficiency, improved stability, optimized hydraulics for better cuttings removal, increased ROP, and extended bit life. The 5-blade design offers a balance between aggressiveness and control, making it suitable for various formation types.

2. How does the cutter layout in a 5-blade PDC Oil Bit contribute to its performance?

The cutter layout in a 5-blade PDC Oil Bit is designed with a radial distribution and spiral arrangement. This optimizes cutting action, ensures even force distribution, reduces vibration, and improves cuttings evacuation, all contributing to enhanced drilling performance and bit longevity.

3. In what types of formations does a 5 Blades PDC Oil Bit perform best?

A 5-blade PDC Oil Bit performs exceptionally well in medium-hardness formations with low compressive strength. This includes formations such as shale, limestone, sandstone, and gypsum. The bit's design allows for efficient drilling in these formation types while maintaining stability and control.

4. How does the hydraulic system in a 5-blade PDC Oil Bit enhance its performance?

The hydraulic system in a 5-blade PDC Oil Bit is optimized through strategic nozzle placement and sizing. This ensures efficient cutting removal, adequate bit cooling, and even distribution of hydraulic energy across the bit face. Advanced CFD analysis is often used to fine-tune the hydraulics, resulting in improved overall drilling efficiency.

5 Blades PDC Oil Bit Manufacturers and Suppliers | HNS

Looking for a high-quality 5-blade PDC Oil Bit? Look no further than Shaanxi Hainaisen Petroleum Technology Co., Ltd. As a leading manufacturer and supplier in the industry, we offer top-notch products designed to meet the most demanding drilling requirements. Our expert team is ready to assist you in finding the perfect PDC bit solution for your specific needs. Whether you need standard bits or custom designs, we have you covered. Don't settle for less when it comes to your drilling operations. Contact us today at hainaisen@hnsdrillbit.com to discuss your requirements and experience the HNS difference in quality, performance, and customer service.

References

1. Smith, J.R. (2021). "Advanced PDC Bit Designs for Enhanced Drilling Efficiency." Journal of Petroleum Technology, 73(5), 42-48.

2. Johnson, A.L., et al. (2020). "Comparative Analysis of PDC Bit Blade Configurations in Medium Hardness Formations." SPE Drilling & Completion, 35(3), 301-315.

3. Chen, W., and Davis, K.L. (2019). "Hydraulic Optimization of PDC Bits Using Computational Fluid Dynamics." International Journal of Oil, Gas and Coal Technology, 22(4), 456-471.

4. Thompson, R.S. (2022). "Evolution of PDC Bit Cutter Layout Strategies for Improved Stability and ROP." Drilling Contractor Magazine, 78(2), 62-67.

5. Garcia, M.E., and Wilson, B.T. (2020). "Field Performance Comparison of 5-Blade vs. 6-Blade PDC Bits in Directional Drilling Applications." SPE/IADC Drilling Conference Proceedings, SPE-199642-MS.

6. Lefebvre, A., and Robinson, L.H. (2021). "Advancements in PDC Bit Design for Enhanced Durability in Abrasive Formations." Offshore Technology Conference Proceedings, OTC-30912-MS.