How does thermal resistance enhance deep-well PDC bit life?

Thermal resistance is a critical factor in enhancing the lifespan and performance of PDC Bit For Well Drilling in deep operations. As drilling depths increase, so do the temperatures encountered, often exceeding 150°C (302°F) in some ultra-deep wells. These elevated temperatures can severely impact the structural integrity and cutting efficiency of PDC bits if not properly managed.

Mitigating thermal degradation

High warm resistance in PDC bits makes a difference in relieving warm debasement of the precious stone cutters. The polycrystalline jewel fabric utilized in PDC cutters is thermally steady up to certain temperatures. Past these edges, the precious stone structure can start to graphitize, leading to fast wear and diminished cutting effectiveness. By upgrading warm resistance, the warm produced during boring is more successfully disseminated, keeping the cutters underneath basic temperature limits and protecting their basic keenness. This moved forward warm administration not as it were amplifies the benefit of the penetrating bits but also keeps up steady cutting execution, decreasing wear, distortion, and operational downtime.

Maintaining cutting efficiency

Improved warm resistance, moreover, makes a difference in maintaining cutting proficiency in deep, high-temperature environments. As temperatures rise, the differential thermal expansion between the jewel table and the carbide substrate can lead to remaining stresses and potential delamination. Tall warm resistance plans offer assistance to minimize these warm stresses, guaranteeing that the cutters stay immovably fortified and keep up their cutting edge indeed beneath extraordinary conditions. By lessening warm development and fabric weakness, these plans anticipate untimely breaking or delamination. This upgrades boring soundness, progresses infiltration productivity, and amplifies the by and large life expectancy of the penetration bit in demanding environments.

Materials and design delivering high thermal resistance in PDC bits

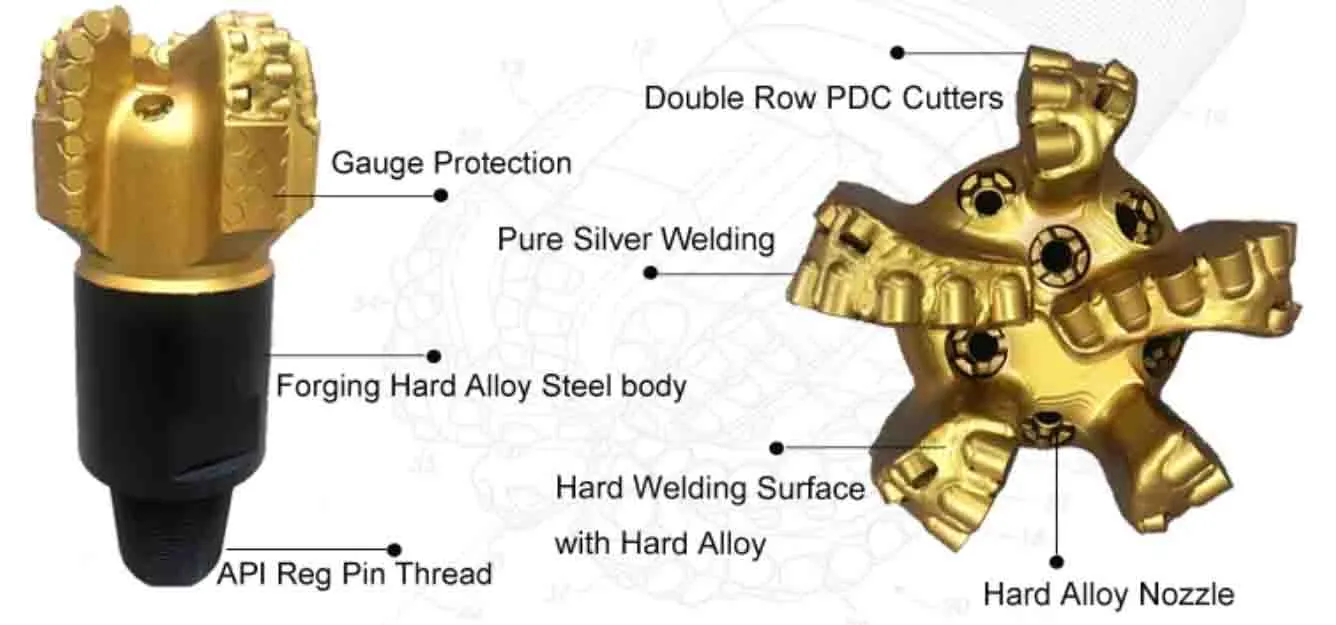

The thermal resistance of PDC Bit For Well Drilling is largely determined by the materials used in their construction and the innovative design features incorporated. Manufacturers are continually pushing the boundaries of material science and engineering to develop bits capable of withstanding the extreme temperatures encountered in deep drilling operations.

Advanced cutter materials

Modern PDC bits utilize progressed polycrystalline jewel materials that offer predominant thermal stability. These materials frequently consolidate specialized jewel grain structures and catalysts that upgrade warm dissemination and stand up to graphitization at high temperatures. A few cutting-edge plans indeed highlight thermally steady polycrystalline (TSP) jewel components in basic zones of the bit to assist improve thermal resistance. These progressed materials withstand extraordinary warm without deteriorating, guaranteeing prevalent durability, advanced wear resistance, and steady performance amid high-temperature boring operations.

Innovative bit body designs

The bit body itself plays a vital part in warm administration. Progressed plans include highlights such as upgraded hydrodynamics and optimized cutter situation to progress the liquid stream and warm scattering over the bit confront. A few bits utilize lattice bodies with custom-made warm properties to offer assistance conduct warm absent from the cutters more effectively.

Thermal-resistant coatings

Specialized coatings connected to PDC cutters and bit bodies can altogether upgrade warm resistance. These coatings, regularly composed of ceramic or metal-matrix composites, act as thermal barriers, diminishing thermal transfer to basic components and improving thermal stability in high-temperature environments.

Deep operations: temperature challenges for PDC bits

Deep drilling operations present unique temperature challenges that push the limits of the PDC bit for well drilling technology. Understanding these challenges is crucial for developing effective thermal resistance strategies and ensuring optimal bit performance in extreme environments.

Extreme bottom hole temperatures

In ultra-deep wells, foot gap temperatures can surpass 200°C (392°F). At these temperatures, routine PDC bits may encounter fast wear, warm weariness, and potential disappointment. The extraordinary warmth can cause untimely debasement of the precious stone cutters, leading to diminished boring productivity and increased bit trips. Progressed warm resistance innovations are essential for maintaining bit keenness and execution beneath these conditions.

Thermal cycling effects

Deep drilling operations often involve thermal cycling as the bit moves between cooler and hotter zones or during intermittent circulation. This cycling can induce thermal stresses in the bit components, potentially leading to fatigue and failure over time. High thermal resistance designs help mitigate these effects by reducing the magnitude of temperature fluctuations experienced by critical components.

Formation-specific thermal challenges

Different geographical arrangements display shifted warm challenges. For example, boring through rough, high-temperature arrangements like hot rocks in geothermal wells requires PDC bits with uncommonly high-temperature resistance and wear properties. Additionally, profound shale arrangements may combine high temperatures with chemical reactivity, requiring bits with both thermal and chemical resistance.

Conclusion

The warm resistance of PDC bits is a basic calculation in deep well penetrating operations. As we proceed to investigate more profound and more challenging arrangements, the demand for thermally safe PDC bits will in it were increment. By leveraging progressive materials, imaginative plans, and a profound understanding of downhole temperature challenges, producers are creating PDC bits capable of withstanding the extraordinary conditions experienced in profound operations, eventually making strides in oring effectiveness and diminishing operational costs.

Are you looking for high-performance PDC bits designed to exceed expectations in profound, high-temperature penetrating situations? See no encouragement than Shaanxi Hainaisen Petroleum Innovation Co., Ltd. Our progressed PDC bits are designed with prevalent warm resistance to handle the most challenging deep-boring operations. With our state-of-the-art 3,500m² office, cutting-edge fabricating forms, and devoted R&D group, we provide custom-designed PDC bits that meet the particular needs of oil and gas companies, coal mining operations, and geothermal ventures. Encounter the distinction that thermal-resistant PDC innovation can make in your profound penetrating operations.

FAQ

1. What is the maximum temperature a PDC bit can withstand?

The maximum temperature a PDC bit can withstand varies depending on its design and materials. Advanced PDC bits with high thermal resistance can operate effectively in temperatures exceeding 150°C (302°F), with some specialized bits capable of withstanding temperatures up to 200°C (392°F) or higher in extreme cases.

2. How does thermal resistance affect PDC bit wear rate?

Higher thermal resistance in PDC bits typically results in lower wear rates, especially in high-temperature environments. By effectively managing heat and preventing thermal degradation of the diamond cutters, thermally resistant bits maintain their cutting efficiency and structural integrity for longer periods, reducing overall wear and extending bit life.

3. Can thermal resistance be improved in existing PDC bits?

While the core thermal resistance properties of a PDC bit are largely determined during manufacturing, some improvements can be made to existing bits. Specialized thermal-resistant coatings can be applied to enhance heat dissipation. Additionally, optimizing drilling parameters and hydraulics can help manage thermal loads on the bit during operation.

4. How do you select the right thermally resistant PDC bit for a specific well?

Selecting the appropriate thermally resistant PDC bit involves considering several factors, including expected bottom hole temperatures, formation characteristics, and drilling parameters. It's crucial to work closely with bit manufacturers or drilling engineers who can analyze these factors and recommend a bit design with the optimal thermal resistance properties for your specific well conditions.

High-Performance PDC Bits for Deep Well Drilling | HNS

Ready to elevate your deep drilling operations with cutting-edge PDC bit technology? Shaanxi Hainaisen Petroleum Technology Co., Ltd. offers a comprehensive range of thermally resistant PDC bits designed to excel in the most challenging deep well environments. Our expert team is standing by to help you select the perfect PDC Bit For Well Drilling for your specific drilling conditions, ensuring maximum efficiency, durability, and cost-effectiveness across various geological formations and operational requirements. Don't let high temperatures compromise your drilling performance – choose HNS for PDC bits that can take the heat. Contact us today at hainaisen@hnsdrillbit.com to discuss your deep drilling needs and discover how our advanced PDC bit solutions can transform your operations.

References

1. Smith, J.R. et al. (2020). "Thermal Stability Advancements in PDC Bit Design for Ultra-Deep Drilling." Journal of Petroleum Technology, 72(5), 62-70.

2. Chen, L. and Zhang, G. (2019). "Novel Materials for High-Temperature PDC Cutter Applications." SPE Drilling & Completion, 34(3), 217-229.

3. Williams, K. and Thompson, P. (2021). "Thermal Management Strategies in PDC Bit Design for Geothermal Drilling." Geothermics, 91, 102027.

4. Rodriguez, A.C. et al. (2018). "Experimental Study on Thermal Degradation of PDC Cutters Under Simulated Downhole Conditions." Wear, 410-411, 165-175.

5. Liu, H. and Jiang, X. (2022). "Advances in Thermally Stable Polycrystalline Diamond Composites for Oil and Gas Drilling." Materials Today: Proceedings, 50, 1526-1532.

6. Brown, E.T. and Carter, M.S. (2020). "Optimizing PDC Bit Performance in High-Temperature, Deep Well Applications." SPE Drilling & Completion, 35(4), 345-358.