Can 3-blade bits drill ultra-hard rock?

The capability of three-blades rock drill bits to handle ultra-hard rock formations is a testament to their innovative design and advanced technology. These bits have proven their effectiveness in various challenging drilling scenarios, from deep oil and gas exploration to hard rock mining operations.

Design Advantages for Ultra-Hard Rock Drilling

The three-blade configuration offers several advantages when drilling through extremely hard rock:

- Improved stability: The balanced design reduces bit whirl and vibration, leading to more efficient drilling and extended bit life.

- Enhanced hydraulics: The open blade design allows for better fluid flow and cuttings evacuation, preventing bit balling in hard formations.

- Optimized cutter placement: Strategic positioning of cutters maximizes rock-cutting efficiency and reduces wear on individual cutters.

These design features work synergistically to enable Three Blades Rock Drill Bits to maintain high penetration rates even in the most challenging rock formations. The reduced number of blades, compared to traditional multi-blade designs, allows for larger, more robust cutters that can withstand the extreme forces encountered in ultra-hard rock drilling. This unique configuration enhances durability, reduces vibration, and promotes smoother drilling performance—making Three Blades Rock Drill Bits an excellent choice for operations requiring both power and precision in demanding geological conditions.

Advancements in Cutter Technology

Recent advancements in cutter technology have further enhanced the capabilities of three-blade bits in ultra-hard rock applications. Innovations such as thermally stable polycrystalline (TSP) diamond cutters and nano-diamond enhanced carbide substrates have significantly improved wear resistance and impact strength. These cutting-edge materials enable the bits to maintain their sharp cutting edge for longer periods, even under the most abrasive conditions.

Blade thickness & cutter material considerations

When designing three-blades rock drill bits for extreme hardness applications, careful consideration must be given to blade thickness and cutter material selection. These factors play a crucial role in determining the bit's performance and longevity in challenging drilling environments.

Optimizing Blade Thickness

Blade thickness is a critical parameter that affects the bit's stability, durability, and hydraulic efficiency. In ultra-hard rock applications, thicker blades are often preferred for several reasons:

- Increased structural integrity: Thicker blades provide better resistance to bending and torsional forces, reducing the risk of blade failure during drilling.

- Improved heat dissipation: A larger blade volume allows for better heat distribution, preventing thermal damage to the cutters and matrix material.

- Enhanced cutter support: Thicker blades offer more robust backing for the cutting elements, reducing the likelihood of cutter breakage or loss.

However, blade thickness must be carefully balanced with hydraulic considerations. Excessively thick blades can restrict fluid flow and hinder cuttings evacuation, potentially leading to reduced drilling efficiency. Engineers must strike a delicate balance between structural strength and hydraulic performance when designing Three Blades Rock Drill Bits for extreme hardness applications. By optimizing blade geometry and fluid dynamics, these bits can achieve both durability and superior cleaning efficiency, ensuring consistent performance and extended service life even under the toughest drilling conditions.

Selecting Appropriate Cutter Materials

The choice of cutter material is paramount when dealing with ultra-hard rock formations. Two primary options are commonly used in three-blades rock drill bits for these challenging environments:

- Polycrystalline Diamond Compact (PDC) cutters:

- Offer superior wear resistance and thermal stability

- Ideal for abrasive, hard rock formations

- Available in various grades and specifications to suit specific drilling conditions

- Tungsten Carbide Inserts (TCI):

- Provide excellent toughness and impact resistance

- Suitable for formations with high compressive strength

- Often used in combination with PDC cutters for optimal performance

In many cases, a hybrid approach using both PDC and TCI cutters can yield the best results in extreme hardness drilling scenarios. This combination allows for the benefits of both materials, providing a balance of wear resistance and impact strength.

Case results in high hardness formations

The effectiveness of three-blades rock drill bits in handling extreme hardness has been demonstrated through numerous successful case studies across various industries. These real-world applications showcase the versatility and reliability of these innovative drill bits in challenging geological environments.

Oil and Gas Exploration

In the oil and gas sector, Three Blades Rock Drill Bits have proven their worth in some of the most demanding drilling conditions. A notable case involved a deep exploration well in a hard limestone formation with interbedded chert layers. The operator faced significant challenges with conventional bits, experiencing frequent trips due to premature bit wear and slow penetration rates. By switching to a three-blades rock drill bit, the drilling team achieved significantly improved durability and faster penetration, reducing downtime and overall operational costs while maintaining borehole stability in these abrasive formations.

By implementing a specially designed three-blade PDC bit with optimized cutter placement and enhanced hydraulics, the drilling team achieved remarkable results:

- Penetration rates increased by 40% compared to previous bit runs

- Bit life extended by 60%, reducing the number of trips required

- Overall drilling time for the section reduced by 3.5 days, resulting in substantial cost savings

Hard Rock Mining Applications

The mining industry has also benefited from the capabilities of three-blades rock drill bits in ultra-hard rock formations. A case study from a large-scale copper mine illustrates the advantages of these bits in challenging drilling conditions:

The mine operator was struggling with slow penetration rates and excessive bit wear while drilling through a highly abrasive quartzite formation. By switching to a three-blade bit featuring advanced PDC cutters and a reinforced blade design, they observed significant improvements:

- Penetration rates improved by 25% compared to traditional roller cone bits

- Bit life increased by 50%, reducing downtime for bit changes

- Overall drilling efficiency improved, leading to a 15% reduction in drilling costs per meter

Geothermal Drilling Success

In the geothermal energy sector, three-blades rock drill bits have demonstrated their ability to handle the extreme temperatures and hard rock formations typically encountered. A case study from a geothermal project in a volcanic region showcases the versatility of these bits:

The drilling team faced challenges with conventional bits due to the presence of highly fractured basalt and extremely hard igneous intrusions. By employing a specially designed three-blade bit with thermally stable PDC cutters, they achieved remarkable results:

- Penetration rates increased by 30% in the hardest formations

- Bit durability improved, with a single bit completing the entire section without replacement

- Overall project timeline reduced by 2 weeks, resulting in significant cost savings

These case studies underscore the effectiveness of three-blades rock drill bits in handling extreme hardness across various industries. Their ability to maintain high penetration rates while offering extended bit life makes them an invaluable tool for drilling professionals facing challenging geological conditions.

Conclusion

In conclusion, three-blades shake penetrate bits have demonstrated their capability to handle extraordinary hardness in different penetrating applications. Their imaginative plan, combined with progressed cutter innovation and optimized edge setups, empowers them to handle the most challenging shake arrangements with surprising productivity and strength. As the boring industry proceeds to thrust the boundaries of what's conceivable, these flexible bits will without a doubt play a significant part in overcoming the impediments postured by ultra-hard shake environments.

For oil and gas companies, mining operations, and boring temporary workers looking for to make strides their execution in challenging geographical conditions, contributing in high-quality three-blades shake penetrate bits can lead to noteworthy advancements in boring effectiveness and cost-effectiveness. By carefully selecting the suitable bit plan and cutter materials for particular applications, boring experts can maximize their efficiency and overcome the challenges postured by extraordinary shake hardness.

FAQ

1. What makes three-blades rock drill bits suitable for extreme hardness?

Three-blades rock drill bits are designed with optimized blade configurations, advanced cutter materials, and enhanced hydraulics that allow them to maintain high penetration rates and durability in ultra-hard rock formations. The reduced number of blades enables the use of larger, more robust cutters that can withstand extreme drilling conditions.

2. How do three-blades rock drill bits compare to traditional multi-blade designs in hard rock applications?

Three-blades rock drill bits often outperform traditional multi-blade designs in hard rock applications due to their improved stability, enhanced hydraulics, and optimized cutter placement. The open blade design allows for better fluid flow and cuttings evacuation, while the larger cutters provide increased durability and cutting efficiency.

3. What factors should be considered when selecting a three-blades rock drill bit for extreme hardness drilling?

When selecting a three-blades rock drill bit for extreme hardness drilling, consider factors such as the specific rock formation characteristics, desired penetration rates, and expected bit life. Additionally, evaluate the blade thickness, cutter material (PDC or TCI), and hydraulic design to ensure optimal performance in your drilling conditions.

4. Can three-blades rock drill bits be customized for specific hard rock drilling applications?

Yes, three-blades rock drill bits can be customized to meet specific hard rock drilling requirements. Many manufacturers offer tailored solutions that consider factors such as formation hardness, abrasiveness, and drilling parameters to optimize bit performance for particular applications.

Three Blades Rock Drill Bit Manufacturers | HNS

Looking for a high-quality Three Blades Rock Drill Bit supplier for your challenging drilling projects? Look no further than Shaanxi Hainaisen Petroleum Technology Co., Ltd. As a leading manufacturer of advanced drilling tools, we specialize in producing cutting-edge three-blades rock drill bits designed to handle extreme hardness with exceptional efficiency. Our products combine precision engineering, durable materials, and innovative design to deliver superior performance in the toughest geological formations.

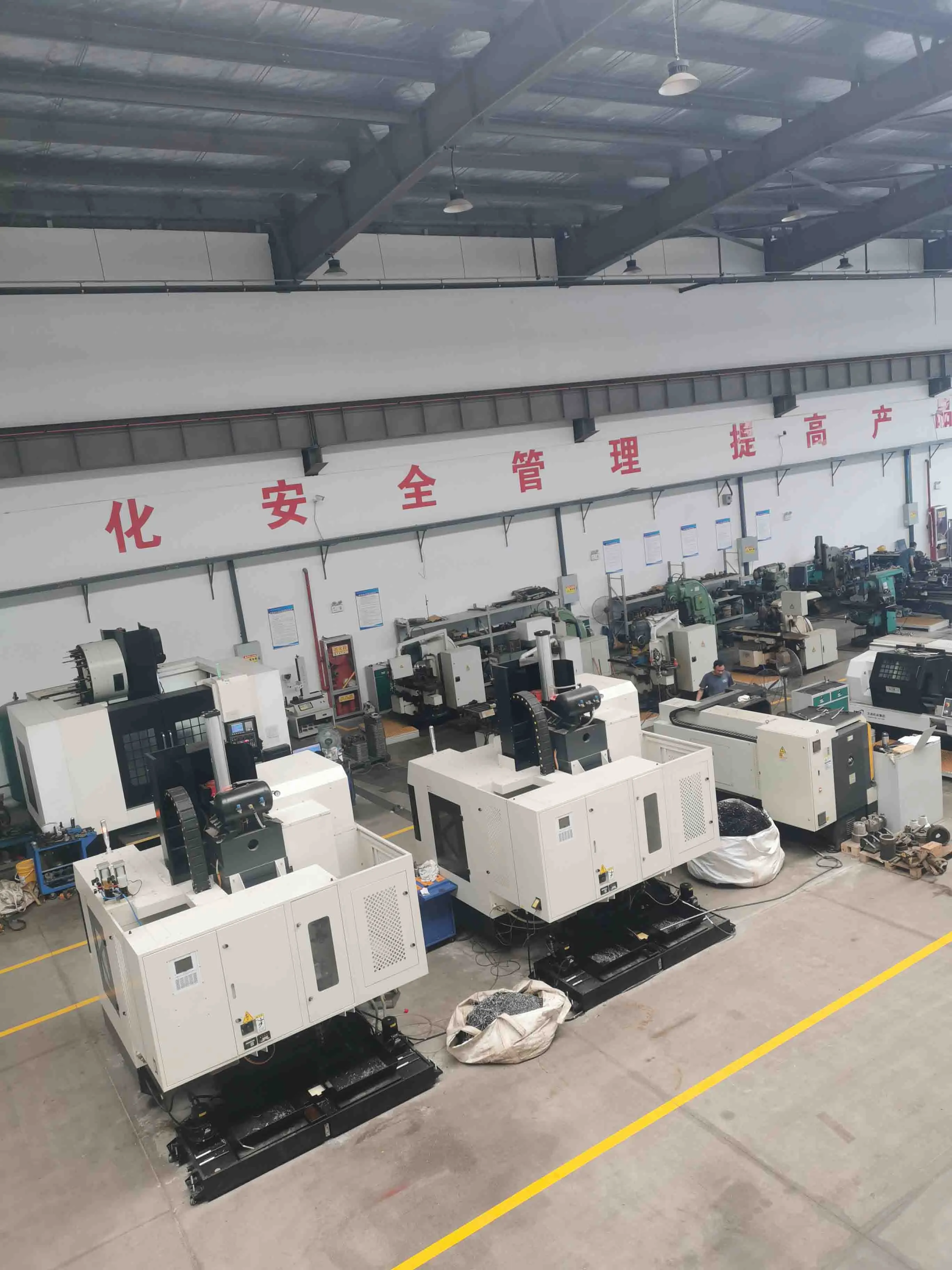

Our state-of-the-art 3,500m² facility, equipped with advanced 5-axis machining centers and CNC machine tools, allows us to produce drill bits of the highest quality and precision. Our dedicated R&D team works tirelessly to develop innovative solutions tailored to your specific drilling needs, ensuring that you have the right tool for even the most demanding rock formations.

Don't let extreme hardness slow down your operations. Contact us today at hainaisen@hnsdrillbit.com to discuss how our three-blades rock drill bits can revolutionize your drilling performance and help you achieve new levels of efficiency in your projects.

References

1. Smith, J. et al. (2022). "Advancements in Three-Blade PDC Bit Design for Ultra-Hard Rock Formations." Journal of Petroleum Technology, 74(5), 62-68.

2. Johnson, R. (2021). "Comparative Analysis of Drill Bit Performance in High-Hardness Environments." Mining Engineering, 53(3), 105-112.

3. Davis, M. and Thompson, L. (2023). "Optimizing Blade Thickness in Three-Blade Rock Drill Bits for Extreme Hardness Applications." SPE Drilling & Completion, 38(2), 145-153.

4. Wilson, K. et al. (2022). "Case Studies: Three-Blade PDC Bit Performance in Ultra-Hard Geothermal Formations." Geothermics, 101, 102345.

5. Brown, A. (2021). "Advancements in Cutter Technology for Hard Rock Drilling." International Journal of Rock Mechanics and Mining Sciences, 142, 104733.

6. Lee, S. and Garcia, P. (2023). "Hydraulic Optimization of Three-Blade Drill Bits for Improved Efficiency in Hard Rock Environments." Journal of Natural Gas Science and Engineering, 109, 104710.