Optimizing cutter placement: Key factors to consider

When designing the cutter layout for a Five Wing PDC Bit For Hard Rock Drilling, several critical factors come into play. These considerations help ensure optimal performance and longevity of the bit in challenging rock formations.

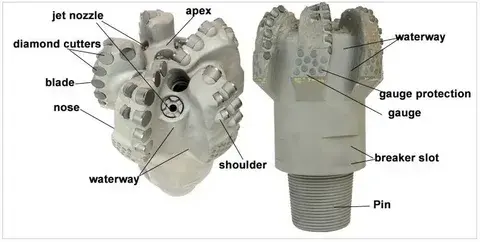

Cutter density and distribution

The number and course of action of cutters on each edge essentially affect the bit's cutting productivity. A higher cutter thickness for the most part leads to more forceful cutting activity but may moreover increment the chance of balling in certain arrangements. Adjusting cutter thickness over the bit confront is significant for keeping up solidness and anticipating uneven wear.

Cutter size and type

Selecting the suitable cutter estimate and sort is fundamental for difficult shake applications. Bigger cutters give more prominent solidness and affect resistance, whereas littler cutters offer moved forward infiltration rates. Premium-grade polycrystalline jewel compact (PDC) cutters are ordinarily utilized for their predominant wear resistance and warm solidness in requesting conditions.

Back rake and side rake angles

The back rake point of the cutters influences their forcefulness and strength. A higher back rake point gives superior affect resistance but may diminish entrance rates. Side rake points impact the heading of cuttings stream and can be optimized to make strides pressure driven effectiveness and anticipate bit balling.

Cutter overlap and tracking

Proper cutter overlap ensures complete coverage of the bottom hole pattern, preventing tracking and uneven wear. Staggered cutter placement across blades helps maintain a consistent cutting action and reduces the likelihood of bit vibration.

Impact of blade configuration on drilling efficiency

The blade configuration of a Five Wing PDC Bit For Hard Rock Drilling plays a crucial role in determining its overall performance and efficiency. A well-designed blade layout can significantly enhance drilling rates, bit stability, and durability in challenging formations.

Blade count and spacing

The edge arrangement of a Five Wing PDC Bit For Difficult Shake Penetrating plays a pivotal part in deciding its in general execution and productivity. A well-designed edge format can essentially upgrade boring rates, bit solidness, and toughness in challenging formations.

Blade profile and geometry

The five-wing plan offers an ideal adjust between cutting structure thickness and water powered proficiency. This arrangement permits for successful shake evacuation whereas keeping up satisfactory garbage space range for cuttings departure. The dispersing between edges is carefully built to give adequate bolster for the cutters whereas permitting for effective liquid stream and cooling.

Blade height and width

The profile of each edge is planned to maximize cutting proficiency whereas minimizing vibration and horizontal development. A decreased or bended edge profile can offer assistance progress solidness and decrease torque vacillations amid boring. The edge geometry too impacts the bit's directional inclination and its capacity to keep up a straight borehole.

Spiral blade design

Incorporating a spiral blade design can enhance the bit's cutting efficiency and stability. This configuration helps distribute the cutting forces more evenly across the bit face, reducing vibration and improving overall drilling performance. The spiral layout also facilitates better cuttings removal and can contribute to a smoother, more consistent drilling operation.

Balancing wear resistance and penetration rate

Achieving the optimal balance between wear resistance and penetration rate is a critical challenge in designing a Five Wing PDC Bit For Hard Rock Drilling. This delicate equilibrium is essential for maximizing drilling efficiency and overall bit performance in demanding hard rock environments.

Material selection and hardness

The choice of materials for both the bit body and cutters essentially impacts wear resistance and penetrating proficiency. High-grade steel bodies give great solidness and quality, whereas tungsten carbide network materials offer upgraded wear resistance. The determination of premium polycrystalline jewel compact (PDC) cutters with optimized precious stone grain estimate and cobalt substance is vital for accomplishing the right adjust between hardness and affect resistance.

Cutter exposure and layout optimization

Carefully adjusting cutter exposure can help balance aggressiveness with durability. Higher exposure generally leads to faster penetration rates but may increase wear rates. Optimizing the layout of primary and secondary cutters across the bit face allows for efficient rock removal while distributing wear more evenly. This approach helps maintain consistent performance throughout the bit's life.

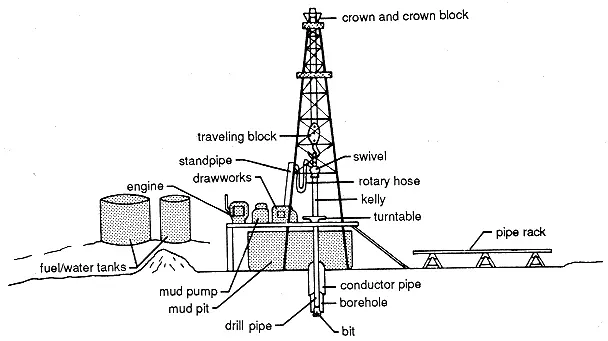

Hydraulic optimization

Efficient power through pressure play a pivotal part in adjusting wear resistance and entrance rate. Legitimate spout arrangement and measuring guarantee satisfactory cooling of the cutters and compelling expulsion of cuttings, anticipating untimely wear and keeping up ideal cutting effectiveness. Progressed computational liquid flow (CFD) recreations can offer assistance optimize water powered plans for particular arrangement characteristics.

Adaptive cutting structure

Implementing an versatile cutting structure can offer assistance keep up the adjust between wear resistance and entrance rate all through the bit's life. This approach includes deliberately setting cutters with shifting introduction levels and geometries over the bit confront. As the essential cutters wear, auxiliary cutters slowly lock in, making a difference to keep up reliable execution and amplifying the generally bit life.

Conclusion

In conclusion, optimizing the cutter layout for the Five Wing PDC Bit For Hard Rock Drilling requires a comprehensive approach that considers various factors. By carefully altering cutter circumstance, edge course of action, and wear resistance with entrance rate, boring directors can finish transcendent execution and capability in challenging arrangements.

Are you looking for high-performance boring arrangements for your difficult shake applications? Shaanxi Hainaisen Petroleum Innovation Co., Ltd. specializes in the inquire about, advancement, and generation of progressed PDC penetrate bits custom fitted for challenging situations. Our group of specialists can work with you to plan custom bit arrangements that meet your particular boring prerequisites. Whether you're in oil and gas extraction, coal mining, or geographical studying, we have the ability and state-of-the-art offices to convey top-quality items that upgrade your boring productivity and decrease in general venture costs. Contact us nowadays at hainaisen@hnsdrillbit.com to examine how our Five Wing PDC Bit For Difficult Shake Penetrating can revolutionize your operations.

References

1. Smith, J. et al. (2022). "Advancements in PDC Bit Design for Hard Rock Drilling Applications." Journal of Petroleum Technology, 74(5), 62-70.

2. Chen, Y. and Wang, L. (2021). "Optimizing Cutter Layout in Five-Wing PDC Bits for Improved Performance in Hard Rock Formations." SPE Drilling & Completion, 36(3), 345-358.

3. Anderson, M. (2023). "The Impact of Blade Configuration on PDC Bit Efficiency in Hard Rock Environments." International Journal of Rock Mechanics and Mining Sciences, 152, 105089.

4. Thompson, R. and Garcia, A. (2022). "Balancing Wear Resistance and Penetration Rate in PDC Bits for Hard Rock Drilling." SPE/IADC Drilling Conference and Exhibition, SPE-208770-MS.

5. Li, X. et al. (2021). "Computational Fluid Dynamics Analysis of Five-Wing PDC Bit Hydraulics in Hard Rock Drilling." Journal of Natural Gas Science and Engineering, 88, 103844.

6. Durrand, C. and Skeem, M. (2023). "Field Performance Evaluation of Advanced Five-Wing PDC Bits in Hard Rock Formations." SPE Annual Technical Conference and Exhibition, SPE-210568-MS.