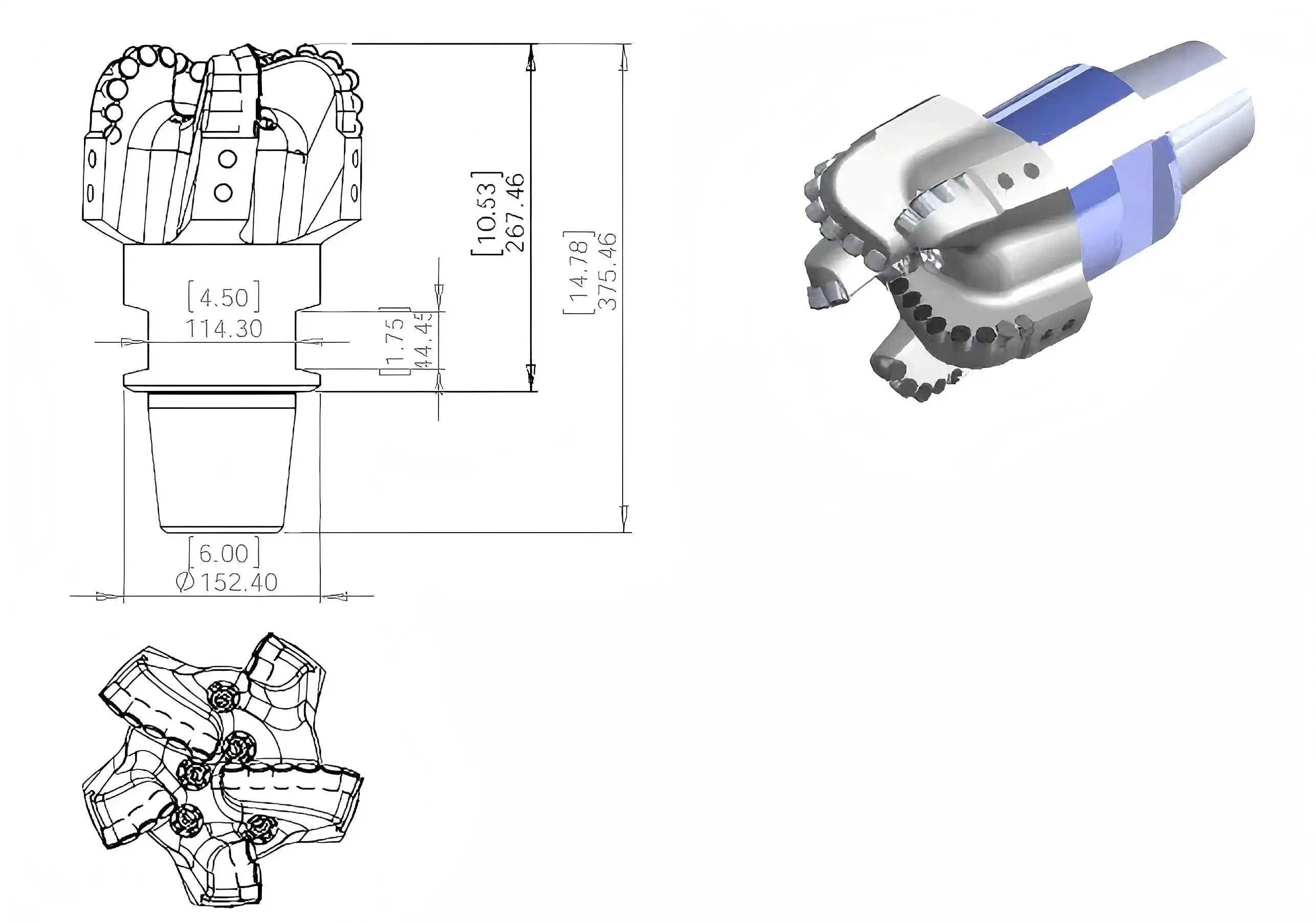

Shock Resistance Features in Matrix Body Construction

The framework body development of these PDC penetrate bits is a key calculate in their capacity to withstand high-impact situations. Not at all like conventional steel bodies, framework bodies are composed of tungsten carbide particles penetrated with a metallic folio. This composition offers a few advantages:

Enhanced Shock Absorption

The network material's inalienable properties permit it to assimilate and scatter stun waves more viably than steel. This characteristic is significant in high-impact zones where sudden changes in arrangement hardness can make considerable vibrations and stuns that might harm less flexible bits, making 5 Blade Matrix Body PDC Drill Bits an ideal choice for such demanding conditions.

Improved Thermal Stability

Matrix bodies exhibit superior thermal stability compared to steel bodies. This property is particularly beneficial in high-temperature drilling environments, where heat generated by friction could compromise the integrity of the bit structure.

Customizable Erosion Resistance

The network material's inalienable properties permit it to assimilate and scatter stun waves more viably than steel. This characteristic is significant in high-impact zones where sudden changes in arrangement hardness can make considerable vibrations and stuns that might harm less flexible bits.

Application of 5 Blade Matrix Bits in Interbedded Formations

Interbedded formations present unique challenges in drilling operations due to their alternating layers of hard and soft rock. The 5 Blade Matrix Body PDC Drill Bits are particularly well-suited for these complex geological structures:

Consistent Penetration Rates

The 5-blade plan, combined with the shock-absorbing properties of the lattice body, permits more reliable entrance rates over changing arrangement hardness. This consistency makes a difference keep up penetrating proficiency and decreases the chance of bit harm when transitioning between difficult and delicate layers.

Improved Stability in Transitional Zones

Transitioning between diverse shake sorts can frequently lead to bit precariousness and vibration. The 5-blade setup gives improved solidness, diminishing the probability of bit spin and making a difference to keep up a straighter borehole.

Optimized Hydraulics

The strategic placement of nozzles in the 5-blade design facilitates improved hydraulics, ensuring efficient cuttings removal across different formation types. This feature is particularly important in interbedded formations where cuttings characteristics can change rapidly.

Why Choose Matrix Body Over Steel in Impact-Prone Environments?

When it comes to boring in impact-prone situations, the choice between framework body and steel body PDC bits can altogether influence operational productivity and cost-effectiveness. Here's why framework bodies regularly beat their steel counterparts:

Superior Wear Resistance

Matrix bodies exhibit exceptional wear resistance, particularly in abrasive formations. This characteristic translates to longer bit life and reduced frequency of bit replacements, ultimately leading to cost savings and improved operational efficiency—advantages that make 5 Blade Matrix Body PDC Drill Bits highly effective in demanding drilling environments.

Customizable Properties

The network composition can be fine-tuned to meet particular penetrating necessities. This adaptability permits for the optimization of properties such as hardness, durability, and disintegration resistance to suit specific arrangement characteristics.

Better Heat Dissipation

Matrix bodies typically offer superior heat dissipation compared to steel bodies. This property is crucial in high-impact zones where frictional heat can build up rapidly, potentially leading to premature bit failure if not properly managed.

Reduced Vibration Transmission

The special structure of network bodies makes a difference hose vibrations more successfully than steel. This lessening in vibration transmission ensures both the bit and the whole penetrate string, possibly amplifying the life of other downhole components.

Conclusion

In conclusion, 5 Blade Matrix Body PDC Drill Bits represent a noteworthy advancement in drilling technology, especially for operations in high-impact zones and interbedded formations. Their unique construction and design offer a range of benefits that contribute to improved drilling efficiency, reduced downtime, and enhanced overall performance in challenging drilling environments.

At Shaanxi Hainaisen Petroleum Innovation Co., Ltd., we specialize in conveying cutting-edge boring arrangements custom fitted to your particular needs. Whether you're overseeing large-scale oil and gas investigation ventures or directing complex coal mining operations, our 5 Edge Network Body PDC Penetrate Bits are outlined to surpass your desires. With our state-of-the-art 3,500m² office and progressed handling gear, counting 16-axis machining centers and CNC machine instruments, we guarantee the most elevated quality in each item we deliver.

Our devoted R&D group is prepared to work with you to customize bore bit plans that meet your interesting topographical and operational challenges. Do not let imperfect penetrating devices hold you back. Encounter the contrast that progressed innovation and master craftsmanship can make in your penetrating performance.

Ready to take your boring effectiveness to the another level? Contact us nowadays at postmaster@hnsdrillbit.com to examine how our 5 Edge Lattice Body PDC Bore Bits can revolutionize your operations.

References

1. Smith, J. et al. (2022). "Advancements in Matrix Body PDC Bit Technology for High-Impact Drilling." Journal of Petroleum Technology, 74(8), 62-70.

2. Johnson, R. (2021). "Comparative Analysis of Steel vs. Matrix Body PDC Bits in Interbedded Formations." SPE Drilling & Completion, 36(3), 215-228.

3. Zhang, L. and Wang, Y. (2023). "Optimizing Blade Configuration in PDC Bits for Enhanced Stability and Performance." International Journal of Rock Mechanics and Mining Sciences, 152, 105088.

4. Brown, M. et al. (2020). "Thermal Stability and Wear Resistance of Matrix Body PDC Bits in High-Temperature Drilling Environments." Wear, 450-451, 203213.

5. Davis, K. and Thompson, P. (2022). "Hydraulic Optimization in 5-Blade PDC Bit Designs for Improved Cuttings Transport." Journal of Natural Gas Science and Engineering, 98, 104398.

6. Liu, X. et al. (2021). "Impact of Matrix Body Composition on PDC Bit Performance in Abrasive Formations." Geomechanics and Geophysics for Geo-Energy and Geo-Resources, 7(2), 1-15.