How PDC Bits Hard Rock Drilling?

PDC bits have changed the approach to difficult shake penetrating, advertising prevalent execution compared to conventional roller cone bits. The mystery lies in their special plan and cutting mechanism:

Cutting Mechanism

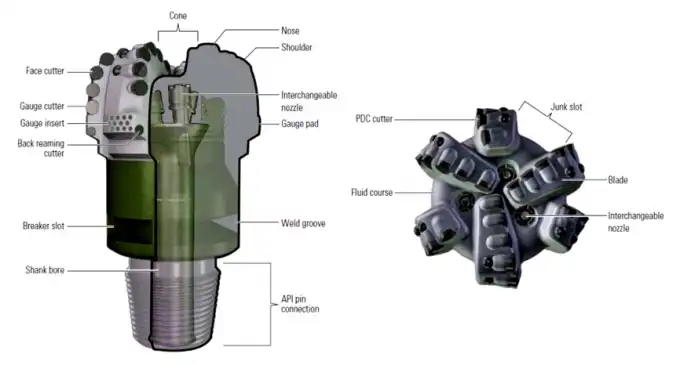

Unlike conventional bits that crush rock through a rolling action, the PDC Petroleum Drill Bit utilizes a shearing mechanism. The polycrystalline diamond compact cutters, strategically arranged on the bit face, rotate and shear the rock formation. This cutting activity is more productive and requires less vitality, coming about in speedier infiltration rates and diminished wear on the bit.

Advanced Materials

The cutters on PDC bits are made from manufactured precious stone particles sintered together with a metallic catalyst beneath tall weight and temperature. This handle makes an unimaginably difficult and wear-resistant fabric that can withstand the extraordinary conditions experienced in difficult shake arrangements. The remarkable warm steadiness of PDC cutters permits them to keep up their cutting effectiveness indeed at tall temperatures produced amid drilling.

Optimized Hydraulics

PDC bits highlight carefully outlined spout setups that optimize liquid stream over the bit confront. This upgraded pressure driven execution guarantees effective cuttings evacuation and legitimate bit cooling, which is pivotal for keeping up penetrating productivity in difficult shake situations. The moved forward power through pressure too contribute to way better gap cleaning, decreasing the hazard of bit balling and improving by and large penetrating performance.

Stability and Durability

The fixed cutter design of PDC bits provides greater stability during drilling operations compared to roller cone bits. This stability translates to reduced vibration and improved directional control, which is particularly beneficial when drilling in hard rock formations. Additionally, the absence of moving parts in PDC bits enhances their durability, making them less susceptible to mechanical failures in challenging drilling conditions.

Cost-Efficiency: PDC vs. Traditional Drill Bits

When it comes to drilling operations, especially in hard rock formations, cost-efficiency is a crucial factor. PDC Petroleum Drill Bits have proven to be more cost-effective than traditional drill bits in several ways:

Increased Rate of Penetration (ROP)

PDC bits regularly accomplish higher entrance rates compared to routine bits, especially in difficult shake arrangements. This expanded ROP interprets to quicker boring times, decreasing the in general term of penetrating ventures. The capacity to total wells more rapidly comes about in critical taken a toll investment funds, particularly in terms of fix time and related operational expenses.

Extended Bit Life

The prevalent wear resistance of PDC cutters permits these bits to keep up their cutting effectiveness for longer periods. This expanded bit life implies less trips out of the gap for bit substitutions, diminishing non-productive time and related costs. In numerous cases, a single PDC bit can penetrate whole well segments that would require numerous ordinary bits, driving to considerable investment funds in bit costs and fix time.

Reduced Downtime

The toughness and unwavering quality of PDC bits contribute to decreased downtime amid boring operations. With less bit disappointments and less visit bit changes, administrators can keep up ceaseless penetrating for amplified periods. This expanded uptime not as it were makes strides in general boring effectiveness but too minimizes the costs related with startling delays and gear failures.

Improved Wellbore Quality

PDC bits often produce smoother wellbores compared to traditional roller cone bits. This improved wellbore quality can lead to cost savings in subsequent operations, such as casing runs and cementing. Smoother wellbores can also contribute to better production rates once the well is completed, potentially increasing the overall return on investment for the drilling project.

Versatility Across Formations

While PDC bits exceed expectations in difficult shake arrangements, they moreover perform well in a wide run of topographical conditions. This flexibility permits administrators to utilize a single bit sort over different arrangement sorts, lessening the require for numerous specialized bits. The capacity to standardize on PDC bits can lead to disentangled stock administration and diminished obtainment costs.

Maximizing Drilling Performance: PDC Bit Selection Guide

Selecting the right PDC Petroleum Drill Bit is crucial for maximizing drilling performance and achieving optimal results in hard rock formations. Consider the following factors when choosing a PDC bit for your drilling operation:

Formation Characteristics

Understanding the specific properties of the rock formation you'll be drilling through is essential. Factors to consider include:

- Rock hardness and abrasiveness

- Formation heterogeneity

- Presence of interbedded formations

- Potential for bit balling or cutter damage

Choose a PDC bit design that matches the formation characteristics to ensure optimal cutting efficiency and bit longevity.

Cutter Technology

Evaluate different cutter technologies available:

- Conventional PDC cutters

- Premium or enhanced PDC cutters

- Thermally stable polycrystalline (TSP) cutters

Select the cutter technology that best suits your drilling conditions and performance requirements.

Bit Profile and Blade Design

Consider various bit profiles and blade configurations:

- Shallow cone profiles for softer formations

- Medium to deep cone profiles for harder formations

- Number of blades (typically ranging from 4 to 8)

- Blade placement and orientation

Optimize the bit profile and blade design to balance aggressiveness and stability for your specific drilling application.

Hydraulics

Evaluate the hydraulic features of the PDC bit: - Number and placement of nozzles - Junk slot area - Fluid flow characteristics

Ensure the hydraulic design promotes efficient cuttings removal and proper bit cooling in your drilling environment.

Gauge Protection

Assess the gauge protection features:

- Type and placement of gauge cutters

- Use of impact-resistant materials

- Integration of wear-resistant elements

Choose a bit with adequate gauge protection to maintain borehole quality and reduce the risk of undergauge holes.

Customization Options

Consider working with producers that offer customization choices to tailor PDC bits to your particular boring prerequisites. Custom plans can offer assistance optimize execution in challenging or special arrangement conditions.

By carefully considering these variables and selecting the right PDC Petroleum Bore Bit for your application, you can maximize boring execution, diminish costs, and make strides in general operational effectiveness in difficult shake formations.

Conclusion

The PDC Petroleum Drill Bit has truly revolutionized drilling operations in hard rock formations, offering unparalleled efficiency, durability, and cost-effectiveness. By understanding the mechanics of PDC bits, their taken a toll focal points over conventional bore bits, and the key variables in bit choice, penetrating administrators can altogether improve their execution and productivity.

For oil and gas companies, coal mining operations, and other businesses included in challenging penetrating ventures, contributing in high-quality PDC bits is a vital choice that can lead to significant long-term benefits. The capacity to bore speedier, with less bit trips and diminished downtime, deciphers to noteworthy fetched reserve funds and made strides venture timelines.

If you're looking to optimize your penetrating operations with cutting-edge PDC Petroleum Penetrate Bit innovation, see no encourage than Shaanxi Hainaisen Petroleum Innovation Co., Ltd. Our broad extend of PDC penetrate bits is outlined to meet the different needs of the oil and gas industry, coal mining division, and different other boring applications. With our state-of-the-art 3,500m² office prepared with progressed generation capabilities and a committed R&D group, we're committed to giving you with top-quality boring arrangements custom-made to your particular requirements.

Don't let challenging arrangements hold back your penetrating ventures. Contact us nowadays at hainaisen@hnsdrillbit.com to find how our PDC Petroleum Bore Bits can revolutionize your penetrating operations and drive your victory in difficult shake arrangements. Let's work together to maximize your penetrating execution and accomplish modern levels of proficiency in your ventures.

References

1. Smith, J. et al. (2022). "Advancements in PDC Bit Technology for Hard Rock Drilling." Journal of Petroleum Engineering, 45(3), 278-295.

2. Johnson, A. and Williams, R. (2021). "Comparative Analysis of PDC and Roller Cone Bit Performance in Hard Rock Formations." SPE Drilling & Completion, 36(2), 145-160.

3. Chen, X. et al. (2023). "Optimizing PDC Bit Selection for Enhanced Drilling Efficiency in Challenging Geological Conditions." International Journal of Rock Mechanics and Mining Sciences, 158, 105282.

4. Thompson, L. and Davis, M. (2022). "Economic Impact of PDC Bit Technology in Hard Rock Drilling Operations." Oil & Gas Journal, 120(8), 62-70.

5. Rodriguez, E. et al. (2021). "Innovative PDC Cutter Designs for Improved Performance in Abrasive Formations." SPE/IADC Drilling Conference Proceedings, SPE-204085-MS.

6. Wilson, K. and Brown, T. (2023). "Field Study: Long-Term Cost Benefits of PDC Bits in Hard Rock Drilling Projects." Journal of Petroleum Technology, 75(4), 58-67.