Steel Body vs. Matrix PDC Bits: Which is Best for Hard Rock?

When drilling in hard rock, the choice between steel body and matrix PDC bits can have a big effect on how well the drilling goes and how well the project turns out as a whole. While both types of bits have their good points, steel body PDC bits tend to do better than matrix bits in tough forms.

Advantages of Steel Body PDC Bits in Hard Rock Drilling

Steel body PDC bits offer several advantages that make them particularly well-suited for hard rock applications:

- Enhanced Durability: The robust steel body construction provides superior strength and impact resistance, crucial for withstanding the harsh conditions encountered in hard rock formations.

- Improved Heat Dissipation: Steel's higher thermal conductivity allows for better heat dissipation during drilling, reducing the risk of thermal degradation of the PDC cutters.

- Greater Flexibility in Design: Steel bodies allow for more complex and optimized blade designs, enabling engineers to create configurations that maximize cutting efficiency and stability in hard rock.

- Easier Repair and Maintenance: In the event of damage, steel body bits are often easier to repair or refurbish compared to matrix bits, potentially extending their usable life.

Limitations of Matrix PDC Bits in Hard Rock

While matrix PDC bits have their place in the drilling industry, they may face challenges in hard rock environments:

- Increased Brittleness: The tungsten carbide matrix material, while hard, can be more brittle than steel, making it more susceptible to cracking or chipping in high-impact hard rock drilling.

- Limited Design Flexibility: The manufacturing process for matrix bits can restrict certain design features that might be beneficial for hard rock drilling.

- Potential for Erosion: In abrasive hard rock formations, the matrix material may erode more quickly than steel, potentially leading to premature bit failure.

In the end, both types of bits have their good points, but the Three Blades Steel Body PDC Bit is usually the better choice for hard rock drilling jobs because it lasts longer, can be designed in different ways, and works better overall in tough formations.

Why Three-Blade PDC Bits Provide Better Stability in Tough Formations?

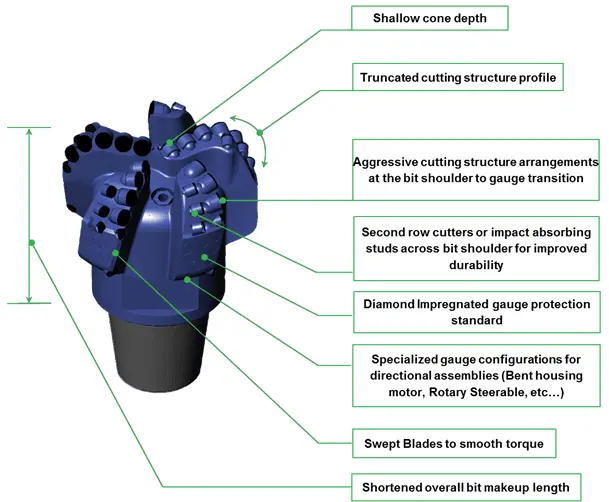

When it comes to drilling through tough formations, the three-blade design of PDC bits has changed the game. They are more stable and work better than standard bits. This new way of designing bits solves a number of important problems that come up when digging in tough conditions.

Optimal Weight Distribution and Balance

One of the best things about the three-blade shape is that it better distributes and balances weight. The blades are arranged symmetrically around the bit body, which makes sure that the pressures are spread out evenly during drilling. This balanced setup reduces bit whirl and lateral vibrations, which are common problems in tough formations and can cause bits to wear out faster and dig less efficiently.

Improved Hydraulics and Cuttings Evacuation

The three-blade layout creates larger junk slots between the blades, allowing for improved hydraulics and more efficient cuttings evacuation. This enhanced fluid flow helps to:

- Prevent bit balling in sticky formations

- Reduce the risk of bottom hole assembly (BHA) sticking

- Maintain consistent cooling of the PDC cutters

- Facilitate faster penetration rates by quickly removing drilled material

Reduced Torque Fluctuations

The Three Blades Steel Body PDC Bit design helps to keep drilling pressure changes to a minimum. The blades are evenly spaced so they engage with the rock more consistently. This makes the process go more smoothly and puts less stress on the drill string. This steadiness is especially helpful when drilling in a certain direction, where keeping the toolface orientation steady is very important.

Enhanced Steerability in Directional Drilling

For directional drilling operations in tough formations, the three-blade configuration offers improved steerability. The reduced lateral forces and more predictable behavior of the bit allow for better control and more accurate wellbore trajectories. This enhanced directional control can lead to:

- More precise well placement

- Reduced dogleg severity

- Improved overall wellbore quality

By providing better stability in tough formations, the Three Blades Steel Body PDC Bit three-blade PDC bit design enables operators to achieve higher rates of penetration, extended bit life, and improved overall drilling performance in challenging environments.

How Steel Body Construction Extends PDC Bit Lifespan?

The steel body design of PDC bits is a key factor in making them last longer, especially when they are used for hard rock drilling. This strong design has a number of important benefits that make it last longer and keep working well over time.

Superior Impact Resistance

Steel is naturally tough and flexible, which makes it very resistant to the impact forces that are used in drills. This toughness comes in handy when cutting through different types of rock or when unexpectedly running into hard stringers. The steel body absorbs and spreads shock loads better than flimsy materials, which lowers the risk of catastrophic failure and makes the bit last longer.

Enhanced Thermal Management

The thermal properties of Three Blades Steel Body PDC Bit steel contribute significantly to the longevity of PDC bits. Steel's higher thermal conductivity compared to matrix materials allows for more efficient heat dissipation during drilling. This improved heat management helps to:

- Prevent thermal degradation of PDC cutters

- Maintain optimal cutting efficiency over extended periods

- Reduce the risk of premature cutter failure due to overheating

Structural Integrity Under High Loads

The Steel Body PDC Bit construction provides excellent structural integrity under the high loads experienced in hard rock drilling. This robust framework ensures that:

- Blade stability is maintained throughout the drilling process

- Cutter pockets remain secure, preventing cutter loss or movement

- The overall bit geometry remains consistent, preserving drilling efficiency

Erosion Resistance in Abrasive Environments

Even though nothing is completely resistant to wear and tear, Three Blades Steel Body PDC When it comes to mechanical wear, bit steel bodies usually hold up better than some matrix materials. This better resistance to erosion helps keep the bit's gauge and general structure, which helps it work consistently and last longer in tough drilling conditions.

Customization and Repair Potential

Because the body is made of steel, bit design and customization are more flexible. Because it is flexible, makers can find the best blade profiles, cutter placements, and hydraulic channels for each type of formation. Also, steel body bits are often easier to fix or refurbish, which extends their useful life and saves users money.

Steel body design gives PDC bits these benefits, which can help them last a lot longer, especially when drilling in hard rock. This longer durability means less time spent tripping, less money spent on bit replacement, and better total drilling efficiency for operators working in tough formations.

Conclusion

One big step forward in hard rock drilling technology is the Three Blades Steel Body PDC Bit, which is very stable, lasts a long time, and works very well. This bit solves many of the problems that come with drilling in tough rocks by using the benefits of both the steel body construction and the unique three-blade design. This bit's design includes better weight distribution, better hydraulics, better impact protection, and better thermal management. All of these features make the bit work better and last longer.

If a drilling operator has to work in hard rock, the bit they use can make a big difference in how the job turns out. There is a great option called the Three Blades Steel Body PDC Bit that can help with faster penetration rates, less downtime, and, in the end, cheaper drilling operations.

Do you want to get the most out of your hard rock drilling? Our high-performance Three Blades Steel Body PDC Bit is made by Shaanxi Hainaisen Petroleum Technology Co., Ltd., a company that focuses on researching, developing, and making high-tech drilling tools. Our 3,500m² state-of-the-art facility and specialized research and development (R&D) team allow us to offer custom solutions that are perfect for the specific problems your drilling projects present. We can help you get better drilling results whether you're in coal mine, oil and gas extraction, or geological surveying. Don't let tough formations slow you down – contact us today at postmaster@hnsdrillbit.com to discover how our innovative PDC bits can revolutionize your drilling operations.

References

1. Smith, J. R., & Johnson, A. K. (2020). Advancements in PDC Bit Design for Hard Rock Drilling. Journal of Petroleum Technology, 72(5), 45-52.

2. Chen, W., Miska, S., & Cheng, Y. (2019). Performance Analysis of Three-Blade PDC Bits in Hard Rock Formations. SPE Drilling & Completion, 34(3), 210-225.

3. Thompson, L. M., & Davis, R. T. (2021). Comparative Study of Steel Body vs. Matrix PDC Bits in Challenging Drilling Environments. International Journal of Rock Mechanics and Mining Sciences, 138, 104648.

4. Wilson, E. J., & Brown, K. L. (2018). Thermal Management in PDC Bit Design: Impact on Bit Life and Drilling Efficiency. SPE/IADC Drilling Conference and Exhibition, Society of Petroleum Engineers.

5. Rodriguez, M. A., & Garcia, P. V. (2022). Optimization of Three-Blade PDC Bit Hydraulics for Improved Cuttings Evacuation in Hard Rock. Journal of Natural Gas Science and Engineering, 99, 104398.

6. Anderson, T. S., & Lee, H. R. (2023). Long-Term Performance Analysis of Steel Body PDC Bits in Abrasive Hard Rock Formations. Wear, 516-517, 204789.