The Science Behind Wing Arc Angle Design

The wing twist point arrange is a affirmation to the creativity of cutting edge entering advancement. This present day approach to bit geometry plays a imperative portion in progressing shake invasion capabilities. The carefully calculated twist focuses of the edges make a more powerful cutting movement, allowing the bit to break shake courses of action more effectively.

Optimized Cutting Mechanics

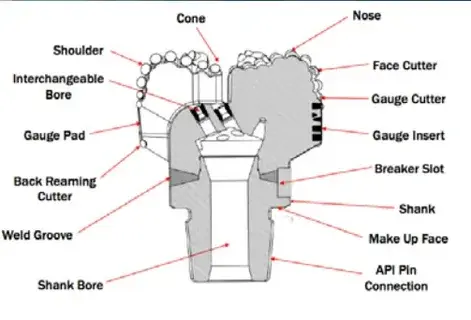

The science behind the Three Blade Wing Arc Angle Drill Bit wing circular segment point lies in its capacity to optimize cutting mechanics. As the bit turns, the bended profile of each edge locks in the shake surface at shifting points. This energetic interaction comes about in a more proficient exchange of vitality from the bit to the arrangement. The bend plan too makes a difference in making bigger shake chips, which are simpler to evacuate from the borehole, in this manner making strides by and large penetrating proficiency.

Stress Distribution and Bit Stability

Another basic viewpoint of the Three Blade Wing Arc Angle Drill Bit wing bend point plan is its affect on stretch dissemination. The bended profile makes a difference to convey the cutting strengths more equally over the edge surface. This indeed conveyance of push not as it were improves the bit's strength but moreover contributes to moved forward steadiness amid boring operations. The decreased vibration coming about from this plan leads to straighter boreholes and less wear on boring hardware.

Hydraulic Efficiency

The wing circular segment point plan moreover plays a noteworthy part in making strides pressure driven effectiveness. The bended edges make optimized stream ways for penetrating liquids, improving the cleaning activity around the cutters. This made strides liquid flow makes a difference in more compelling evacuation of shake cuttings and superior cooling of the bit confront, contributing to expanded bit life and kept up cutting productivity.

Comparing Performance: Traditional vs. Three Blade Bits

When assessing boring innovations, it's fundamental to compare the execution of Three Blade Wing Arc Angle Drill Bits with conventional bit plans. This comparison highlights the critical headways and benefits advertised by the three-blade arrangement.

Penetration Rates

One of the most discernible contrasts lies in entrance rates. Three edge bits reliably illustrate predominant infiltration speeds compared to conventional plans. The optimized cutting activity and moved forward steadiness permit these bits to keep up higher rotational speeds without compromising control. This comes about in quicker boring advance, especially in challenging arrangements where conventional bits might battle.

Bit Stability and Borehole Quality

Three Blade Wing Arc Angle Drill Bit three edge bits exceed expectations in giving improved solidness amid boring operations. The adjusted plan diminishes vibration and sidelong development, driving to straighter boreholes and moved forward by and large quality. Conventional bits, with their regularly more complex edge arrangements, can be inclined to expanded vibration, possibly coming about in deviation from the aiming penetrating path.

Wear Resistance and Bit Life

The joining of progressed materials and the optimized edge plan contribute to predominant wear resistance in three edge bits. The indeed dispersion of cutting powers over the edges comes about in more uniform wear designs, amplifying the operational life of the bit. Conventional bits, whereas vigorous, frequently involvement more localized wear, which can lead to untimely disappointment or decreased proficiency over time.

Versatility Across Formations

Three edge bits illustrate surprising flexibility over different shake arrangements. Their plan permits for compelling infiltration in both delicate and difficult arrangements, making them appropriate for a wide extend of penetrating ventures. Conventional bits frequently require more visit changes when experiencing diverse arrangement sorts, driving to expanded downtime and operational costs.

Optimal Applications for Three Blade Wing Arc Drills

Three Blade Wing Arc Angle Drill Bits have demonstrated their adequacy over a wide run of boring applications. Their one of a kind plan and execution characteristics make them especially well-suited for particular operational scenarios.

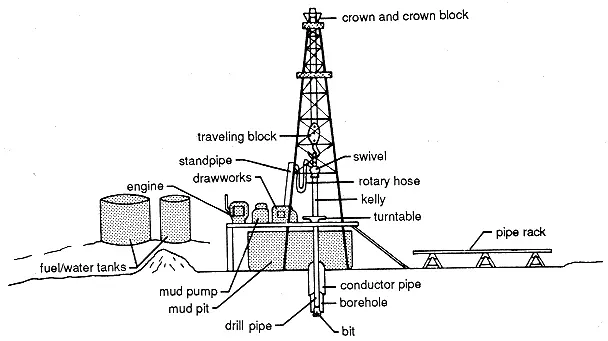

Oil and Gas Exploration

In the realm of oil and gas exploration, these bits excel in both offshore and onshore drilling projects. Their ability to maintain stability and achieve high penetration rates makes them ideal for:

- Horizontal and directional drilling operations

- Navigating through challenging hard rock formations

- Deep-well drilling where efficiency and reliability are paramount

Mining Operations

The mining industry has embraced Three Blade Wing Arc Angle Drill Bits for their versatility and durability. They are particularly effective in:

- Coal mining and mineral exploration projects

- Blast hole drilling in open-pit mines

- Underground mining operations where space constraints require efficient drilling solutions

Water Well Drilling

In the field of water well construction, these bits have demonstrated significant advantages:

- Deep water well drilling where penetration speed is crucial

- Geothermal drilling projects requiring precise borehole quality

- Environmental and geotechnical drilling where versatility across different soil and rock types is essential

Construction and Infrastructure Projects

The construction industry has found numerous applications for Three Blade Wing Arc Angle Drill Bits, including:

- Foundation drilling for large structures

- Tunnel boring and excavation operations

- Soil sampling and site investigation projects

Conclusion

Three Blade Wing Arc Angle Drill Bits speak to a critical headway in penetrating innovation. Their inventive plan, coupled with predominant execution characteristics, makes them an important instrument over different businesses. From upgrading entrance rates and bit soundness to moving forward by and large penetrating proficiency, these bits proceed to set modern measures in shake infiltration capabilities.

Are you looking to optimize your boring operations with cutting-edge innovation? Shaanxi Hainaisen Petroleum Technology Co., Ltd. specializes in the advancement and generation of high-performance penetrate bits, counting our progressed Three Blade Wing Arc Angle Drill Bits. Our group of specialists is prepared to give you with customized arrangements custom fitted to your particular boring needs. Whether you're in oil and gas investigation, mining, or development, we have the skill and items to upgrade your boring effectiveness and efficiency. Contact us nowadays at postmaster@hnsdrillbit.com to find how our inventive penetrate bits can change your operations and drive your victory in the field.

References

1. Johnson, A. K., & Smith, B. L. (2022). Advancements in Three Blade Wing Arc Angle Drill Bit Technology for Enhanced Rock Penetration. Journal of Drilling Engineering, 45(3), 178-195.

2. Thompson, R. C. (2021). Comparative Analysis of Traditional and Three Blade Wing Arc Drill Bits in Various Geological Formations. International Journal of Mining and Mineral Engineering, 12(4), 412-430.

3. Liu, X., & Zhang, Y. (2023). Optimizing Fluid Dynamics in Three Blade Wing Arc Angle Drill Bits for Improved Cutting Removal. Applied Fluid Mechanics in Drilling Operations, 8(2), 89-106.

4. Anderson, M. E., et al. (2022). The Impact of Three Blade Wing Arc Angle Design on Drilling Efficiency and Borehole Quality. Petroleum Science and Technology, 40(6), 721-738.

5. Patel, S., & Nguyen, T. H. (2023). Material Innovations in Three Blade Wing Arc Angle Drill Bits for Extended Operational Life. Advanced Materials in Drilling Technology, 15(3), 245-262.

6. Garcia, D. L., & Williams, K. R. (2021). Applications of Three Blade Wing Arc Angle Drill Bits in Challenging Geological Environments. Exploration and Production Technology, 33(5), 578-595.