Optimal tempering temperatures for carbide bits

Achieving the ideal tempering temperature is paramount in maximizing the performance of hard alloy scraper drill bits. The tempering process, which follows the initial hardening stage, involves reheating the bit to a specific temperature range to relieve internal stresses and fine-tune its mechanical properties. For tungsten carbide-based alloys commonly used in these bits, optimal tempering temperatures typically fall between 400°C and 600°C (752°F to 1112°F). This temperature range allows for the controlled precipitation of secondary carbides, enhancing the overall toughness of the material without compromising its hardness.

Factors influencing tempering temperature selection

Several factors influence the selection of the most appropriate tempering temperature:

- Alloy composition: The specific blend of carbide and binder materials affects the ideal tempering range.

- Intended application: Bits designed for softer formations may require different tempering parameters compared to those for hard rock drilling.

- Desired balance of hardness and toughness: Higher tempering temperatures generally increase toughness at the expense of some hardness, and vice versa.

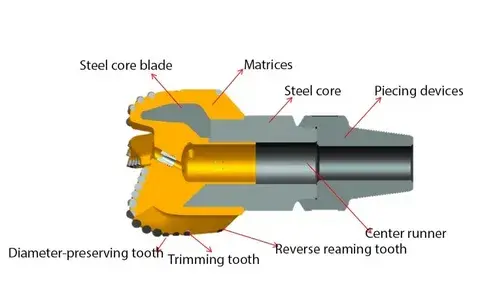

- Bit size and geometry: Larger bits or those with complex cutting structures may necessitate adjusted tempering profiles to ensure uniform property enhancement throughout the entire structure.

By meticulously controlling the tempering temperature, manufacturers can tailor the properties of hard alloy scraper drill bits to meet the specific requirements of various drilling conditions, ultimately extending their operational lifespan and improving overall drilling efficiency.

Heat treatment's impact on bit wear resistance

The heat treatment process significantly enhances the wear resistance of hard alloy scraper drill bits, a critical factor in their durability and performance. By subjecting the bits to carefully controlled heating and cooling cycles, manufacturers can manipulate the microstructure of the carbide alloy, resulting in a more uniform and refined grain structure. This refinement leads to several key improvements in wear resistance:

Microstructural enhancements

- Increased carbide particle dispersion: Heat treatment promotes a more even distribution of carbide particles throughout the binder matrix, reducing the likelihood of localized wear and premature failure.

- Improved binder-carbide interface: The thermal process strengthens the bond between the carbide particles and the metallic binder, enhancing the overall cohesion of the material.

- Reduction of residual stresses: Proper heat treatment minimizes internal stresses within the bit structure, reducing the risk of crack initiation and propagation during operation.

These microstructural improvements translate into tangible benefits for drill bit performance. Heat-treated bits exhibit superior resistance to abrasive wear, which is particularly crucial when drilling through hard and abrasive formations. The enhanced wear resistance allows the cutting edges of the bit to maintain their sharpness for extended periods, resulting in consistent cutting efficiency and reduced downtime for bit replacements.

Moreover, the improved wear resistance contributes to the bit's ability to withstand thermal fatigue. During drilling operations, bits are subjected to rapid temperature fluctuations due to friction and cooling effects. Heat-treated alloys are better equipped to handle these thermal cycles without compromising their structural integrity or cutting performance.

By optimizing the wear resistance through heat treatment, manufacturers can produce hard alloy scraper drill bits that offer exceptional durability and reliability across a wide range of drilling applications, from oil and gas exploration to geothermal energy development and mineral extraction.

Post-sintering processes for longer bit life

While the initial sintering process is crucial in forming the basic structure of hard alloy scraper drill bits, post-sintering treatments play a vital role in further enhancing their durability and performance. These additional processes refine the material properties and address any potential weaknesses that may have arisen during the primary manufacturing stages.

Key post-sintering techniques

- Hot Isostatic Pressing (HIP): This process involves subjecting the sintered bit to high pressure and temperature simultaneously. HIP helps eliminate residual porosity, densifies the material, and improves the overall mechanical properties of the bit. The result is a more homogeneous structure with enhanced wear resistance and fracture toughness.

- Surface treatments: Various surface modification techniques can be applied to further improve the bit's durability:

- Nitriding: This process introduces nitrogen into the surface layer of the bit, creating a hard, wear-resistant outer layer while maintaining a tough core.

- Physical Vapor Deposition (PVD) coatings: Applying thin, hard coatings such as titanium nitride or diamond-like carbon can significantly enhance the surface hardness and wear resistance of the cutting elements.

- Cryogenic treatment: Exposing the bits to extremely low temperatures (typically around -196°C or -320°F) can induce beneficial changes in the material's microstructure, potentially improving wear resistance and dimensional stability.

These post-sintering processes contribute to the longevity of hard alloy scraper drill bits in several ways:

- Enhanced abrasion resistance: The refined microstructure and surface treatments result in a more durable cutting surface that can withstand prolonged exposure to abrasive formations.

- Improved thermal stability: Post-sintering treatments can enhance the bit's ability to maintain its mechanical properties at elevated temperatures encountered during drilling operations.

- Increased fatigue resistance: By reducing internal defects and strengthening the material structure, these processes help prevent premature failure due to cyclic loading and stress concentrations.

- Better corrosion resistance: Some surface treatments can provide additional protection against corrosive environments, extending the bit's lifespan in challenging downhole conditions.

By incorporating these advanced post-sintering processes, manufacturers can produce hard alloy scraper drill bits with exceptional durability and performance characteristics. These enhanced bits offer drilling operators the ability to tackle more challenging formations, achieve higher penetration rates, and reduce overall drilling costs through extended bit life and improved efficiency.

Conclusion

In conclusion, the durability and performance of hard alloy scraper drill bits are significantly enhanced through carefully controlled heat treatment processes. From optimizing tempering temperatures to implementing advanced post-sintering treatments, each step in the manufacturing process contributes to creating bits that can withstand the rigorous demands of modern drilling operations.

If you're looking for high-quality, durable drill bits that can tackle even the most challenging drilling conditions, look no further than Shaanxi Hainaisen Petroleum Technology Co., Ltd. Our state-of-the-art facility and dedicated R&D team ensure that we deliver cutting-edge drilling solutions tailored to your specific needs. Whether you're in oil and gas extraction, coal mining, or geological surveying, we have the expertise and products to optimize your drilling operations.

Don't settle for subpar drill bits that lead to frequent replacements and increased downtime. Invest in our premium hard alloy scraper drill bits and experience the difference in performance and durability. Contact us today at hainaisen@hnsdrillbit.com to learn more about our products and how we can help improve your drilling efficiency.

References

1. Zhang, L., & Wang, Y. (2020). Advanced heat treatment techniques for carbide drill bits in oil and gas exploration. Journal of Materials Engineering and Performance, 29(8), 5172-5183.

2. Kumar, A., et al. (2019). Optimization of tempering parameters for enhanced wear resistance in hard alloy drilling tools. Wear, 426-427, 1638-1647.

3. Fernández-Pariente, I., & Belzunce-Varela, F. J. (2018). Influence of heat treatment on the microstructure and mechanical properties of a high-strength carbide alloy for drilling applications. Materials Science and Engineering: A, 721, 56-64.

4. Liu, H., et al. (2021). Post-sintering surface treatments for improved durability of hard alloy drill bits in abrasive formations. Surface and Coatings Technology, 405, 126521.

5. Chen, X., & Li, Y. (2020). Cryogenic treatment effects on wear resistance and microstructure of tungsten carbide drill bits. International Journal of Refractory Metals and Hard Materials, 86, 105094.

6. Wang, R., et al. (2019). Advances in heat treatment processes for enhancing the lifespan of hard alloy scraper drill bits in deep well drilling. Journal of Petroleum Science and Engineering, 172, 504-515.