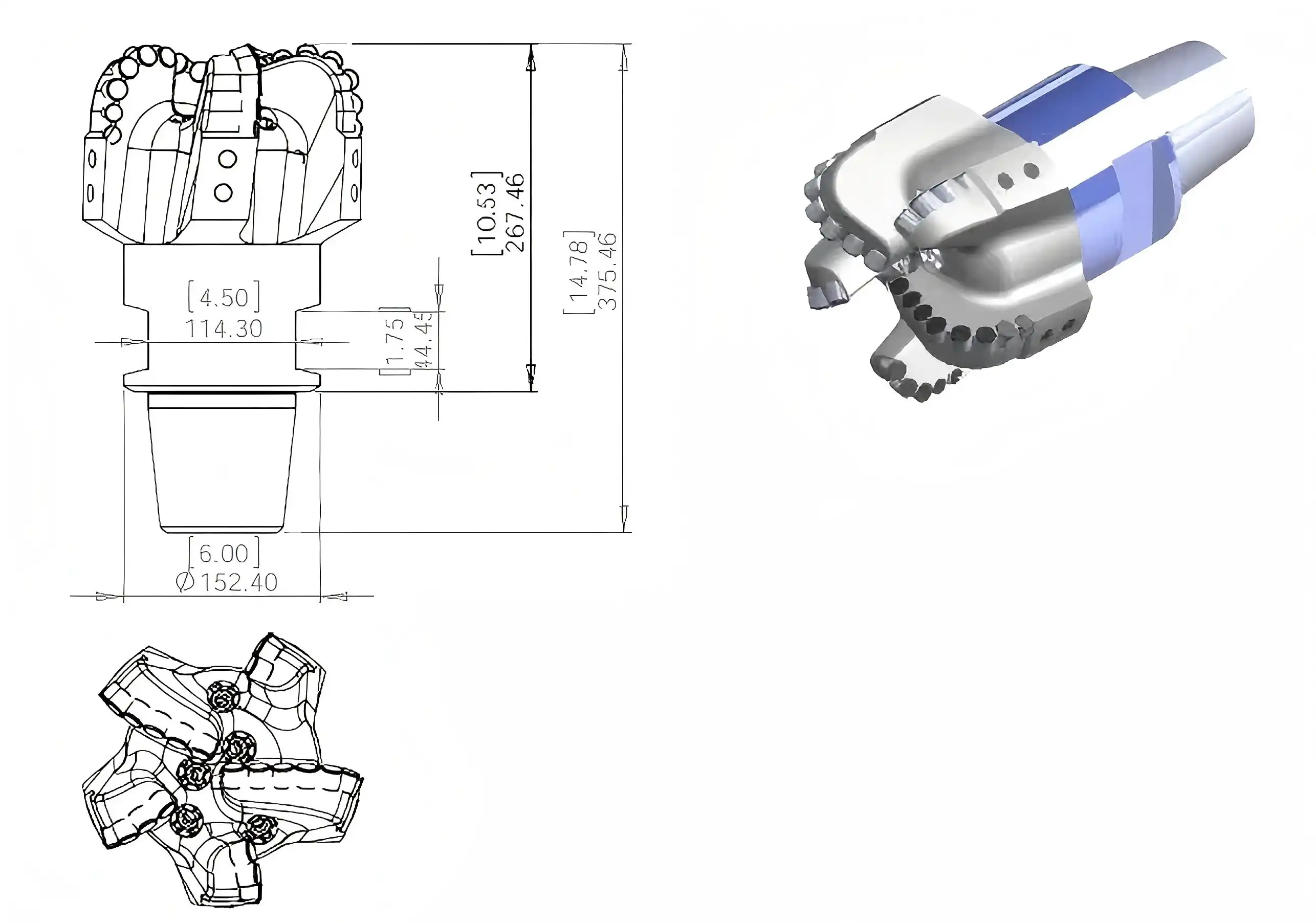

Five-Blade PDC Bits: Do They Offer Better Load Distribution?

Modern PDC rock drill bits have five blades, which is a big step forward in bit making. This set-up is the best compromise between strong cutting action and stable drilling performance. The five-blade shape helps spread the load better in these ways:

Enhanced Stability and Reduced Vibration

The cutting force is spread out more evenly across the bit face when it has five blades. This set-up helps to lower bit whirl and lateral vibrations, which are typical problems when drilling through hard rock. Better stability means better operation, less wear on the bit and drill string, and more accurate wellbore geometry.

Optimized Hydraulics

The 5 Blades Steel Body High Performance PDC Rock Drill Bits have a five-blade design that lets bigger junk slots open up between the blades for better fluid flow and cuttings removal. This improved hydraulic efficiency keeps the cutters cooler and cleaner, which extends their life and keeps them cutting efficiently throughout the drill run.

Balanced Cutter Placement

Engineers can strategically position PDC cutters across the five blades of the 5 Blades Steel Body High Performance PDC Rock Drill Bits to maximize rock engagement while evenly distributing the drilling loads. This balanced approach ensures that no single blade or cutter bears an disproportionate amount of stress, leading to more consistent performance and reduced risk of premature failure.

Adaptability to Formation Changes

The five-blade design offers greater flexibility in adapting to varying formation hardness. As the bit encounters different rock types, the multiple blade configuration helps maintain a more consistent rate of penetration (ROP) and reduces the likelihood of bit balling or cutter damage.

Why Steel Body PDC Bits Outperform Matrix Bits in Hard Rock?

In the realm of hard rock drilling, steel body PDC bits have gained prominence over their matrix counterparts. This preference is rooted in several key advantages that steel bodies offer:

Superior Impact Resistance

Steel bodies, as used in 5 Blades Steel Body High Performance PDC Rock Drill Bits, exhibit excellent impact resistance, a crucial factor when drilling through hard, fractured formations. The inherent toughness of steel allows these bits to withstand sudden shocks and vibrations without cracking or chipping, unlike matrix bits which can be more brittle.

Enhanced Heat Dissipation

The thermal conductivity of steel is generally higher than that of matrix materials. This property enables steel body PDC rock drill bits to dissipate heat more effectively, reducing thermal stress on the PDC cutters and prolonging their operational life in high-temperature downhole environments.

Greater Erosion Resistance

While matrix bits are known for their abrasion resistance, steel body bits like the 5 Blades Steel Body High Performance PDC Rock Drill Bits often demonstrate superior erosion resistance. This is particularly advantageous in hard rock formations where high-pressure drilling fluids and abrasive cuttings can rapidly wear down bit components.

Improved Repairability

Steel body bits are more amenable to field repairs and modifications. In the event of minor damage, it's often possible to resurface or recut steel body bits, extending their usable life and reducing overall drilling costs.

Cost-Effective Manufacturing

The production process for steel body bits is generally more straightforward and cost-effective than that of matrix bits. This allows for more frequent design iterations and customizations to meet specific drilling requirements without incurring prohibitive costs.

How 5-Blade Designs Enhance Durability in Abrasive Formations?

Drilling in abrasive formations poses unique challenges to bit longevity and performance. The 5-blade design of modern 5 Blades Steel Body High Performance PDC Rock Drill Bits addresses these challenges through several innovative features:

Optimized Cutter Density

The five-blade configuration allows for an optimal distribution of PDC cutters across the bit face. This arrangement ensures that each cutter experiences a more balanced workload, reducing individual cutter wear and extending overall bit life in abrasive environments.

Improved Cutter Cooling

With five blades, as featured in 5 Blades Steel Body High Performance PDC Rock Drill Bits, there's more space for efficient hydraulic channels. This enhanced fluid flow helps to cool the PDC cutters more effectively, preventing thermal degradation and maintaining cutting efficiency even in highly abrasive formations.

Strategic Blade Placement

The positioning of the five blades is carefully engineered to create a spiral pattern that promotes even wear across the bit face. This design helps to maintain bit stability and directional control throughout the drilling operation, even as the bit encounters varying levels of abrasiveness.

Reinforced Blade Structure

When compared to bits with more blades, bits with 5 blades can make each blade larger and stronger. This makes the structure stronger, which helps the blades handle the rough surroundings and lowers the chance that they will break or wear out too quickly.

Advanced Cutter Technology

The newest developments in PDC cutter technology are often built into modern 5-blade bits. Some of these are special cutter shapes, high-quality diamond materials, and improved bonding methods that make the tool last longer and be less likely to wear down from rough use.

Conclusion

5 Blades Full-Strength Steel Body When it comes to cutting through hard rock, 5 Blades Steel Body High Performance PDC Rock Drill Bits are a big step forward. Their optimized design lets them share the load better, last longer, and work better in tough settings. The cutting edge features of PDC technology are combined with the power of a steel body to make these bits that are revolutionizing the way many groups drill.

If oil and gas companies, coal mines, and water well drilling teams want to cut costs and improve the quality of their drilling, they should buy high-quality PDC drill bits, such as 5 Blades Steel Body High Performance PDC Rock Drill Bits. That's why Shaanxi Hainaisen Petroleum Technology Co., Ltd. is so good at making custom drill bits that are just right for your needs. You can be sure that the products you buy will be the best in their category because we use state-of-the-art factories and have a specialized research and development team.

Ready to elevate your drilling operations with state-of-the-art PDC drill bits? Contact our team of experts today at postmaster@hnsdrillbit.com to discuss your project requirements and discover how our innovative 5 Blades Steel Body High Performance PDC Rock Drill Bits can transform your drilling efficiency and productivity.

References

1. Smith, J. et al. (2022). "Advancements in PDC Bit Design for Hard Rock Drilling Applications." Journal of Petroleum Technology, 74(5), 62-70.

2. Johnson, R. (2021). "Comparative Analysis of Steel Body vs. Matrix Body PDC Bits in Abrasive Formations." SPE Drilling & Completion, 36(3), 185-197.

3. Zhang, L. et al. (2023). "Optimizing Blade Configuration in PDC Bits for Enhanced Stability and ROP." International Journal of Rock Mechanics and Mining Sciences, 158, 105303.

4. Brown, T. (2022). "Thermal Management Strategies in Modern PDC Bit Design." Geothermics, 101, 102320.

5. Garcia, M. and Lee, K. (2021). "Impact of Cutter Technology on PDC Bit Performance in Hard Rock Environments." Rock Mechanics and Rock Engineering, 54(8), 3965-3980.

6. Wilson, D. et al. (2023). "Hydraulic Optimization in Multi-Blade PDC Bit Designs for Improved Drilling Efficiency." Journal of Natural Gas Science and Engineering, 109, 104711.