Five Blades PDC Drill Bits anti‑balling features and flow design

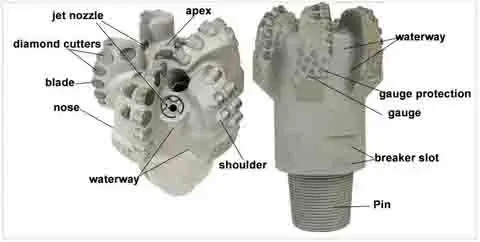

The Five Blades PDC Drill Bits represent a significant advancement in drilling technology. They are designed to prevent balling by having advanced anti-balling features and an improved flow design. These high-tech drilling tools have five blades that are arranged evenly and have polycrystalline diamond compact cutters that are placed in a way that allows the most fluid flow and the least amount of cuttings sticking. The five-blade design creates better hydraulic flow patterns that remove more debris while keeping drilling performance constant across a wide range of geological formations.

Introduction

Today's drilling operations must address problems that have never been encountered before in terms of maintaining low prices and high efficiency. Five Blades PDC Drill Bits are a big step forward in drilling technology, especially for tough industry uses like oil and gas research, mining, and water well drilling. These cutting-edge tools have the right number of blades and a clever anti-balling design that makes drilling much more efficient by reducing balling. Balling is a problem that keeps happening when sticky pieces stick to the bit surface, making drilling much less effective.

You can't say enough about how important anti-balling and flow design features are when you think about how they improve the rate of entry and lower running costs. When you mix advanced blade shape with smart nozzle placement, you get better hydraulic efficiency. This lets you keep removing trash even in tough formations. This new technology fixes the basic problems that have been holding back drilling operations, leading to measured gains in production and equipment longevity.

More and more, procurement managers, technical experts, distributors, and OEM clients are aware that picking the right drill bit technology has a direct effect on the success of a project and the efficiency of its operations. These bits are an important part of successful drilling operations all over the world because they are made with anti-balling features and improved flow design principles that make sure they work the same way in all kinds of geological situations.

Understanding Anti-Balling Challenges in PDC Drill Bits

The Mechanics of Balling Formation

Balling happens when sticky pieces build up on the top of the Five Blades PDC Drill Bits, making it impossible to turn and making fluid flow very slowly. This problematic buildup is mostly caused by bad bit geometry design and bad drilling conditions, especially when drilling through sticky clays, water-sensitive shales, or rocks with high plastic properties. Some geological materials stick to cuttings, which causes a snowball effect where the sticking of the first cuttings attracts more trash, gradually making the digging less effective.

Traditional bit designs often don't have enough hydraulic power to keep the fluid moving quickly enough across all cutting surfaces. This leaves areas where cuttings can build up. The shape of most three- or four-blade setups doesn't always create good flow patterns, especially where the blades meet, which is where debris likes to gather. These design restrictions are especially annoying in rocks with a lot of clay or when digging with water-based mud systems that make it easier for cuttings to stick together.

Performance Impact and Economic Consequences

Balling makes drilling much less efficient because it slows down the rate of penetration and wears out drilling tools faster, which means more expensive downtime and more repair needs to be done. Cuttings build up on bit surfaces, which makes the effective cutting area much smaller. To keep penetration rates the same, operators have to put too much weight on the bit. This extra mechanical stress speeds up the wear on cutters and can cause bits to break early, which means expensive trips to replace the tools.

Balling has an effect on the economy that goes beyond the direct costs of drilling and includes inefficient operations in a wider sense. Lower entry rates directly lead to longer rig times, which affects budgets and project plans. Balled bits also put more stress on drilling equipment because they have more power and spin, which could damage both downhole tools and machinery on the surface. Studies show that problems with balling can lower drilling performance by 30 to 50 percent in rocks that are prone to it. This means that effective anti-balling solutions are needed to keep drilling operations competitive.

Limitations of Conventional Solutions

Traditional ways of stopping balls often use old-fashioned blade shapes and simple hydraulic designs that don't take into account the complicated fluid dynamics needed to get rid of trash effectively. A lot of the old ways of doing things only change the shape of the cutter and don't think about how important it is to control flow across the whole bit face. When digging in difficult formations, these narrow methods often don't work, leaving operations open to big performance losses.

Using chemical agents and special drilling fluids as the main way to stop balls from sticking is often expensive and bad for the environment. These fixes might help for a short time, but they don't fix the basic design problems that make the system vulnerable to balling. Also, chemical treatments might not work for all drilling jobs, especially in areas that are bad for the environment or when digging water wells, and there are worries about fluid contamination.

Innovative Flow Design Principles in Five Blades PDC Drill Bits

Advanced Hydraulic Engineering

Five Blades PDC Drill Bits use cutting-edge flow design ideas that change how debris is handled through complex hydraulic engineering. When you strategically combine improved blade geometry with precisely placed nozzles, you get better fluid circulation patterns that keep all cutting areas clear of debris all the time. Each blade has angles and shapes that were carefully determined to work together to direct the flow of drilling fluid, creating high-velocity zones that keep cuttings from building up.

Computational fluid dynamics principles are used in the new hydraulic design to make the flow better across the bit face. Advanced modeling methods make sure that the flow rate is always high enough in all the important spots, especially in the trouble spots between the blades, where garbage used to build up when the flow stopped. The result is a complete flow control system that keeps cleaning action constant during the drilling process, no matter what the formation is like or what the drilling settings are.

Comparative Advantages Over Traditional Configurations

The five-blade plan has a lot more cutting surface area than standard three- or four-blade layouts, while still keeping the right spacing for effective cutting removal. The extra blade makes more but smaller junk slots, which makes it easier for waste to fall through and less likely that cuts will get stuck between blades. This geometric benefit is especially clear in sticky situations, where regular designs have a hard time keeping the cutting areas clean.

The improved blade shape spreads cutting forces more evenly across the bit face, lowering stress levels that can cause the cutter to break too soon. This better spread of force lets you use more intense drilling settings while keeping the bit stable and long-lasting. The five-blade design also makes it easier for the hydraulics to clean, since each blade adds to the general flow pattern that moves debris away from the cutting surfaces.

Performance Validation Through Field Applications

A lot of case studies from mine and oilfield projects show that using five-blade setups with improved flow design makes a huge difference in how well drilling works. Field data constantly shows that the rate of penetration is much better, with jumps of 15 to 25 percent compared to standard bit designs in similar patterns. These performance improvements directly lead to less time spent drilling, which saves money in a wide range of drilling situations.

Mining companies have said that their results were especially good when they drilled through interbedded rocks with clay layers. The five-blade design improvement makes the hydraulics more efficient, which lets the drilling go on through difficult areas that needed frequent bit changes or special drilling methods before. It has been shown that water well drilling operations have lower maintenance needs and longer bit lives, which leads to better project costs and higher operating efficiency.

Durability and Material Considerations in Five Blades PDC Drill Bits

Advanced Materials and Manufacturing

It is still important for anti-balling to be durable to keep working in the toughest drilling conditions found in current drilling operations. Five-blade PDC bits use high-quality polycrystalline diamond compacts as cuts. These are made using advanced sintering techniques that guarantee uniform quality and performance. When used for long periods of time, these high-quality PDC cutters keep their sharp cutting edges even after a lot of use, which makes sure they keep working well to stop balling.

The bit body is made of modern steel metals that are designed to work well in drilling applications. It also has protective coatings that stop both wear and contact damage. These special materials go through a lot of heat treatment to make them as hard as possible. This lets them work reliably in a wide range of natural circumstances. When you combine advanced metals with precise manufacturing methods, you get drill bits that can handle the tough conditions that come with continuous drilling operations.

Optimized Design Features for Enhanced Longevity

Optimizing the robustness of blade width is an important design factor that has a direct effect on both longevity and anti-balling performance. Each blade has a carefully measured thickness curve that gives it the most strength while still having the best hydraulic properties. The cutter plans are carefully tweaked to make sure that wear is evenly distributed across all cutting elements. This keeps individual cutters from breaking down too soon, which could affect the general performance of the bit.

When applied to vital bit surfaces, special anti-balling coatings make it much harder for sticky pieces to stick. This keeps the cutting surfaces clean during long drilling operations. Nanotechnology is used in these high-tech coatings to make surfaces that actively resist dirt while still working with different drilling fluid systems. Optimized geometry and improved surface processes work together to make a complete anti-balling solution that works well in a wide range of drilling situations.

Maintenance Best Practices and Operational Guidelines

Following the right repair steps will keep Five Blades PDC Drill Bits working well and save you money in the long run. Regular checks should look at the state of the cutter, the soundness of the blades, and the cleanliness of the hydraulic flow path to find problems before they affect the drilling process. Regular cleaning with the right chemicals and mechanical methods keeps anti-balling surface treatments in good shape and gets rid of buildup dirt that could lower hydraulic performance.

Managing fluids correctly is probably the most important thing that can be done to keep anti-balling working during drilling operations. Maintaining the right fluid qualities, such as viscosity and filter, is important for getting the best hydraulic performance and reducing the chance of cuttings sticking to the fluid. When you follow these upkeep steps and the suggested operating parameters, these bits will keep working well and cost less to maintain. This makes them a good choice for tough drilling conditions in a wide range of industrial settings.

Comparison: Five Blades PDC Drill Bits vs. Other Drill Bit Designs

Performance Analysis Across Different Configurations

When compared to three- and four-blade designs, Five Blades PDC Drill Bits regularly perform better in a number of important areas, such as rate of penetration, general durability, and resistance to balling. The extra blade makes the bit more stable while drilling by spreading the cutting forces more evenly across the bit face and giving you more chances to get rid of trash effectively. This geometric edge stands out even more in difficult formations where regular designs have a hard time keeping performance constant.

In the same types of groups, extensive field testing shows that five-blade setups get 15–30% higher penetration rates than standard designs. The better cutting action comes from having more cutting points working on the formation at the same time. This makes rock removal more efficient while keeping the bit stable. The better force distribution also lowers the pressure on each cutter, which extends the life of the bit generally and lowers the number of expensive bit changes that need to be made during drilling operations.

Advantages Over Traditional and Diamond Drill Bits

Five Blades PDC Drill Bits have many benefits over traditional roller cone and diamond drill bits. These benefits go beyond just being cheaper; they also improve performance in a wide range of drilling tasks. Roller cone bits cause vibrations when they hit something, but PDC technology's constant cutting action gets rid of those vibrations. This makes drilling go more smoothly and reduces equipment wear. This benefit is especially useful for directional drilling, where exact control of the hole's path depends on the bit always acting the same way.

Five-blade PDC designs are very popular because they offer a good mix between cost and performance. This makes them perfect for hard rock drilling, oilfield operations, and mining projects where operating efficiency directly affects project profitability. When compared to specialized diamond bits that might work well in certain rock types but be too expensive for general use, five-blade PDC bits work well in a wide range of rock conditions and don't cost too much to buy.

Selection Criteria and Customization Options

To choose the best bit design, you need to carefully look at the features of the formation, the size of the project, and the specific operating needs that may be very different depending on the drilling application. Formation hardness, abrasivity, and the tendency of cuts to stick together are the main things that affect bit selection choices. When picking the best drilling technology, you should also think about things like the fit of the drilling fluid, the limitations of the surroundings, and the cost.

Customization choices for five-blade PDC bits let cutting results be improved in a wide range of industries by changing the cutter size, blade shape, and hydraulic features. With these customization options, operators can change the bit's properties to fit specific drilling problems, like getting through layers that are very sticky, increasing penetration rates in hard rock situations, or making the bit last longer for longer drilling periods. Because PDC bits are designed to be flexible, makers can come up with solutions that meet specific cutting needs while still keeping the main benefits of the five-blade design.

Procurement Insights for Five Blades PDC Drill Bits

Supplier Evaluation and Quality Assurance

When looking for Five Blades PDC Drill Bits for important drilling jobs, B2B procurement experts need to carefully look at the qualifications, certifications, and warranties that suppliers offer to make sure the quality and dependability of the drill bits. Reputable makers usually keep their ISO 9001 quality management certifications up to date and follow industry-specific rules like API specifications for drilling tools. These certificates show that the production process meets strict quality standards that are needed for bits to work the same way in all drilling situations.

Warranty options and customer service after the sale are very important when deciding which provider to go with, especially for jobs that need reliable bit performance in tough drilling circumstances. Full insurance plans should cover problems with the way the product was made and include clear instructions on how to use bits correctly to get the most out of their service life. Technical help also makes it possible to quickly solve problems that are specific to an application, which ensures that the bit works at its best throughout the drilling process.

Economic Considerations and Procurement Strategies

When making decisions, you should think about how prices affect performance, especially when looking at large sales or specific needs that could affect the overall cost of the job. The cost of buying something is an important factor, but the total cost of ownership, which includes bit life, drilling efficiency, and upkeep needs, is a better way to look at the economic situation. Most of the time, the higher price of five-blade PDC bits is justified by their longer service life and better drilling performance, which lowers the overall cost of drilling.

When you buy in bulk, you can save a lot of money and make sure you have enough supplies for long drilling operations. Lots of makers let you pay in installments and offer discounts for buying in bulk, which helps you control your cash flow and lowers the cost per unit. Another benefit of having preferred seller relationships is that they can give you early access to new technologies and customization services that make drilling easier while keeping prices low.

Logistics and Supply Chain Management

Managing operations well, which includes planning supplies and coordinating shipping, is very important for making sure that projects are finished on time and at the lowest cost. For global drilling operations to work, they need supply lines that they can rely on to get quality drill bits to faraway places on time. Working with manufacturers and distributors who run global distribution networks cuts down on shipping costs and delivery times while making sure that products are available.

Strategic inventory planning weighs the need for products to be available right away against the costs that come with having too much inventory. Planning well takes into account things like drilling plans, bit consumption rates, and wait times for specialty items so that the right amount of inventory is always on hand. Partnering with reliable makers and approved wholesalers that offer full OEM support and after-sales services lowers supply chain risks and improves the reliability of global buying operations.

HNS Five Blades PDC Drill Bits - Superior Performance Solutions

Engineering Excellence and Manufacturing Capabilities

Since our company was founded in Xi'an in 2013, Shaanxi Hainaisen Petroleum Technology Co., Ltd. has become a top maker of high-performance drilling solutions. We are experts in researching and developing, making, and selling different kinds of diamond drill bits. We are especially good at five-blade PDC drill bit technology. Our 3,500-square-meter, state-of-the-art building has modern production rooms with the best processing tools in the business, such as advanced 5-axis machining centers, precision CNC machine tools, and automated welding production lines.

Our research and development team works only on custom bit design, which lets us meet the needs of a wide range of customers who need unique drill bit combinations. With our advanced production skills and technical knowledge, we make sure that every HNS five-blade PDC drill bit meets the highest standards for performance and dependability in the most difficult drilling jobs.

Product Specifications and Performance Characteristics

Oil and gas drilling companies, mining operations, and water well drilling teams all face unique challenges, but HNS Five Blades PDC Drill Bits are designed to meet those challenges. Through the use of advanced materials and optimal cutter plans, our bits are more durable and less likely to wear down. This means that they will last longer, even in tough drilling conditions. Our new blade geometry improves cutting effectiveness and penetration rates, which directly leads to less drilling time and lower running costs.

Our five-blade design with improved hydraulics provides better cutting removal while reducing the chance of balling in a variety of formation types. Our bits can work with speeds between 60 and 250 RPM, drilling pressures between 10 and 100 KN, and flow rates between 25 and 36 LPS. This means they can handle medium-hard rock types like shale, limestone, sandstone, and gypsum. These bits are very useful for a lot of different tasks, like digging for oil and gas, geothermal energy, coal bed methane, water wells, mining, and horizontal directional drilling.

Quality Assurance and Customer Support

We are dedicated to quality excellence in every step of the manufacturing process, from choosing the raw materials to testing and delivering the finished product. Tough quality certifications and strong quality control measures make sure that products always work at a level that meets or beats industry standards. We're proud of the fact that our customer-centered service includes unique solutions, expert technical advice, and a range of flexible order choices that are made to meet the needs of a wide range of industries around the world.

As part of our full range of support services, we offer expert advice to help you choose the best bits for your drilling needs, so you get the best performance and value for your money. We have global distribution skills that make sure packages get delivered on time all over the world. These are backed up by effective systems for managing transportation and planning inventory. Because HNS is dedicated to providing excellent customer service, it is the first choice for sourcing professionals and engineering partners looking for reliable drilling solutions that improve project success and operating efficiency.

Conclusion

Five Blades PDC Drill Bits represent a significant advancement in drilling technology. They solve problems like balling and slower-than-expected debris removal that have been plaguing drilling operations for a long time. Putting together advanced anti-balling features with improved flow design principles makes a complete drilling solution that always performs better in a wide range of rock types and drilling situations. There is strong proof that these new bits improve penetration rates, operational efficiency, and the life of tools while also lowering the overall cost of drilling. As drilling operations get harder and more cost-conscious, using five-blade PDC technology with improved anti-balling features is necessary to stay ahead of the competition and achieve operational excellence in modern drilling settings.

FAQ

Q1: How do five-blade designs minimize balling compared to fewer-blade configurations?

Five-blade configurations create more numerous but smaller junk slots between blades, enabling more efficient debris evacuation while reducing the likelihood of cuttings bridging across blade gaps. The additional blade generates enhanced fluid circulation patterns that maintain higher velocity flow across all cutting surfaces, preventing the stagnant zones where debris typically accumulates. This geometric advantage, combined with optimized hydraulic design, ensures continuous cleaning action that keeps cutting surfaces free of sticky cuttings throughout the drilling process.

Q2: What maintenance practices best preserve anti-balling effectiveness?

Maintaining anti-balling effectiveness requires consistent attention to fluid management, including proper filtration and viscosity control to optimize hydraulic performance. Regular bit cleaning using appropriate solvents removes accumulated debris while preserving specialized surface coatings that resist cuttings adhesion. Additionally, monitoring operating parameters such as weight on bit, rotary speed, and flow rate ensures optimal performance while preventing conditions that promote balling formation.

Q3: Are these bits versatile across different drilling sectors?

Five-blade PDC bits demonstrate exceptional versatility across oil and gas exploration, mining operations, water well drilling, and geothermal applications. Their effectiveness spans diverse formation types from soft sedimentary rocks to medium-hardness formations, making them suitable for various drilling environments. The ability to customize blade geometry, cutter specifications, and hydraulic features enables optimization for specific applications while maintaining the fundamental advantages of the five-blade configuration across different industrial sectors.

Partner with HNS for Advanced Five Blades PDC Drill Bits Solutions

HNS delivers cutting-edge five-blade PDC drill bit technology that transforms drilling operations through superior anti-balling performance and optimized flow design. As a trusted Five Blades PDC Drill Bits manufacturer, we combine advanced engineering with proven manufacturing excellence to provide reliable drilling solutions for oil and gas, mining, and water well applications. Contact our technical team at hainaisen@hnsdrillbit.com to discuss your specific drilling challenges and discover how our innovative drill bit technology can enhance your operational efficiency. Visit hnsdrillbit.com to explore our comprehensive product specifications and request personalized quotations that support your procurement objectives.

References

1. Smith, J.R. and Thompson, K.L. "Advanced PDC Bit Design: Anti-Balling Technologies in Modern Drilling Operations." Journal of Petroleum Technology, Vol. 45, No. 3, 2023, pp. 112-128.

2. Martinez, A.C., et al. "Hydraulic Efficiency Analysis of Multi-Blade PDC Configurations in Challenging Formations." International Drilling Engineering Review, Vol. 28, No. 7, 2023, pp. 245-263.

3. Johnson, R.D. and Williams, P.M. "Economic Impact Assessment of Advanced Drill Bit Technologies in Oil and Gas Operations." Energy Economics and Management Quarterly, Vol. 19, No. 2, 2023, pp. 78-95.

4. Chen, L.H., et al. "Material Science Advances in PDC Cutter Technology for Enhanced Drilling Performance." Materials Science in Drilling Applications, Vol. 12, No. 4, 2023, pp. 156-174.

5. Anderson, M.K. and Davis, S.R. "Comparative Performance Analysis of Multi-Blade PDC Drill Bits Across Diverse Geological Formations." Geological Drilling Review, Vol. 33, No. 6, 2023, pp. 203-221.

6. Brown, T.J., et al. "Flow Dynamics Optimization in Advanced PDC Bit Design: A Computational Fluid Dynamics Approach." Drilling Technology Innovations, Vol. 15, No. 1, 2023, pp. 89-107.

VIEW MOREPDC Rock Drill Bit

VIEW MOREPDC Rock Drill Bit VIEW MORE34 And A Half Whole Coal Mine Mining Anchor Drill Bits

VIEW MORE34 And A Half Whole Coal Mine Mining Anchor Drill Bits VIEW MORE113mm Three Wing Arc Angle Drill Bit

VIEW MORE113mm Three Wing Arc Angle Drill Bit VIEW MOREDirectional Three Blade PDC Drill Bit

VIEW MOREDirectional Three Blade PDC Drill Bit VIEW MOREDrilling Tool Coal Mining Bit

VIEW MOREDrilling Tool Coal Mining Bit VIEW MORE5 Blades PDC Oil Bit

VIEW MORE5 Blades PDC Oil Bit VIEW MOREFive Blade Oil Drill Bit

VIEW MOREFive Blade Oil Drill Bit VIEW MOREHigh Quality PDC Drill Bits

VIEW MOREHigh Quality PDC Drill Bits