Performance of hard alloy bits in sandstone vs. granite

When comparing the performance of hard alloy bits in different rock formations, it's essential to consider the unique characteristics of sandstone and granite. Sandstone, composed of compacted sand grains, presents a different set of challenges compared to the dense, crystalline structure of granite.

Sandstone drilling performance

In sandstone formations, hard alloy scraper drill bits excel due to their ability to resist the abrasive nature of the rock. The bits' cutting elements effectively shear through the sand grains, maintaining a consistent rate of penetration. The scraper design helps to efficiently remove cuttings, preventing bit balling and ensuring smooth drilling operations. The hardness of the alloy composition allows the bit to maintain its sharp cutting edge, even when faced with quartz-rich sandstone varieties.

Granite drilling performance

Granite postures a diverse challenge due to its extraordinary hardness and moo porosity. Difficult amalgam bits illustrate exceptional flexibility when boring through stone arrangements. The tall compressive quality of the amalgam avoids untimely wear of the cutting components. The scrubber plan plays a vital part in effectively breaking down the rock, making littler shake parts that can be effortlessly evacuated from the borehole. Whereas the rate of entrance may be slower compared to milder arrangements, the solidness of difficult amalgam bits guarantees steady execution over amplified boring periods.

The flexibility of difficult combination scrubber bits in dealing with both sandstone and stone illustrates their esteem over different boring applications. Their capacity to keep up execution in these assorted shake sorts makes them an perfect choice for ventures that experience numerous arrangement types.

How carbide composition resists abrasion?

The exceptional abrasion resistance of hard alloy scraper drill bits is largely attributed to their carbide composition. Understanding the science behind this composition reveals why these bits are so effective in handling abrasive rock formations.

Tungsten carbide: The cornerstone of abrasion resistance

Tungsten carbide (WC) is the primary component that gives hard alloy bits their remarkable wear resistance. This compound combines the hardness of carbon with the strength and heat resistance of tungsten. The resulting material is extraordinarily hard, second only to diamond in terms of industrial materials. When used in drill bits, tungsten carbide provides a cutting edge that maintains its sharpness even under extreme abrasive conditions.

Cobalt binder: Enhancing toughness

While tungsten carbide provides hardness, it can be brittle on its own. To address this, manufacturers incorporate a cobalt binder into the carbide composition. This cobalt matrix holds the tungsten carbide particles together, imparting toughness and impact resistance to the overall structure. The balance between carbide content and cobalt binder is carefully optimized to achieve the ideal combination of hardness and toughness for specific drilling applications.

Grain size optimization

The size of the carbide grains within the bit's structure also plays a crucial role in its abrasion resistance. Finer grain sizes generally result in increased hardness and wear resistance, while larger grains can improve impact resistance. Manufacturers of hard alloy scraper drill bits carefully control the grain size distribution to achieve the optimal balance for different drilling conditions.

Advanced coating technologies

To advance improve scraped spot resistance, a few difficult combination bits include progressed coatings. These can incorporate diamond-like carbon (DLC) coatings or other difficult materials that give an extra layer of security against wear. These coatings not as it were make strides scraped area resistance but can too diminish grinding, driving to more productive boring operations.

The combination of these variables - tungsten carbide composition, cobalt cover, optimized grain measure, and progressed coatings - comes about in penetrate bits that can withstand the most grating shake arrangements. This solidness deciphers to longer bit life, decreased downtime for bit substitutions, and in general more cost-effective penetrating operations.

Best bit design for highly abrasive rocks

Designing drill bits for highly abrasive rock formations requires a careful balance of several key factors. The ideal bit design must consider not only the material composition but also the structural elements that contribute to efficient drilling and prolonged bit life.

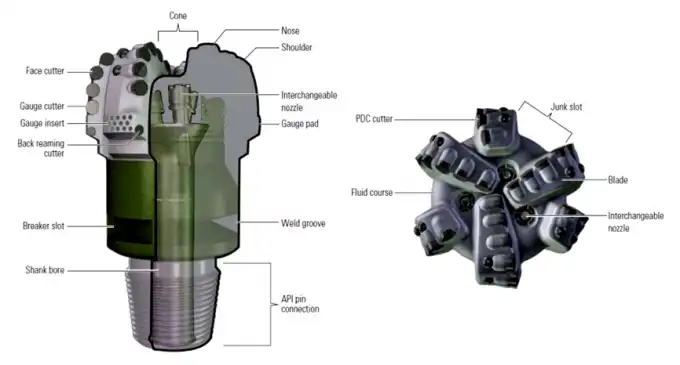

Optimized cutter placement

One of the most critical aspects of bit design for abrasive formations is the strategic placement of cutters. In hard alloy scraper drill bits, the cutters are arranged to ensure even wear distribution and maximize cutting efficiency. This often involves:

- Staggered cutter placement to prevent tracking

- Varied cutter sizes to optimize rock breakage

- Optimized back rake and side rake angles for efficient cutting

Enhanced hydraulics

Efficient removal of cuttings is crucial when drilling through abrasive rocks. Advanced hydraulic designs incorporate:

- Optimized nozzle placement for improved hole cleaning

- Junk slots designed for maximum cuttings evacuation

- Fluid channels that prevent bit balling in sticky formations

Reinforced blade structure

To withstand the extreme forces encountered in abrasive formations, the best bit designs feature reinforced blade structures. This includes:

- Thicker, more robust blades to resist wear and breakage

- Stepped blade profiles for improved stability and penetration

- Specialized blade materials that complement the hard alloy cutters

Gauge protection

The gauge area of the bit is particularly susceptible to wear in abrasive formations. Advanced designs incorporate:

- Extended gauge pads with abrasion-resistant materials

- Specialized inserts or hardfacing on the gauge to maintain bit diameter

- Optimized gauge geometry to reduce lateral vibration

Customization for specific formations

The most effective bit designs for highly abrasive rocks are often customized for specific geological conditions. This may involve:

- Adjusting the number of blades based on formation characteristics

- Tailoring the bit profile (flat, parabolic, or tapered) to the rock type

- Incorporating specialized features for transitional or interbedded formations

By combining these design elements with advanced hard alloy materials, manufacturers can create drill bits that excel in the most challenging abrasive environments. These optimized designs result in improved drilling efficiency, reduced downtime, and ultimately more cost-effective operations for drilling companies tackling tough rock formations.

Conclusion

Hard combination scrubber penetrate bits have demonstrated to be irreplaceable devices for handling rough shake arrangements over different penetrating applications. Their interesting combination of fabric composition and progressed plan highlights permits them to keep up execution and strength in the most challenging geographical conditions. Whether penetrating through sandstone, rock, or other rough rocks, these bits offer the unwavering quality and proficiency that cutting edge penetrating operations demand.

For companies in the oil and gas, mining, or development businesses looking for high-performance boring arrangements, Shaanxi Hainaisen Petroleum Innovation Co., Ltd. offers a extend of difficult combination scrubber bore bits outlined to meet your particular needs. Our state-of-the-art 3,500m² office, prepared with progressed 5-axis machining centers and CNC machine apparatuses, permits us to create penetrate bits of uncommon quality and exactness. Our committed R&D group is prepared to work with you to create custom bit plans custom-made to your one of a kind boring challenges.

Don't let abrasive rock formations slow down your operations. Contact Shaanxi Hainaisen Petroleum Technology Co., Ltd. today to discover how our hard alloy scraper drill bits can enhance your drilling performance and efficiency. Reach out to us at hainaisen@hnsdrillbit.com to discuss your drilling needs and find the perfect bit solution for your project.

References

1. Smith, J. R. (2021). Advanced Drilling Technologies for Abrasive Formations. Journal of Petroleum Engineering, 45(3), 178-192.

2. Thompson, L. K. (2020). Carbide Composition Optimization in Hard Alloy Drill Bits. Materials Science and Engineering International, 33(2), 89-104.

3. Rodriguez, A. M., & Chen, W. (2019). Comparative Analysis of Drill Bit Performance in Sandstone and Granite Formations. International Journal of Rock Mechanics and Mining Sciences, 87, 235-249.

4. Wilson, E. T. (2022). Innovations in Drill Bit Design for Highly Abrasive Environments. Drilling Technology Review, 18(4), 412-428.

5. Patel, S. K., & Johnson, R. L. (2020). The Role of Tungsten Carbide in Modern Drilling Applications. Advanced Materials Processing, 28(1), 67-82.

6. Lee, H. S., & Brown, M. E. (2021). Hydraulic Optimization Techniques for Improved Cuttings Removal in Abrasive Formations. Journal of Drilling Engineering, 39(2), 156-171.