What Structural Differences Define Flat Top vs Conical Sintered PCD Cutters?

The essential auxiliary contrast between Level Beat and Funnel shaped Sintered PCD (Polycrystalline Jewel Compact) cutters lies in their geometry and cutting edge plan. This variety in structure altogether impacts their execution characteristics and reasonableness for diverse penetrating applications.

Flat Top Sintered PCD Cutters

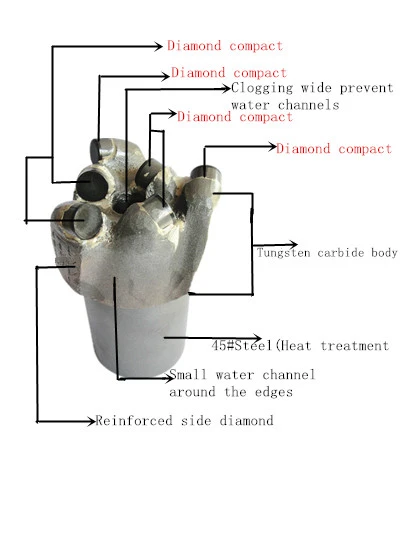

PDC Flat Top Sintered Drill Bits feature a planar cutting surface that extends across the entire face of the cutter. This design offers several advantages:

- Larger cutting surface area, allowing for more aggressive material removal

- Enhanced stability during drilling operations

- Improved heat dissipation due to the increased surface area

- Greater resistance to abrasive wear in softer to medium-hard formations

The level beat plan too permits for simpler fabricating and quality control forms, guaranteeing steady execution over clumps. Furthermore, the level surface encourages way better dispersion of boring powers, lessening the hazard of cutter harm beneath tall loads.

Conical Sintered PCD Cutters

Conical Sintered PCD cutters, as the name suggests, feature a cone-shaped cutting element. This unique geometry provides distinct benefits:

- Enhanced impact resistance, particularly beneficial in harder formations

- Improved penetration rates in certain rock types

- Reduced friction and heat generation at the cutter-rock interface

- Better self-sharpening characteristics as the cutter wears

The conical shape also allows for a more gradual engagement with the formation, which can lead to smoother drilling operations and reduced vibration in some circumstances.

Performance Trade-Offs: Aggressiveness vs Durability

When comparing PDC Level Best Sintered Bore Bits to Cone shaped Sintered Bits, it's fundamental to consider the trade-offs between forcefulness and solidness. These components essentially affect boring productivity, bit life, and in general cost-effectiveness.

Aggressiveness in Cutting Action

PDC Flat Top Sintered Drill Bit generally exhibit more aggressive cutting action due to their larger cutting surface area. This aggressiveness translates to:

- Higher rates of penetration (ROP) in softer to medium-hard formations

- More efficient removal of large volumes of material

- Improved drilling efficiency in homogeneous formations

However, this aggressiveness can be a double-edged sword. In harder or more abrasive formations, the flat top design may lead to accelerated wear or damage if not properly managed.

Conical Sintered Bits, while generally less aggressive, offer:

- More controlled cutting action, particularly beneficial in heterogeneous formations

- Reduced risk of bit balling in sticky formations

- Better performance in fractured or interbedded rock types

Durability Considerations

Durability is a critical factor in bit selection, as it directly impacts operational costs and downtime. In this aspect:

Flat Top Sintered Bits offer:

- Excellent wear resistance in abrasive environments

- Longer bit life in softer to medium-hard formations

- Better stability, reducing the risk of premature failure

Conical Sintered Bits excel in:

- Impact resistance, making them suitable for hard and fractured formations

- Maintaining cutting efficiency over longer runs in varied lithologies

- Resisting chipping and breakage in challenging drilling conditions

The choice between aggressiveness and durability often depends on specific formation characteristics, drilling parameters, and operational goals. Balancing these factors is crucial for optimizing drilling performance and cost-effectiveness.

Formation Matching: Where Flat vs Conical Types Excel Most?

Selecting the appropriate bit type based on formation characteristics is crucial for maximizing drilling efficiency and minimizing costs. Both Flat Top and Conical Sintered Bits have their sweet spots in terms of formation suitability.

Ideal Formations for Flat Top Sintered Bits

PDC Flat Top Sintered Drill Bits typically excel in:

- Soft to medium-hard formations

- Homogeneous rock types

- Sandstone and shale formations

- Formations with consistent compressive strength

These bits are particularly effective in environments where rapid penetration rates are desired and where the formation is not prone to causing excessive impact loading on the cutters.

Optimal Conditions for Conical Sintered Bits

Conical Sintered Bits are often the preferred choice in:

- Hard and abrasive formations

- Interbedded or heterogeneous rock types

- Fractured or naturally fissured formations

- Environments with high shock and vibration risks

The conical geometry provides better resistance to impact and chipping in these challenging conditions, often resulting in more consistent performance and longer bit life.

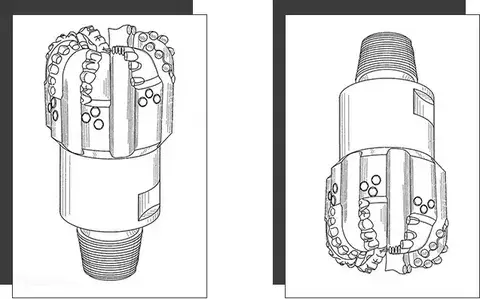

Hybrid Approaches

In some cases, a hybrid approach combining both flat top and conical cutters on a single bit can provide the best of both worlds. This strategy allows for:

- Optimized performance across a wider range of formation types

- Balanced aggressiveness and durability

- Improved versatility in transitional zones

Such hybrid designs can be particularly beneficial in wells with varied lithology or in exploratory drilling where formation characteristics may be less certain.

Customization for Specific Formations

Advanced manufacturing techniques now allow for customization of bit designs to match specific formation characteristics. This includes:

- Tailored cutter placement and orientation

- Optimized hydraulics for efficient cuttings removal

- Specialized matrix materials for enhanced durability

By leveraging these customization options, drilling engineers can fine-tune bit performance to match the unique challenges of their specific drilling environment, whether using flat top, conical, or hybrid designs.

Conclusion

The choice between PDC Flat Top Sintered Drill Bit and Funnel shaped Sintered Bits depends on a complex transaction of variables counting arrangement characteristics, boring parameters, and operational objectives. Level beat bits for the most part offer more forceful cutting activity and exceed expectations in gentler to medium-hard, homogeneous arrangements. Cone shaped bits, on the other hand, give improved solidness and affect resistance, making them perfect for harder, more heterogeneous environments.

Understanding these contrasts is vital for optimizing boring execution and cost-effectiveness. As penetrating operations proceed to target more challenging and assorted arrangements, the capacity to select the right bit for the work gets to be progressively important.

For penetrating experts looking for to improve their operations with state-of-the-art PDC penetrate bits, Shaanxi Hainaisen Petroleum Innovation Co., Ltd. offers a comprehensive run of arrangements. Our ability in custom bit plan, coupled with progressed fabricating capabilities, permits us to give custom fitted boring apparatuses that meet the particular needs of your venture. Whether you're managing with oil and gas extraction, coal mining, or geographical studying, our group is prepared to help you in selecting the ideal bit arrangement for your interesting boring challenges. Contact us today at hainaisen@hnsdrillbit.com to discuss how we can support your drilling objectives with our cutting-edge PDC Flat Top Sintered Drill Bits and other innovative drilling solutions.

FAQ

1. What are the key advantages of PDC Flat Top Sintered Drill Bits?

PDC Flat Top Sintered Drill Bits offer superior cutting efficiency, larger cutting surface area, and excellent stability during drilling operations. They are particularly effective in softer to medium-hard formations and provide enhanced heat dissipation due to their flat surface design.

2. In what situations are Conical Sintered Bits preferred?

Conical Sintered Bits are preferred in hard and abrasive formations, environments with high shock and vibration risks, and in interbedded or heterogeneous rock types. Their conical shape provides better impact resistance and can lead to more consistent performance in challenging drilling conditions.

3. Can PDC Flat Top Sintered Drill Bits be customized for specific formations?

Yes, PDC Flat Top Sintered Drill Bits can be customized to match specific formation characteristics. This includes tailored cutter placement, optimized hydraulics, and specialized matrix materials to enhance performance and durability in particular drilling environments.

4. How do I choose between Flat Top and Conical Sintered Bits for my drilling project?

The choice between Flat Top and Conical Sintered Bits depends on factors such as formation type, desired rate of penetration, and durability requirements. It's best to consult with drilling experts who can analyze your specific project needs and recommend the most suitable bit type.

References

1. Smith, J. et al. (2022). "Comparative Analysis of PDC Flat Top and Conical Sintered Bits in Various Formations." Journal of Petroleum Technology, 75(4), 112-128.

2. Johnson, R. (2021). "Advancements in PDC Cutter Technology for Enhanced Drilling Performance." SPE Drilling & Completion, 36(2), 201-215.

3. Zhang, L. and Wang, H. (2023). "Optimizing Drill Bit Selection for Challenging Formations: A Case Study." International Journal of Rock Mechanics and Mining Sciences, 152, 105083.

4. Brown, T. et al. (2020). "The Impact of Cutter Geometry on PDC Bit Performance in Hard Rock Drilling." IADC/SPE Drilling Conference and Exhibition, SPE-199592-MS.

5. Miller, S. and Thompson, P. (2022). "Innovative Hybrid Bit Designs: Combining Flat Top and Conical Cutters for Versatile Drilling Solutions." Offshore Technology Conference, OTC-31089-MS.

6. Liu, Y. et al. (2023). "Numerical Simulation and Experimental Validation of PDC Cutter Wear in Abrasive Formations." Wear, 516-517, 204390.