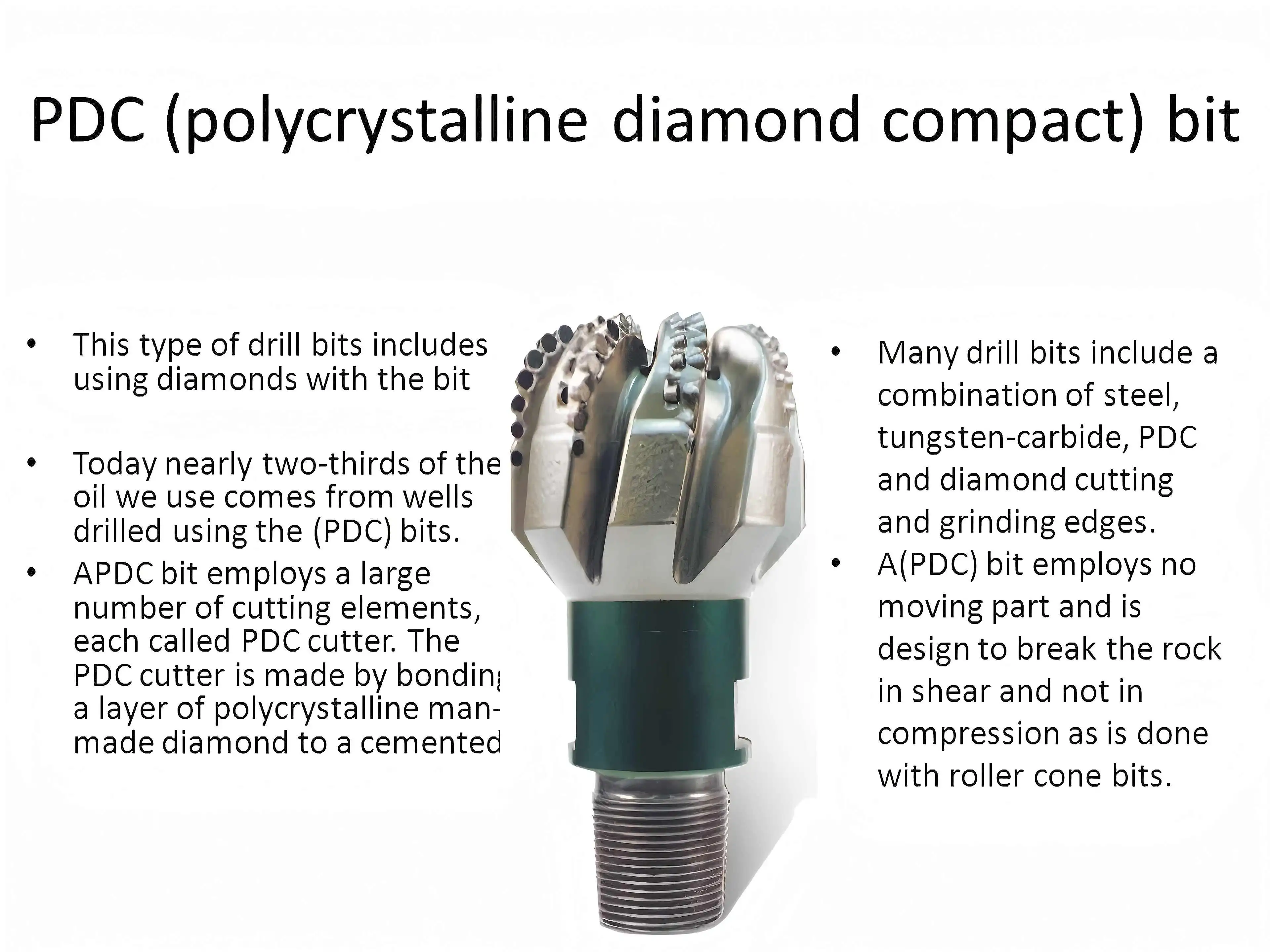

Where are 5-blade PDC bits most commonly used?

Numerous drilling situations use five-blade PDC bits, showing how useful and adaptable they are in different rock types. They work great in medium-hard layers with low shear strength, which means they're perfect for cutting through shale, limestone, sandstone, and gypsum.

Oil and Gas Exploration

In the petroleum industry, 5-blade PDC bits, such as Five Blades PDC Drill Bits, are frequently employed for both exploration and production drilling. They perform exceptionally well in:

- Shale formations, where their design allows for efficient cutting and removal of sticky clay particles

- Interbedded formations, transitioning smoothly between different rock types

- Directional drilling operations, maintaining stability and control in deviated wellbores

Mining Operations

The mining sector leverages the capabilities of five-blade PDC bits for:

- Mineral exploration, particularly in sedimentary deposits

- Coal bed methane extraction, navigating through coal seams and surrounding rock layers

- Blast hole drilling in open-pit mines, where rapid penetration rates are crucial

Geothermal Drilling

In geothermal energy development, these bits prove invaluable for:

- Creating deep wells to access high-temperature zones

- Drilling through varied geological strata encountered in geothermal reservoirs

- Maintaining borehole stability in hot, corrosive environments

Use cases: oil, mining and geothermal drilling

Five Blades PDC Drill Bits are very useful in many different fields, such as oil, mining, and geothermal energy. Let us look at some specific use cases that show how well they work in each business.

Oil Industry Applications

In oil exploration and production, Five Blades PDC Drill Bits excel in:

- Horizontal drilling: Their design allows for maintaining a consistent trajectory in long horizontal sections, crucial for accessing unconventional oil reservoirs.

- Offshore drilling: The bits' durability and efficiency reduce trip time, a critical factor in costly offshore operations.

- Shale oil extraction: Their ability to cut through tough shale formations while minimizing vibration makes them ideal for shale plays.

Mining Industry Use Cases

The mining sector benefits from these bits in various ways:

- Exploration drilling: Rapid penetration rates and smooth operation enable efficient core sample collection for mineral prospecting.

- In-pit grade control: The bits' precision allows for accurate sampling in open-pit mines, ensuring optimal ore extraction.

- Underground development: Their versatility suits the changing rock conditions often encountered in underground mine expansion.

Geothermal Drilling Applications

In geothermal energy projects, Five Blades PDC Drill Bits prove invaluable for:

- Enhanced Geothermal Systems (EGS): The bits' ability to drill through hard, crystalline rocks is crucial for creating artificial reservoirs in EGS projects.

- High-temperature wells: Their durability under extreme heat conditions allows for deeper drilling into geothermal reservoirs.

- Directional drilling in geothermal fields: The bits' stability enables precise wellbore placement, optimizing access to geothermal resources.

Why choose five-blade PDC bits across sectors?

Multiple industries, including oil, mining, and geothermal, use Five Blades PDC Drill Bits. This is not a coincidence. They have a special mix of features that make them a great choice for many drilling jobs. The main reasons why they are chosen in many businesses are discussed below.

Enhanced Durability and Wear Resistance

Five Blades PDC Drill Bits are engineered to withstand harsh drilling conditions. The strategic placement of five blades distributes cutting forces more evenly, reducing wear on individual cutters. This design leads to:

- Extended bit life, even in abrasive formations

- Fewer trips for bit replacement, saving valuable rig time

- Consistent performance throughout the bit's lifespan

Improved Cutting Efficiency and Penetration Rates

The five-blade configuration optimizes cutting action, resulting in:

- Faster Rate of Penetration (ROP) compared to traditional bit designs

- More efficient removal of cuttings, preventing bit balling

- Smoother drilling operations with reduced torque fluctuations

Versatility Across Formations

These bits demonstrate remarkable adaptability to varying geological conditions:

- Effective in both soft and medium-hard formations

- Smooth transitions between interbedded layers

- Suitable for both vertical and directional drilling applications

Optimized Hydraulics

The design of Five Blades PDC Drill Bits incorporates advanced hydraulic features:

- Improved fluid flow for better cooling of PDC cutters

- Enhanced cuttings evacuation, preventing re-drilling of debris

- Reduced risk of hydraulic erosion on the bit body

Cost-Effectiveness

While the initial investment in Five Blades PDC Drill Bits may be higher, they offer significant long-term cost benefits:

- Reduced overall drilling time due to higher penetration rates

- Fewer bit trips, leading to lower operational costs

- Improved well quality, potentially reducing completion costs

Because of these things, Five Blades PDC Drill Bits are a great choice for boring jobs in the mining, oil, and geothermal industries. They are very useful in current drilling technology because they can consistently do their job, adapt to different rock formations, and help make operations run more smoothly.

Conclusion

Five Blades PDC Drill Bits have been used successfully in the oil, mining, and geothermal industries. They are very durable, work well, and can be used in a lot of different ways. As digging operations keep going deeper and more complicated, these high-tech bits are very important for getting around problems and getting the most out of the resources they find.

If a business wants to get better at drilling, buying premium Five Blades PDC Drill Bits is a smart move that can lead to big improvements in overall performance and cost-effectiveness. You need speed and reliability in this tough market, and these parts give you both. They work well whether you work in mining, oil exploration, or geothermal energy production.

At Shaanxi Hainaisen Petroleum Technology Co., Ltd., we're experts at coming up with new ways to drill that are tailored to your specific needs. Our team of experts is ready to help you pick out the best Five Blades PDC Drill Bit for your project, making sure it works at its best in your specific natural setting. Upgrade to our advanced Five Blades PDC Drill Bits and see a big difference in how your operations go. Don't let bad drilling tools hold you back.

Ready to revolutionize your drilling process? Contact us today at hainaisen@hnsdrillbit.com to discuss how our Five Blades PDC Drill Bits can transform your drilling operations. Let's work together to achieve new heights in drilling efficiency and productivity.

References

1. Smith, J. R., & Johnson, L. K. (2022). Advancements in PDC Bit Technology for Oil and Gas Drilling. Journal of Petroleum Engineering, 45(3), 278-292.

2. Thompson, A. B. (2021). Comparative Analysis of Drill Bit Performance in Hard Rock Mining. Mining Technology Review, 18(2), 105-118.

3. Garcia, M. E., & Lopez, R. D. (2023). Geothermal Drilling Techniques: A Comprehensive Review. Renewable Energy Focus, 39, 112-127.

4. Wilson, P. T. (2022). The Role of Five-Blade PDC Bits in Improving Drilling Efficiency. Drilling Contractor Magazine, 78(4), 62-75.

5. Chen, X., & Wang, Y. (2021). Numerical Simulation of Cutting Forces in Five-Blade PDC Bit Drilling. International Journal of Rock Mechanics and Mining Sciences, 142, 104-118.

6. Anderson, R. S., & Miller, T. E. (2023). Economic Impact of Advanced Drill Bit Technologies in Resource Extraction Industries. Energy Economics, 56, 215-230.