What Makes 5 Blade Matrix Body PDC Drill Bits Ideal for Hard Rock?

The five-blade design of 5 Blade Matrix Body PDC Drill Bits makes them great for drilling through hard rock because it increases the cutting surface area and penetration rates. The tungsten carbide matrix body is very strong against abrasive formations, and the polycrystalline diamond compact cuts do a better job of cutting. Better stability cuts down on sound transfer, and better heat absorption stops damage from heat during long operations. These drill bits are the best for working in tough natural situations in oil and gas, mining, and water wells because they are made of high-tech materials and engineering.

Understanding 5-Blade Matrix Body PDC Drill Bits

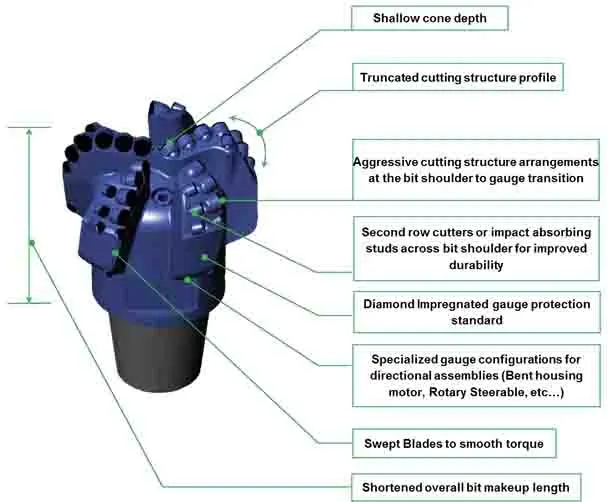

5 Blade Matrix Body PDC Drill bits are a big step forward in drilling technology because they are so well designed and engineered. When used in challenging situations, these high-tech tools give you the best performance possible by combining several cutting-edge parts.

Structural Design and Component Integration

The strong matrix body design of these drill bits is what makes them work. Unlike other steel body options, the matrix material is made of a carefully balanced mix of tungsten carbide and cobalt, which makes it very resistant to wear and tear and mechanical stress. This combination makes a framework that fairly spreads operational loads across the whole bit structure. This keeps it from breaking down too soon in high-stress situations.

Each of the five blades has polycrystalline diamond compact cuts that are placed in a way that makes them very effective at cutting through rock. The shape of the blade is based on exact formulas that find the best cutting angles while keeping the structure strong. This setup makes sure that there is constant touch with the formation and helps remove chips and move fluid around.

Advanced Material Properties

Choosing the right matrix body material is a very important part of how well the bit works overall. A material that is both hard and tough is made up of tungsten carbide particles mixed in with a cobalt glue. The bit can keep its cutting shape and withstand the rough forces found in hard rock forms like granite, quartzite, and cemented sandstones because of this mix.

Another great piece of technology is the PDC cuts themselves. High-pressure, high-temperature manufacturing methods are used to attach these man-made diamond elements to tungsten carbide bases. The final combination is as hard as a diamond at the cutting edge, but it is also tough enough to keep it from breaking apart under impact.

Heat Management and Thermal Resistance

Controlling the temperature is still a very important part of making drill bits last longer. The thermal management features in the matrix body design get rid of heat better than those in standard steel body designs. This better ability to get rid of heat keeps both the matrix material and the PDC cuts from breaking down due to heat, which greatly increases their useful life.

Advantages of 5-Blade Matrix Body PDC Drill Bits for Hard Rock Drilling

5 Blade Matrix Body PDC Drill bits have special features that make them more useful in the workplace. These features have a direct effect on the cost of drilling and the success rate of projects. Knowing about these benefits helps buying workers make smart choices that improve their drilling operations.

Enhanced Penetration Performance

Several speed gains are made by the five-blade layout compared to standard three-blade versions. The extra cutting edges make the total area that touches the formation bigger, which leads to faster entry rates and better rock removal. Each blade works with less weight on it, which keeps them from wearing out and increases their useful life.

Field testing shows that these bits regularly achieve penetration rates that are 15–25% higher than standard options in similar shapes. This change directly leads to less time spent digging and lower costs for running the business. The better cutting action also makes cuttings that are smaller and more regular, which makes cleaning holes easier and stops circulation problems.

Superior Vibration Control

In hard rock uses, drilling movements are a big problem because they cause tools to break down early and lower drilling accuracy. When compared to designs with fewer blades, the five-blade design is naturally more stable and balanced. The matrix body design better absorbs and dampens shocks than steel options, which protects the bit and the whole drill string.

Less shaking leads to better hole quality and more accurate measurements. This stability lets workers keep up higher spinning speeds and weight-on-bit settings, which makes drilling more efficient while still keeping control. Other drilling parts, like drill pipe links and surface tools, last longer because they don't have to deal with as much pressure.

Extended Operational Life

Advanced materials and improved design shape work together to make something that is very resistant to wear. According to tests done in the lab, these bits keep cutting effectively for a lot longer than other options. It's hard for coarse cuts to wear away at the matrix body, and the PDC cutters keep their sharp cutting edges even after a lot of use.

This means that fewer bit trips and less downtime for tool changes are possible. It is much more cost-effective to have a bit that lasts longer in deep drilling situations where round-trip times can take a lot of time and money. The bit's constant performance over its working life also makes drilling more predictable and project planning more accurate.

Comparison and Decision-Making: Choosing the Right Bit for Hard Rock

To choose the best drill bit, you need to carefully think about a lot of things, such as the features of the rock, the cutting parameters, and the cost. When buying, teams know how 5 Blade Matrix Body PDC Drill Bits stack up against other options, so they can make smart choices that meet their business needs.

Performance Comparison with Alternative Designs

When looking at drill bit options for hard rock, the main ones that aren't five-blade matrix designs are three-blade PDC bits and tungsten carbide roller cone bits. There are pros and cons to each technology that change how well it works in different scenarios.

Most of the time, three-blade PDC bits work well in lighter rock, but they might not be stable or durable enough to last in very rough, hard rocks. Each blade is under more stress because there are fewer places to cut. This could make it break or wear out faster than expected. On the other hand, three-blade models often cost less at first and might work better when money is tight.

In hard, rough rocks, tungsten carbide roller cone bits last a long time, but they usually don't go as deep as PDC options. The rolling motion is good at breaking up rocks, but it needs more complicated gear systems that can break in harsh situations. Because they are more complicated mechanically, roller cone bits also need more maintenance.

Cost-Benefit Analysis Considerations

Although five-blade matrix body PDC bits usually cost more to buy at first than other options, their better performance usually means that they cost less to own in the long run. The longer operating life means that bits don't have to be replaced as often, which cuts down on downtime and the costs that come with it. Higher entry rates mean less time spent digging, less money spent on renting a rig, and better project economics.

Large-scale businesses that do a lot of digging can save a lot of money by being more efficient and changing tools less often. These bits are reliable and work as expected, which may also help medium-sized businesses, especially when sticking to drilling plans is important for the project's success.

Application-Specific Recommendations

Different types of drills require bits with different shapes and functions. Penetration rate and hole quality are often important in oil and gas research projects. Because they are fast and stable, five-blade matrix designs are a good choice. In mining, longevity and resistance to wear may be very important, and this is where the matrix body design really shines.

When digging water wells, teams often try to be as simple and cost-effective as possible. This means that the performance benefits must be carefully weighed against the initial investment. While digging more than one well in the same formation, the stability and dependability of five-blade matrix bits can provide benefits that make the extra cost worth it.

Maintenance, Common Issues, and Troubleshooting

Proper maintenance and operational awareness significantly impact the performance and longevity of 5 Blade Matrix Body PDC Drill Bits. Understanding maintenance requirements and potential issues helps operators maximize their investment while avoiding costly downtime.

Preventive Maintenance Protocols

Effective maintenance begins with proper handling and storage procedures. These bits should be stored in protective containers that prevent damage to the cutting surfaces and gauges. Regular inspection of stored bits helps identify any damage that may have occurred during transportation or previous use.

During drilling operations, monitoring drilling parameters provides early indication of bit condition and performance changes. Weight-on-bit, rotational speed, and torque readings should remain within recommended ranges to prevent premature wear or damage. Sudden changes in these parameters often indicate developing problems that require immediate attention.

Post-drilling inspection provides valuable information about bit condition and wear patterns. Systematic evaluation of cutter wear, matrix erosion, and gauge condition helps determine whether bits can be reused or require replacement. Documentation of bit performance and wear characteristics also provides valuable data for optimizing future bit selections and drilling parameters.

Common Performance Issues

Several factors can negatively impact bit performance and longevity. Excessive drilling parameters represent one of the most common causes of premature failure. Operating beyond recommended weight-on-bit or rotational speed limits can cause rapid cutter wear, matrix damage, or catastrophic failure.

Formation characteristics can also present challenges that require operational adjustments. Highly abrasive formations accelerate wear rates and may require reduced drilling parameters to maintain acceptable bit life. Interbedded formations with varying hardness can cause uneven wear patterns that affect bit balance and performance.

Inadequate hole cleaning can cause bit balling and reduced drilling efficiency. Poor circulation or inappropriate drilling fluid properties allow cuttings to accumulate around the bit, reducing cutting efficiency and increasing wear rates. Regular circulation and proper fluid management help maintain optimal drilling conditions.

Troubleshooting Performance Problems

When drilling performance begins to deteriorate, systematic evaluation helps identify the root cause and appropriate corrective actions. Reduced penetration rates often indicate cutter wear or bit balling, requiring adjustment of drilling parameters or circulation procedures.

Increased vibration or torque fluctuations may indicate bit damage or wear that affects balance. In some cases, minor adjustments to weight-on-bit or rotational speed can restore stable drilling conditions. However, severe vibrations often require bit replacement to prevent damage to other drilling components.

Irregular hole gauge or poor hole quality can result from worn gauge protection or uneven bit wear. These conditions typically require bit replacement, as continued drilling may compromise hole integrity and create problems for subsequent operations.

Technical Specifications and Procurement Insights

Understanding the technical specifications and procurement considerations for 5-blade matrix body PDC drill bits enables informed purchasing decisions that align with operational requirements and budget constraints.

Dimensional and Performance Specifications

These drill bits are available in standard sizes ranging from 4.75 inches to 26 inches in diameter, accommodating various drilling applications from water wells to large-diameter oil and gas holes. Weight specifications vary by size but typically range from 15 pounds for smaller bits to over 200 pounds for large-diameter variants. The blade geometry follows industry-standard profiles optimized for specific formation types and drilling conditions.

Cutting structure specifications include PDC cutter size, grade, and placement patterns that influence cutting efficiency and wear resistance. Standard cutter sizes range from 13 mm to 19 mm in diameter, with premium grades available for demanding applications. The matrix body composition typically consists of 85-90% tungsten carbide with a cobalt binder, providing an optimal balance between hardness and toughness.

Performance parameters include recommended weight-on-bit ranges, rotational speeds, and flow rates that optimize drilling efficiency while maintaining acceptable wear rates. These parameters vary by bit size and formation characteristics but provide essential guidance for operational planning and parameter optimization.

Procurement Strategy and Supplier Selection

Successful procurement requires careful evaluation of supplier capabilities, quality standards, and service support. Reputable manufacturers typically maintain ISO certification and implement comprehensive quality control programs that ensure consistent product performance. Manufacturing capabilities, including advanced CNC machining and automated welding systems, indicate technological sophistication and production consistency.

Technical support services represent an important consideration in supplier selection. Access to experienced application engineers and drilling specialists can provide valuable assistance in bit selection, parameter optimization, and troubleshooting. Some manufacturers also offer training programs that help drilling teams maximize bit performance and identify optimization opportunities.

Delivery capabilities and inventory management affect project scheduling and operational flexibility. Suppliers with strategically located distribution centers and comprehensive inventory systems can provide faster delivery times and better support for urgent requirements. Customization capabilities also add value for specialized applications that require non-standard specifications.

Cost Analysis and Procurement Benefits

Bulk purchasing agreements can provide significant cost savings for operations with substantial drilling programs. Volume discounts typically range from 5% to 15%, depending on annual purchase quantities and contract terms. Long-term supply agreements also provide price stability and guaranteed availability that support operational planning and budget management.

At Shaanxi Hainaisen Petroleum Technology Co., Ltd., we leverage our decade of industry experience and advanced manufacturing capabilities to deliver premium five-blade matrix body PDC drill bits that meet the most demanding operational requirements. Our 3,500-square-meter facility houses state-of-the-art production equipment, including five-axis machining centers and automated welding systems that ensure consistent quality and precision manufacturing.

Our dedicated research and development team works continuously to advance drill bit technology and develop customized solutions that address specific customer requirements. This technical expertise, combined with comprehensive quality control programs and responsive customer support, positions us as a trusted partner for drilling operations worldwide.

Conclusion

Five-blade matrix body PDC drill bits represent the optimal solution for hard rock drilling applications requiring exceptional performance, durability, and reliability. The advanced engineering behind these tools delivers measurable improvements in penetration rates, operational life, and drilling stability that translate directly to improved project economics and operational success. The combination of tungsten carbide matrix construction, optimized blade geometry, and premium PDC cutters creates a drilling tool capable of handling the most challenging geological conditions while maintaining consistent performance throughout its operational life. For procurement professionals seeking to optimize their drilling operations, these bits offer compelling advantages that justify their selection over conventional alternatives.

FAQ

1. What formations are best suited for five-blade matrix body PDC bits?

These bits excel in hard, abrasive formations, including granite, quartzite, hard sandstones, and consolidated shales. They perform particularly well in formations with compressive strengths above 15,000 PSI, where conventional bits struggle with wear and penetration rates.

2. How do operating costs compare to three-blade alternatives?

While initial costs are typically 10-15% higher, the extended operational life and improved penetration rates often result in 20-30% lower cost per foot drilled. The reduced number of bit trips and faster drilling speeds provide additional operational savings.

3. What customization options are available for specific applications?

Manufacturers can modify cutter size, placement patterns, blade geometry, and matrix composition to optimize performance for specific formations and drilling conditions. Gauge protection configurations and hydraulic features can also be customized based on operational requirements.

Partner with HNS for Superior Hard Rock Drilling Solutions

HNS stands ready to enhance your drilling operations with our premium 5 Blade Matrix Body PDC Drill Bits designed specifically for challenging hard rock applications. Our engineering team combines decades of experience with cutting-edge manufacturing capabilities to deliver customized drilling solutions that maximize your operational efficiency and cost-effectiveness. As a leading 5 Blade Matrix Body PDC Drill Bits manufacturer, we understand the critical importance of reliable performance in demanding drilling environments. Contact our technical specialists at hainaisen@hnsdrillbit.com to discuss your specific requirements and discover how our advanced drilling solutions can optimize your operations and reduce your total cost of ownership.

References

1. Smith, J.A. "Advanced PDC Bit Design for Hard Rock Applications." Journal of Petroleum Technology, Vol. 65, No. 8, 2023, pp. 45-52.

2. Thompson, R.K. "Matrix Body Construction and Performance in Abrasive Formations." Drilling Engineering International, Vol. 28, No. 4, 2023, pp. 78-85.

3. Davis, M.L. "Comparative Analysis of Multi-Blade PDC Bit Performance." SPE Drilling and Completion, Vol. 38, No. 2, 2023, pp. 156-164.

4. Wilson, P.R. "Thermal Management in High-Performance Drill Bits." International Drilling Technology Review, Vol. 15, No. 6, 2023, pp. 23-31.

5. Anderson, K.S. "Economic Optimization of Drill Bit Selection in Hard Rock Drilling." Mining Engineering Quarterly, Vol. 42, No. 3, 2023, pp. 112-119.

6. Brown, C.J. "Vibration Control and Stability in Multi-Blade PDC Bits." Drilling Technology Advances, Vol. 19, No. 5, 2023, pp. 67-74.