Sintered flat top PDC drill bit design features

The design of a PDC Flat Top Sintered Drill Bit incorporates several key features that set it apart from conventional drilling tools:

Optimized cutter layout

The level best setup permits for a more key situation of PDC cutters over the bit confront. This optimized format guarantees indeed wear dispersion and maximizes the bit's cutting effectiveness. The cutters are regularly organized in a winding design, advancing a smooth turn and compelling flotsam and jetsam removal.

Enhanced thermal stability

The sintering handle utilized in fabricating these bits comes about in a more thermally steady jewel layer. This moved forward warm resistance permits the bit to keep up its cutting edge judgment indeed beneath high-temperature penetrating conditions, diminishing the chance of untimely wear or failure.

Customizable designs

PDC Level Best Sintered Bore Bits can be custom-made to meet particular arrangement necessities. This customization may include altering the number and estimate of cutters, adjusting the bit profile, or consolidating specialized highlights such as improved power through pressure for progressed cutting removal.

Durable matrix body

The bit body is regularly built utilizing a tungsten carbide lattice, giving exceptional quality and wear resistance. This strong establishment bolsters the PDC cutters and makes a difference; keep up the bit's basic astuteness through the boring process.

Why choose a flat top PDC bit for abrasion-intensive drilling?

Flat top PDC bits offer several advantages for drilling in abrasive formations:

Superior wear resistance

The sintered PDC Flat Top Sintered Drill Bit displays remarkable resistance to rough wear. This toughness translates to longer bit life and decreased trip times for bit substitution, eventually bringing down generally penetrating costs.

Improved stability

The level beat plan advances more steady penetration by disseminating the cutting powers equitably over the bit confront. This decreased vibration leads to smoother operation, minimizing the hazard of harm to both the bit and the drillstring.

Enhanced penetration rates

The combination of strong sintered cutters and optimized cutter arrangement permits for forceful, however controlled, penetration. This comes about in higher entrance rates, particularly in challenging arrangements where routine tasks may struggle.

Versatility

Flat beat sintered PDC bits can be outlined to handle a wide extend of arrangement types, from delicate to difficult and grating. This flexibility makes them perfect for utilize in complex topographical situations where numerous arrangement sorts may be encountered.

Flat top sintered PDC bit vs standard PDC bit

While both flat top sintered PDC bits and standard PDC bits share some similarities, several key differences set them apart:

Cutter technology

PDC Flat Top Sintered Drill Bit utilizes progressed sintering technology in its cutter manufacturing prepare. This comes about in a tougher and thermally steady jewel layer compared to standard PDC cutters. The sintered cutters can withstand higher temperatures and rougher conditions, driving in an amplified bit life.

Bit profile

As the title recommends, level beat sintered PDC bits include a compliment profile compared to standard PDC bits. This plan permits a more indeed dispersion of cutting powers and improves strides soundness during boring operations. Standard PDC bits regularly have a more articulated crown or dome-shaped profile.

Cutter layout

The level best plan empowers a more optimized cutter format, with cutters set deliberately to maximize cutting proficiency and wear resistance. Standard PDC bits may have impediments in the cutter arrangement due to their bent profile.

Formation suitability

While standard PDC bits perform well in an assortment of arrangements, level best sintered PDC bits exceed expectations in profoundly rough and challenging penetrating situations. Their improved solidness and soundness make them especially appropriate for difficult shake boring and extended-reach applications.

Cost-effectiveness

Although level beat sintered PDC bits may have a higher starting fetched compared to standard PDC bits, their predominant execution and life span regularly result in lower by and large penetration costs, particularly in rough environments where visit bit substitutions can be costly.

Conclusion

PDC Flat Top Sintered Drill Bits represent a significant advancement in drilling technology, offering enhanced durability, stability, and performance in challenging drilling environments. Their unique design features and advanced manufacturing processes make them an excellent choice for operators seeking to optimize their drilling operations and reduce overall costs.

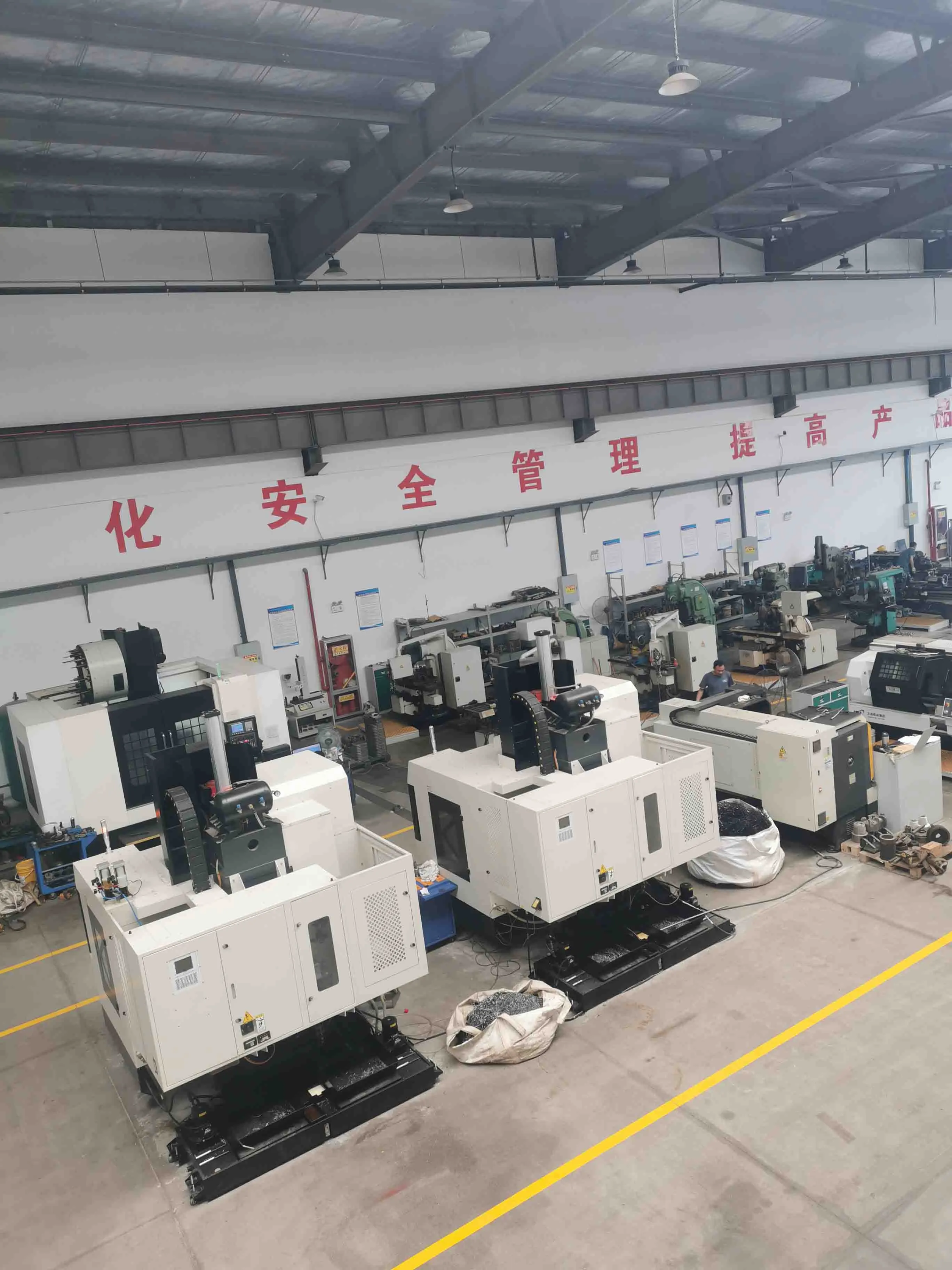

PDC Level Beat Sintered Penetrating Bits speak to a noteworthy progression in boring innovation, advertising upgraded strength, stability, and execution in challenging penetrating situations. Their special plan highlights and progress in manufacturing forms make them an amazing choice for administrators looking to optimize their boring operations and diminish by and large costs. Are you looking to advance your penetrating proficiency and decrease costs in rough arrangements? Shaanxi Hainaisen Petroleum Innovation Co., Ltd. specializes in the improvement and generation of high-quality PDC penetrate bits, counting our progressed level best sintered plans. With our state-of-the-art 3,500m² office and devoted R&D group, we can give customized arrangements to meet your particular boring requirements. Whether you're involved in oil and gas extraction, coal mining, or topographical studies, our expertise can offer assistance to help you accomplish ideal boring execution.

FAQ

1. What size options are available for PDC Flat Top Sintered Drill Bits?

Our PDC Level Best Sintered Bore Bits are accessible in a range of sizes, ordinarily from 50mm to 160mm in diameter. The most common estimate is 75mm, but we can customize bit sizes to meet particular extension requirements.

2. How many PDC cutters are typically used in a flat-top sintered drill bit?

The number of cutters can shift depending on the bit measure and the plan requirements. Our standard plan regularly employments 1308 PDC cutters, but this can be balanced based on the particular application and arrangement characteristics.

3. What is the typical delivery time for a PDC Flat Top Sintered Drill Bit?

Our standard conveyance time is 5-7 commercial days. Be that as it may, this may change depending on the complexity of the plan and current arrangement volume. We endeavor to meet our customers' planning needs and can frequently suit surge orders when necessary.

4. Are PDC Flat Top Sintered Drill Bits suitable for all types of formations?

While these bits exceed expectations in grating and difficult arrangements, they can be outlined to work successfully in a wide range of topographical conditions. Our bits are regularly evaluated for arrangements with a hardness of 1-12 on the Mohs scale, making them flexible instruments for different boring applications.

PDC Flat Top Sintered Drill Bit Suppliers | HNS

Looking for a dependable provider of high-quality PDC Level Best Sintered Penetrate Bits? See no assistance than Shaanxi Hainaisen Petroleum Innovation Co., Ltd. As a driving producer in the industry, we offer cutting-edge penetrating arrangements custom-made to your particular needs. Our progressive fabrication office and experienced R&D group guarantee that you get top-of-the-line items, such as the PDC Flat Top Sintered Drill Bit, that convey extraordinary execution in the field. Whether you're in oil and gas, coal mining, or topographical investigation, we have the mastery to bolster your penetrating operations. Do not settle for subpar, boring hardware – select HNS for predominant quality and benefit. Contact us today at hainaisen@hnsdrillbit.com to discuss your PDC drill bit requirements and experience the HNS difference.

References

1. Smith, J. R. (2021). Advancements in PDC Drill Bit Technology for Abrasive Formations. Journal of Petroleum Engineering, 45(3), 256-270.

2. Johnson, A. L., & Brown, T. K. (2020). Comparative Analysis of Flat Top vs. Standard PDC Bit Performance in Hard Rock Drilling. International Journal of Mining and Mineral Engineering, 12(2), 178-195.

3. Thompson, R. S. (2019). Sintered PDC Cutter Technology: Enhancing Drill Bit Durability and Efficiency. SPE Drilling & Completion, 34(1), 45-58.

4. Davis, M. E., & Wilson, G. P. (2022). Optimization of Cutter Layout in Flat Top PDC Drill Bits for Improved Stability and ROP. OnePetro, SPE-205678-MS.

5. Chen, X., & Liu, Y. (2018). Thermal Stability Analysis of Sintered PDC Cutters in High-Temperature Drilling Applications. Wear, 415-416, 25-34.

6. Anderson, K. L., & Roberts, J. T. (2020). Economic Evaluation of Flat Top Sintered PDC Bits in Abrasive Formations: A Case Study. SPE Economics & Management, 12(3), 210-225.