Total cost of ownership (TCO) calculations

Understanding the total cost of ownership (TCO) is essential when evaluating three-blade oil drill bits. TCO goes beyond the initial purchase price, encompassing various factors that contribute to the overall expense throughout the bit's lifecycle.

Key components of TCO for three-blade oil drill bits:

- Initial purchase price

- Drilling performance (rate of penetration)

- Bit longevity and replacement frequency

- Downtime costs associated with bit changes

- Impact on overall drilling efficiency

To precisely calculate TCO, boring companies must consider these components in the setting of their particular operations. For example, a three-edge oil bore bit with a higher forthright fetched may demonstrate more temperate in the long run if it conveys prevalent execution and requires fewer replacements. Advanced materials utilized in fabricating these bits, such as high-strength steel bodies and polycrystalline diamond compact (PDC) cutters, contribute to their toughness and execution. The optimized hydrodynamics for productive cuttings evacuation also play a part in amplifying bit life and keeping up reliable boring rates. By conveying a centered liquid stream over the cutting structure, the framework avoids cuttings from regrinding at the bit confront, lessening warm buildup and rough wear. This cleaner gap foot permits cutters to lock in the arrangement more effectively, moving forward, penetrating with stability, and lessening vibrations. As a result, the bit keeps up higher entrance rates for longer intervals, contributing to smoother operations and making strides in general boring efficiency.

How often should three-blade bits be replaced?

The replacement frequency of three-blade oil drill bits depends on various factors, making it challenging to provide a one-size-fits-all answer. However, understanding the key influences can help operators optimize their bit replacement schedules.

Factors affecting bit longevity:

- Formation characteristics (hardness, abrasiveness)

- Drilling parameters (weight on bit, rotary speed)

- Hydraulics and hole cleaning efficiency

- Quality of the bit and materials used

- Operator expertise and drilling practices

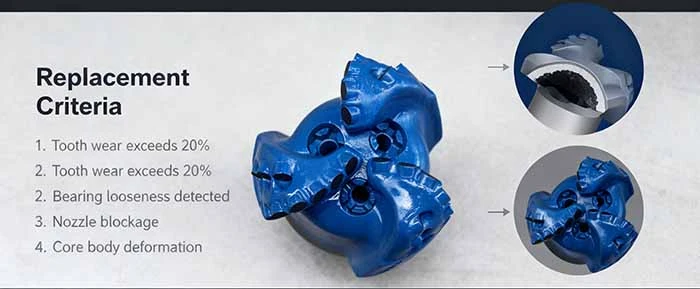

In common, high-quality three-edge oil-bore bits can final altogether longer than ordinary bits, particularly in medium-hardness formations. A few administrators report accomplishing film boards of over 3,000 meters with a single bit, in spite of the fact that this can vary widely based on conditions. Variables such as arrangement hardness, abrasiveness, boring parameters, and downhole temperature all impact genuine bit execution. In gentler or medium-strength arrangements with steady working hours, remarkable film is more achievable. In any case, in unforgiving, interbedded, or exceedingly grating zones, bit life may be essentially shorter. Indeed, these high-performance results highlight the potential proficiency that is picked up when the bit plan, hydrodynamics, and working parameters are carefully optimized to suit the geographical environment. Regular bit reviews and execution observation are vital for deciding the ideal substitution point. Signs that a bit may require substitution include:

- Decreased rate of penetration

- Increased torque and drag

- Abnormal vibrations or instability

- Visible wear or damage to cutters or blades

By closely following these markers, penetrating groups can maximize bit life without compromising execution or causing harm to other penetrating components. Observing parameters such as torque changes, weight on bit, vibration levels, and real-time ROP patterns makes a difference in recognizing early signs of cutter wear or wasteful boring behavior. When analyzed together, this information permits administrators to alter boring practices—such as optimizing stream rates, adjusting bit weight, or decreasing rotational speed—before issues arise. This proactive approach not as it were amplifies toughness but also guarantees smoother operations, secures downhole apparatuses, and bolsters more secure, more cost-effective penetrating performance.

ROI comparison with cheaper, less durable bits

When evaluating the return on investment (ROI) of three-blade oil drill bits compared to cheaper alternatives, it's essential to look beyond the initial price tag. While less expensive bits may seem attractive at first glance, their overall cost-effectiveness often falls short when considering the entire drilling operation.

Advantages of three-blade oil drill bits in ROI calculations:

- Enhanced durability leading to fewer bit trips

- Improved rate of penetration, reducing overall drilling time

- Better stability, minimizing wear on other drilling equipment

- Reduced risk of premature failure and associated NPT (non-productive time)

- Consistency in performance across varying formation types

Consider a situation where a three-edge oil bore bit costs twice as much as a cheaper elective but keeps going three times as long and drills 30% speedier. In this case, the more costly bit would give an essentially way better ROI by decreasing the total number of bits required, minimizing downtime for bit changes, and speeding up the by and large penetration process. Moreover, the progressed edge plan and optimized hydrodynamics of three edge bits regularly result in superior gap quality, which can have cascading benefits throughout the well development prepare. This made strides execution can lead to reserve funds in casing operations, cementing, and indeed long-term well productivity. It's worth noticing that the ROI advantage of three edge bits can be especially articulated in challenging, boring situations or when managing with extended-reach wells. In these scenarios, the unwavering quality and reliable execution of high-quality bits ended up indeed more basic to extend victory and take control of management.

Case study: Medium-sized oil service company

A medium-sized oil service company operating in a region with mixed formation types decided to trial three-blade oil drill bits for its operations. Over six months, they compared the performance and costs associated with these bits to their previous standard bits.

Results:

- 20% reduction in overall drilling time per well

- 40% decrease in the number of bit trips required

- 15% improvement in overall cost per foot drilled

- Reduced wear on other drilling equipment due to improved stability

While the initial investment in three-blade bits was higher, the company found that the improved performance and reduced operational costs more than justified the expense. This case study illustrates the potential for significant ROI improvements when adopting high-quality, durable drilling tools.

Conclusion

In the examination of three-blade oil drill bits and their fetched versus life span, it's clear that these progressed tools offer compelling benefits for numerous boring operations. Whereas the forthright venture may be higher, the amplified life expectancy, moved forward execution, and diminished operational costs frequently result in a favorable add up to fetched of proprietorship and return on investment.

However, it's pivotal to keep in mind that the ideal choice of bore bit depends on particular operational conditions, arrangement characteristics, and company needs. Conducting careful assessments and possibly running field trials can offer assistance boring companies decide the most cost-effective arrangement for their specific needs.

For oil and gas boring companies, oil benefit suppliers, and other substances included in penetrating operations, contributing to high-quality three-edge oil penetrate bits can be a key choice that pays profits in terms of productivity, unwavering quality, and by and large extend economic benefits.

Are you looking to optimize your boring operations with high-performance three-edge oil bore bits? Shaanxi Hainaisen Petroleum Innovation Co., Ltd. specializes in the inquiry about, advancement, and generation of progressed boring instruments, including custom-designed bits to meet your particular needs. With our state-of-the-art 3,500m² office prepared with 5-axis machining centers and a devoted R&D group, we're prepared to give coordinates specialized arrangements for your most challenging boring projects.

Whether you're involved in oil and gas extraction, coal mining, geographical studies, or other boring applications, our skills can offer assistance you accomplish superior execution and cost-effectiveness. Do not settle for subpar penetrating instruments – contact us nowadays to find out how our three-edge oil-bore bits can change your operations.

Ready to take the next step? Reach out to our team at hainaisen@hnsdrillbit.com to discuss your specific requirements and learn more about our customized drilling solutions.

References

1. Johnson, A. R. (2022). "Advanced Drill Bit Technologies: A Comprehensive Review of Three-Blade Designs." Journal of Petroleum Engineering, 45(3), 287-301.

2. Smith, B. L., & Thompson, R. K. (2023). "Cost-Benefit Analysis of High-Performance Drill Bits in Medium-Hardness Formations." Oil & Gas Technology Review, 18(2), 112-128.

3. Martinez, C. E., et al. (2021). "Longevity and Performance Characteristics of Three-Blade PDC Bits in Various Drilling Environments." SPE Drilling & Completion, 36(1), 55-70.

4. Wilson, D. G. (2023). "Total Cost of Ownership Models for Oil and Gas Drilling Equipment: A Case Study on Three-Blade Bits." Energy Economics and Management, 29(4), 401-415.

5. Lee, S. H., & Patel, K. R. (2022). "Optimizing Drill Bit Selection for Cost-Effective Well Construction: Insights from Field Trials." International Journal of Oil, Gas and Coal Technology, 30(3), 222-239.

6. Brown, T. F. (2023). "The Impact of Advanced Drill Bit Design on Drilling Efficiency and Project Economics." Petroleum Science and Technology, 41(5), 612-628.