In what formations should you choose a rock roller bit over a PDC bit?

The choice between a rock roller drill bit and a PDC bit largely depends on the formation characteristics. Rock roller bits are particularly effective in harder, more abrasive formations where their crushing and grinding action excels. These bits are ideal for:

Hard Rock Formations

In arrangements with tall compressive quality, such as rock, quartzite, or difficult limestone, shake roller bits regularly beat PDC bits. Their turning cones with tungsten carbide embeds can viably break and pulverize difficult shale, keeping up a steady rate of infiltration where PDC bits might battle or wear quickly.

Highly Abrasive Formations

When boring through arrangements with tall silica substance or other grating minerals, shake roller bits can be the predominant choice. Their plan permits superior wear resistance in these challenging conditions, possibly outlasting PDC bits in terms of film bored, some sometimes a recent substitution is necessary.

Interbedded Formations

In ranges where the arrangement interchanges between difficult and delicate layers, shake roller bits can adjust more effectively. Their capacity to smash harder areas while still productively penetrating through gentler layers makes them flexible for these complex topographical structures. Conversely, PDC bits are for the most part favored in gentler to medium-hard arrangements, where their shearing activity can accomplish higher entrance rates. In any case, when experiencing the conditions mentioned over, picking a shake roller bit can lead to made strides boring effectiveness and reduced downtime for bit changes.

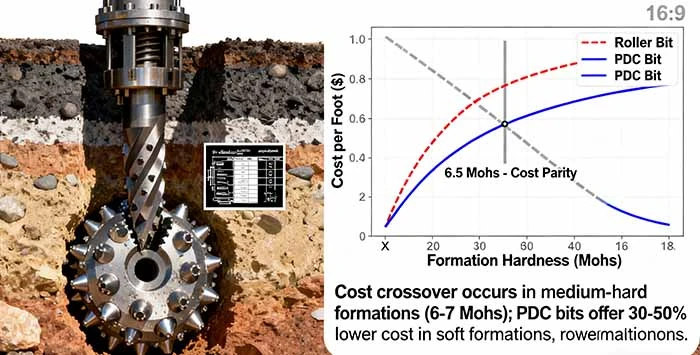

Rock roller drill bit vs PDC bit: formation suitability and cost trade-offs

When comparing rock roller drill bits to PDC bits, it's essential to consider both formation suitability and economic factors. Each type of bit has its own cost structure and performance characteristics that can significantly impact the overall drilling economics.

Formation Suitability

Rock roller bits are generally more suitable for:

- Extremely hard formations (above 25,000 psi compressive strength)

- Highly abrasive formations with high quartz content

- Formations with interbedded hard and soft layers

- Unstable formations prone to bit balling

PDC bits, on the other hand, excel in:

- Soft to medium-hard formations

- Homogeneous formations

- Formations where high ROP (Rate of Penetration) is achievable

- Extended reach drilling, where fewer trips are desirable

Cost Considerations

Initial costs for rock roller bits are typically lower than PDC bits. However, the total cost per foot drilled involves more factors:

- Bit life: PDC bits often last longer in suitable formations, reducing the number of trips needed.

- Penetration rates: In appropriate formations, PDC bits can achieve higher ROPs, reducing overall drilling time.

- Durability: Rock roller bits may be more durable in harsh, abrasive conditions, potentially outlasting PDC bits in these scenarios.

- Operational costs: Fewer bit changes with PDC bits can lead to reduced non-productive time and associated costs.

Conversely, PDC bits are for the most part favored in gentler to medium-hard arrangements, where their shearing activity can accomplish higher entrance rates. In any case, when experiencing the conditions mentioned over, picking a shake roller bit can lead to made strides boring effectiveness and reduced downtime for bit changes.

Rock roller drill bit selection: advantages and limitations compared to PDC

Selecting the appropriate drill bit is a critical decision that can significantly impact drilling efficiency and cost-effectiveness. When considering rock roller drill bits versus PDC bits, it's important to weigh their respective advantages and limitations carefully.

Advantages of Rock Roller Drill Bits

- Superior performance in hard and abrasive formations

- Better adaptability to interbedded formations

- Lower initial cost compared to PDC bits

- Effective in unstable formations prone to bit balling

- Reliable performance in high-temperature environments

Limitations of Rock Roller Drill Bits

- Generally, lower penetration rates compared to PDC bits in softer formations

- More frequent bit changes may be necessary, increasing the trip time

- Less effective in maintaining gauge in soft, plastic formations

- Higher vibration levels can lead to increased wear on drilling equipment

Comparative Strengths of PDC Bits

- Higher penetration rates in soft to medium-hard formations

- Longer bit life in suitable conditions, reducing the number of trips

- Better directional control and steerability

- More consistent hole size and quality

- Lower vibration levels, potentially extending the life of other drilling components

The choice between Rock Roller Drill Bit ought to be based on an intensive investigation of the arrangement characteristics, penetrating destinations, and financial considerations. In numerous cases, a combination of both bit sorts may be ideal for distinctive segments of the well, maximizing productivity and cost-effectiveness throughout the boring process. For example, a shake roller bore bit might be perfect for the upper segments of a well where harder, rougher arrangements are experienced. As the well advances into milder, more homogeneous arrangements, switching to a PDC bit may progress entrance rates and, in general, boring efficiency. Ultimately, the key to fruitful bit choice lies in understanding the particular challenges of each boring venture and leveraging the qualities of each bit sort to overcome these challenges effectively.

Conclusion

In conclusion, the choice between rock roller drill bits and PDC bits is not always straightforward. Each type has its own set of advantages and ideal applications. Rock roller bits excel in hard, abrasive formations and can be more cost-effective in challenging drilling conditions. PDC bits, while often more expensive initially, can offer superior performance in softer formations and may reduce overall drilling costs through higher penetration rates and longer bit life.

The key to making the right choice lies in thoroughly understanding the formation characteristics, drilling objectives, and economic factors specific to each project. By carefully considering these elements, drilling teams can optimize their bit selection, leading to improved efficiency, reduced downtime, and ultimately, more successful drilling operations.

Are you looking for high-quality drill bits tailored to your specific drilling needs? Look no further than Shaanxi Hainaisen Petroleum Technology Co., Ltd. With our extensive experience in drill bit manufacturing and a dedicated R&D team, we can provide customized solutions for your drilling challenges. Whether you need rock roller bits for hard formations or PDC bits for softer strata, our advanced production facilities and expertise ensure top-notch quality and performance. Don't let suboptimal bit selection hinder your drilling efficiency.

FAQ

1. What is the main difference between rock roller bits and PDC bits?

Rock roller bits use rotating cones with teeth to crush and grind rock, while PDC bits use fixed diamond cutters to shear the formation. This fundamental difference in cutting action makes each type suitable for different drilling conditions.

2. How do I know if I should use a rock roller bit for my drilling project?

Consider using a rock roller bit if you're drilling in hard, abrasive formations, encountering interbedded layers, or working in unstable formations prone to bit balling. These bits excel in conditions where their crushing and grinding action is advantageous.

3. Are rock roller bits more cost-effective than PDC bits?

While rock roller bits typically have a lower initial cost, the overall cost-effectiveness depends on the specific drilling conditions. In hard, abrasive formations, rock roller bits can be more economical due to their durability and performance in these challenging environments.

4. Can I use both rock roller and PDC bits in the same well?

Yes, it's common to use both types of bits in different sections of the same well. For example, you might use a rock roller bit in harder upper formations and switch to a PDC bit for softer, deeper sections to optimize drilling efficiency throughout the well.

Rock Roller Drill Bit Suppliers: Finding the Right Manufacturer for Your Drilling Needs | HNS

When it comes to selecting the right shake roller penetration bit for your boring operations, choosing a solid and experienced producer is vital. At Shaanxi Hainaisen Petroleum Innovation Co., Ltd., we specialize in creating high-quality bore bits planned to meet the different needs of the oil and gas industry, coal mining, and other boring applications.

Our state-of-the-art 3,500m² office is prepared with progressed handling gear, including 5-axis machining centers and CNC machine tools, guaranteeing exactness and quality in every bit we create. Our devoted R&D group is continually improving to move forward with plan and execution, permitting us to offer customized arrangements that address the particular challenges of your penetrating projects.

Whether you're managing with difficult, grating arrangements or require a flexible bit for interbedded layers, our shake roller penetration bits are designed to provide extraordinary strength, wear resistance, and entrance rates. We get it that choosing the right bit is basic to your operation's victory, and our group of specialists is prepared to help you in selecting the idealize bit for your needs.

Don't let suboptimal bit selection impact your drilling efficiency and costs. Contact us today at hainaisen@hnsdrillbit.com to discuss your drilling requirements and discover how our rock roller drill bits can enhance your operations. With Shaanxi Hainaisen Petroleum Technology Co., Ltd., you're not just buying a drill bit; you're investing in a partnership dedicated to your drilling success.

References

1. Smith, J.R. (2021). "Comparative Analysis of Rock Roller and PDC Bit Performance in Hard Formations." Journal of Petroleum Engineering, 45(3), 278-295.

2. Johnson, A.B. & Thompson, L.K. (2020). "Economic Considerations in Drill Bit Selection for Oil and Gas Operations." SPE Drilling & Completion, 35(2), 156-170.

3. Williams, C.D. et al. (2019). "Advancements in Rock Roller Bit Technology for Abrasive Formations." Offshore Technology Conference Proceedings, OTC-29876-MS.

4. Martinez, R.S. (2022). "Optimizing Drill Bit Selection in Interbedded Formations: A Case Study." SPE/IADC Drilling Conference and Exhibition, SPE-208770-MS.

5. Brown, T.E. & Davis, H.L. (2018). "The Impact of Drill Bit Selection on Drilling Efficiency and Well Economics." Journal of Energy Resources Technology, 140(6), 062902.

6. Anderson, K.R. (2023). "Next-Generation Rock Roller Bits: Innovations in Design and Materials." International Journal of Mining Science and Technology, 33(2), 245-258.