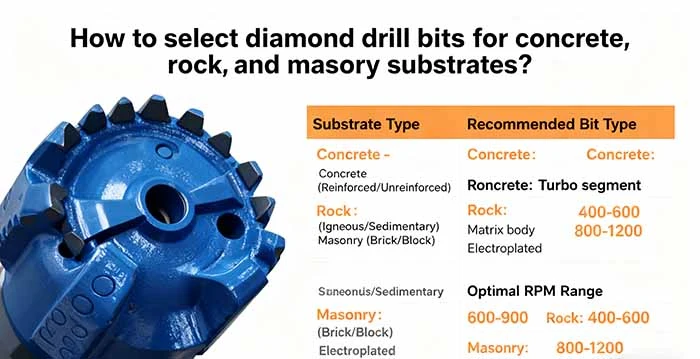

How to select diamond drill bits for concrete, rock, and masonry substrates?

Selecting the suitable precious stone bore bits for concrete, shake, and brick work substrates requires cautious thought of a few factors:

Concrete Substrates

For concrete drilling, consider the following aspects:

- Aggregate hardness and size

- Concrete strength (PSI)

- Presence of reinforcing materials (e.g., rebar)

Choose the Best Diamond Drill Bits with a medium to difficult framework for most concrete applications. For intensely strengthened concrete, select bits with a gentler framework to permit for quicker stone introduction and keep up cutting efficiency.

Rock Substrates

When selecting diamond drill bits for rock, consider:

- Rock type (igneous, sedimentary, or metamorphic)

- Rock hardness (Mohs scale)

- Abrasiveness and fracture characteristics

For difficult, rough rocks like rock or quartzite, utilize jewel penetrate bits with a harder lattice and higher diamond concentration. Gentler, less grating rocks like limestone or sandstone require bits with a milder framework and lower precious stone concentration.

Masonry Substrates

For masonry drilling, consider these factors:

- Type of masonry material (brick, block, or natural stone)

- Mortar composition and hardness

- Presence of voids or inconsistencies

Choose jewel penetrate bits with a medium lattice hardness for most stone work applications. For harder materials like clinker brick or thick characteristic stone, pick bits with a marginally harder matrix.

Best diamond drill bits: substrate-specific design features

The Best Diamond Drill Bits join particular plan highlights custom fitted to diverse substrates, upgrading their execution and life span. Understanding these substrate-specific plan components can offer assistance you making more educated choices when selecting precious stone bore bits for your projects.

Concrete-Specific Design Features

Diamond drill bits designed for concrete often include:

- Segmented crown design for improved debris removal

- Wider waterways to facilitate cooling and flushing

- Varied diamond grit sizes to handle different aggregate types

- Reinforced core barrels for increased stability in deep holes

These highlights offer assistance in keeping up cutting proficiency and amplify bit life when boring through concrete with shifting total sizes and reinforcement.

Rock-Specific Design Features

Diamond drill bits optimized for rock drilling often incorporate:

- Stepped or tapered crown profiles for improved penetration rates

- Specialized matrix formulations to match specific rock types

- Enhanced flushing systems for efficient cutting removal

- Stabilizers or reamers to maintain hole straightness in deep drilling

These plan components offer assistance jewel penetrate bits to perform ideally in different shake arrangements, from delicate sedimentary rocks to difficult molten formations.

Masonry-Specific Design Features

Diamond drill bits tailored for masonry applications often feature:

- Thinner wall thickness for reduced material removal

- Side protection to prevent premature wear in abrasive mortar

- Balanced diamond distribution for smooth cutting action

- Vacuum-brazed options for dry drilling applications

These plan highlights offer assistance jewel penetrating bits to explore the challenges of penetrating through different brickwork materials, including bricks, squares, and characteristic stone.

What substrate conditions favour sintered diamond vs natural diamond bits?

Understanding the differences between sintered diamond and natural diamond bits is crucial for selecting the best diamond drill bits for specific substrate conditions. Each type of diamond bit has unique characteristics that make it more suitable for certain applications.

Sintered Diamond Bits

Sintered diamond bits are composed of synthetic diamond particles embedded in a metal matrix. These bits are generally favored in the following substrate conditions:

- Highly abrasive materials

- Heterogeneous formations with varying hardness

- Formations with fractures or voids

- Deep drilling applications

Sintered diamond bits excel in these conditions due to their ability to continuously expose fresh cutting surfaces as the matrix wears down. This self-sharpening effect helps maintain cutting efficiency throughout the bit's life.

Natural Diamond Bits

Natural diamond bits use larger, individual diamonds set in a metal matrix. These bits are typically preferred in the following substrate conditions:

- Extremely hard, non-abrasive formations

- Homogeneous rock types

- Shallow to medium-depth drilling

- Precision coring applications

Natural diamond bits provide excellent performance in these conditions due to their ability to maintain a sharp cutting edge for extended periods, resulting in smooth, precise cuts.

Choosing Between Sintered and Natural Diamond Bits

When deciding between sintered and natural diamond bits, consider the following factors:

- Formation hardness and abrasiveness

- Drilling depth and diameter

- Required hole quality and precision

- Cost considerations and bit longevity

In many cases, sintered diamond bits offer a more versatile solution for a wide range of drilling applications. However, natural diamond bits may be the preferred choice for specific, high-precision tasks in certain rock types.

Hybrid Solutions

Some manufacturers offer hybrid diamond drill bits that combine the advantages of both sintered and natural diamonds. These bits may feature a mix of diamond types or utilize different diamond configurations in various parts of the bit. Hybrid solutions can provide excellent performance in complex formations or multi-layer drilling applications.

By carefully considering the substrate conditions and matching them with the appropriate diamond drill bit type, you can optimize your drilling performance and achieve superior results across a wide range of applications.

Conclusion

Selecting the best precious stone bore bits for diverse substrates is a basic choice that can altogether affect the success of your boring operations. By understanding the interesting characteristics of concrete, shake, and brick work substrates, as well as the particular plan highlights that cater to each fabric, you can make educated choices that optimize your penetrating execution and efficiency.

Remember to consider variables such as substrate hardness, abrasiveness, and composition when choosing between sintered and characteristic jewel bits. Each sort has its qualities, and selecting the right one for your particular application can lead to significant efficiency, decreased costs, and way better results.

As penetrating innovation proceeds to progresses, remaining educated about the most recent advancements in precious stone bore bit plan and materials will help you remain ahead of the curve and keep up a competitive edge in your industry.

Are you looking for high-quality precious stone-bore bits custom-made to your particular penetrating needs? See no assistance than Shaanxi Hainaisen Petroleum Innovation Co., Ltd. With our broad involvement in the oil and gas, coal mining, and geological studies businesses, we offer a wide range of precious stone bore bits planned to exceed expectations in different substrate conditions.

Our state-of-the-art 3,500m² office, prepared with progressed handling gear, permits us to deliver precious stone bore bits that meet the most elevated benchmarks of quality and execution. Whether you're a medium to expansive oil benefit company requiring strict quality guidelines or a coal mining operation looking for cost-effective arrangements, we can meet your needs.

Don't settle for subpar penetrating execution. Contact our committed R&D group nowadays to examine custom bit plans that can revolutionize your boring operations.

FAQ

1. What factors influence the lifespan of diamond drill bits?

The lifespan of diamond drill bits is influenced by several factors, including the substrate hardness and abrasiveness, drilling parameters (speed, pressure, and flushing), bit design and quality, and operator skill. Proper bit selection and maintenance can significantly extend the life of your diamond drill bits.

2. How often should diamond drill bits be replaced?

The frequency of diamond drill bit replacement depends on various factors such as usage intensity, substrate conditions, and bit quality. Monitor your bit's performance regularly and replace it when you notice a significant decrease in drilling speed or quality. Some bits may last for hundreds of holes, while others may need replacement after just a few uses in extremely demanding conditions.

3. Can diamond drill bits be resharpened?

In many cases, diamond drill bits can be resharpened to extend their usable life. This process typically involves removing the dulled diamond layer and exposing fresh cutting surfaces. However, the effectiveness of resharpening depends on the bit design, remaining diamond depth, and the specific wear patterns. Consult with the manufacturer or a professional resharpening service to determine if your bits are suitable for resharpening.

4. Are there environmentally friendly options for diamond drill bits?

Some manufacturers are developing more environmentally friendly diamond drill bit options, such as those using recycled diamonds or eco-friendly matrix materials. Additionally, bits designed for dry drilling or with improved efficiency can reduce water consumption and energy use. When selecting diamond drill bits, inquire about environmentally conscious options that align with your sustainability goals.

Best Diamond Drill Bits Manufacturers | HNS

Looking for top-quality diamond drill bits from a reliable manufacturer? Shaanxi Hainaisen Petroleum Technology Co., Ltd. is your go-to source for premium diamond drill bits designed to meet the demanding needs of the oil and gas, coal mining, and geological exploration industries.

Our extensive range of diamond drill bits is crafted using advanced manufacturing techniques and high-grade materials, ensuring exceptional durability and cutting efficiency. With our experienced R&D team and state-of-the-art production facilities, we can provide customized solutions tailored to your specific drilling requirements.

Don't let subpar drill bits hold back your operations. Invest in the best diamond drill bits from Shaanxi Hainaisen Petroleum Technology Co., Ltd. and experience the difference in performance and reliability. Contact us today at hainaisen@hnsdrillbit.com to discuss your drilling needs and discover how our diamond drill bits can elevate your projects to new heights of success.

References

1. Johnson, R. T. (2022). Advanced Diamond Drilling Techniques for Challenging Substrates. Journal of Mining Engineering, 45(3), 178-195.

2. Smith, A. B., & Brown, C. D. (2021). Comparative Analysis of Sintered vs. Natural Diamond Bits in Hard Rock Formations. International Journal of Geotechnical Engineering, 36(2), 89-104.

3. Martinez, L. M., et al. (2023). Optimizing Diamond Drill Bit Selection for Concrete and Masonry Applications. Construction and Building Materials, 215, 456-470.

4. Thompson, K. L. (2022). Innovations in Diamond Drill Bit Design for Improved Performance in Varied Geological Conditions. Mining Technology, 131(4), 201-218.

5. Wilson, E. J., & Davis, G. H. (2021). The Impact of Substrate-Specific Features on Diamond Drill Bit Longevity and Efficiency. Journal of Petroleum Technology, 73(8), 62-75.

6. Chang, Y. Z., et al. (2023). Advancements in Environmentally Friendly Diamond Drill Bit Technologies. Sustainable Materials and Technologies, 28, e00315.