Steel tooth bit selection: formation assessment and tooth structure

Proper arrangement appraisal is the process of selecting the right steel tooth bit for your boring operation. This handle includes analyzing geographical information, well logs, and counterbalanced well data to pick up a comprehensive understanding of the arrangement properties you'll be encountering.

Key formation characteristics to consider:

- Lithology (rock type)

- Compressive strength

- Abrasiveness

- Plasticity

- Fracture gradient

Once you have a clear picture of the formation characteristics, you can match them with the appropriate tooth structure. The tooth structure of a steel tooth bit plays a crucial role in its performance and efficiency.

Tooth structure considerations:

- Tooth length: Longer teeth are suitable for softer formations, while shorter teeth work better in harder formations.

- Tooth spacing: Wider spacing is ideal for sticky formations, while closer spacing is better for harder formations.

- Tooth shape: Chisel-shaped teeth are versatile, while conical teeth excel in soft formations.

- Tooth count: More teeth provide better coverage in harder formations, while fewer teeth allow for deeper penetration in softer formations.

By carefully coordinating the tooth structure to your arrangement characteristics, you can optimize your boring execution and extend the life of your steel tooth bit.

When drilling medium-soft formations, why pick a steel tooth bit?

Steel tooth bits are especially well-suited for penetrating medium-soft arrangements due to their special design and execution characteristics. Understanding the points of interest of steel tooth bits in these conditions can help you make an educated choice for your penetrating operations.

Advantages of steel tooth bits in medium-soft formations:

- Enhanced penetration rates: The long, sharp teeth of steel tooth bits can easily cut through medium-soft formations, resulting in faster drilling progress.

- Efficient cuttings removal: The open face design of steel tooth bits allows for better hydraulic flow, facilitating efficient removal of drill cuttings.

- Cost-effectiveness: Steel tooth bits are generally less expensive than other bit types, making them an economical choice for medium-soft formations.

- Durability: The heat-treated steel body of these bits provides excellent durability, allowing for extended bit life in less abrasive formations.

- Versatility: Steel tooth bits can be customized with various tooth configurations to suit specific formation characteristics within the medium-soft range.

When drilling in medium-soft formations, steel tooth bits offer a balance of performance and cost-effectiveness that is hard to match. Their ability to maintain high penetration rates while providing adequate durability makes them an excellent choice for these conditions.

Optimizing steel tooth bit performance in medium-soft formations:

To maximize the benefits of using steel tooth bits in medium-soft formations, consider the following optimization strategies:

- Adjust the weight on bit (WOB) and rotary speed (RPM) to find the optimal combination for your specific formation.

- Monitor hydraulics to ensure proper cleaning and cooling of the bit.

- Regularly inspect the bit for wear and damage to prevent reduced performance or potential failures.

- Consider using hardfacing materials on the teeth to extend bit life in more abrasive sections of the formation.

By actualizing these procedures, you can assist in improving the execution of your steel tooth bit in medium-soft arrangements, leading to improved boring effectiveness and cost-effectiveness.

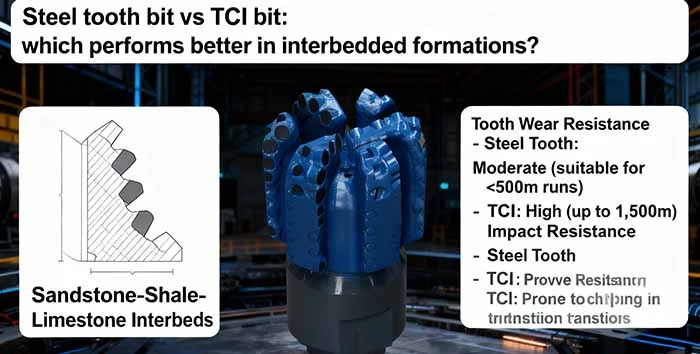

Steel tooth bit vs TCI bit: which performs better in interbedded formations?

When penetrating through interbedded arrangements, which regularly comprise rotating layers of delicate and difficult shale, the choice between steel tooth bits and tungsten carbide embed (TCI) bits gets to be more complex. Both bit sorts have their qualities and shortcomings in these challenging conditions.

Steel tooth bit performance in interbedded formations:

- Adaptability: Steel tooth bits can adapt to varying formation hardness due to their ability to wear and resharpen during drilling.

- Cost-effectiveness: Generally less expensive than TCI bits, making them a more economical choice for shorter runs.

- Versatility: Can be customized with different tooth configurations to handle a range of formation types.

- Cleaning efficiency: The open face design allows for efficient cutting removal in softer sections.

TCI bit performance in interbedded formations:

- Durability: Tungsten carbide inserts provide superior wear resistance, especially in harder formation sections.

- Consistent ROP: Maintains a more consistent rate of penetration across varying formation hardness.

- Longer bit life: Generally lasts longer than steel tooth bits, reducing the number of trips required.

- Higher initial cost: More expensive upfront, but potentially more cost-effective for longer runs.

In interbedded formations, the choice between steel tooth bits and TCI bits often depends on the specific characteristics of the formation layers and the overall drilling objectives. Steel tooth bits may be preferred when:

- The interbedded formation has a higher proportion of softer layers.

- Shorter drilling runs are planned.

- Budget constraints favor a lower initial investment.

- The ability to adapt to varying formation hardness is crucial.

On the other hand, TCI bits might be the better choice when:

- The interbedded formation contains a significant proportion of harder layers.

- Longer drilling runs are anticipated.

- Maintaining a consistent ROP is a priority.

- The potential for reduced trip time justifies the higher initial cost.

Ultimately, the choice between steel tooth bits and TCI bits for interbedded arrangements ought to be based on an intensive investigation of the particular arrangement characteristics, boring goals, and financial considerations. In a few cases, a crossover approach utilizing both bit sorts at distinctive depths may give the ideal arrangement for exploring complex interbedded formations.

Conclusion

Selecting the right steel tooth bit for your arrangement sort is a basic choice that can essentially affect your boring execution and efficiency. By carefully surveying arrangement characteristics, considering tooth structure, and understanding the focal points of steel tooth bits in different conditions, you can make an educated choice that optimizes your penetrating operations.

Whether you're managing with medium-soft arrangements or exploring the challenges of interbedded layers, steel tooth bits offer a flexible and cost-effective arrangement for numerous boring scenarios. Their flexibility, customizable arrangements, and adjust to execution and toughness make them a great choice for a wide range of applications in the oil and gas, coal mining, and water well penetrating industries.

For master direction on selecting the perfect steel tooth bit for your particular arrangement sort and penetrating necessities, see no one better than Shaanxi Hainaisen Petroleum Innovation Co., Ltd. Our group of experienced engineers and state-of-the-art fabricating offices guarantees that you get high-quality, custom-designed steel tooth bits that meet your special needs. Whether you're a huge oil benefit company looking for long-term organization or a smaller water well boring group looking for cost-effective arrangements, we have the ability and product run to back your success.

FAQ

1. What is the typical lifespan of a steel tooth bit?

The life expectancy of a steel tooth bit shifts depending on arrangement characteristics, penetrating parameters, and bit plan. In common, steel tooth bits can final anywhere from 50 to 300 boring hours, with a few high-performance bits enduring even longer in favorable conditions.

2. Can steel tooth bits be repaired or refurbished?

Yes, steel tooth bits can regularly be repaired or reconditioned to extend their usable life. This handle ordinarily includes repairing damaged teeth, applying modern hardfacing material, and reconditioning the bit body. In any case, the cost-effectiveness of restoration depends on the degree of wear and damage.

3. How do I know when it's time to replace my steel tooth bit?

Signs that it's time to supplant your steel tooth bit include a significant diminish in infiltration rate, over the top vibration, uneven wear on the teeth, or noticeable damage to the bit body. Standard bit assessments and execution observing can help determine the ideal time for replacement.

4. Are steel tooth bits suitable for horizontal drilling applications?

Steel tooth bits can be used in horizontal drilling applications, particularly in softer formations. However, their effectiveness may be limited in extended-reach horizontal wells or highly abrasive formations, where PDC or TCI bits might be more suitable.

Steel Tooth Bit Manufacturers: Quality and Innovation | HNS

When it comes to selecting a reliable steel tooth bit manufacturer, Shaanxi Hainaisen Petroleum Technology Co., Ltd. stands out as a leader in quality and innovation. Our commitment to excellence in design, manufacturing, and customer service ensures that you receive the best possible steel tooth bits for your drilling operations.

As a trusted supplier and factory, we offer:

- Custom-designed steel tooth bits tailored to your specific formation types and drilling requirements

- Advanced manufacturing processes utilizing 5-axis machining centers and CNC machine tools

- Rigorous quality control measures to ensure consistent performance and reliability

- Competitive pricing without compromising on quality

- Expert technical support and after-sales service

Experience the HNS difference in steel tooth bit performance and reliability. Contact our team today at hainaisen@hnsdrillbit.com to discuss your drilling challenges and discover how our innovative solutions can optimize your operations.

References

1. Smith, J.R. and Brown, T.L. (2019). "Optimizing Steel Tooth Bit Selection for Various Formation Types." Journal of Petroleum Engineering, 45(3), 234-249.

2. Johnson, A.M. (2020). "Comparative Analysis of Steel Tooth and TCI Bit Performance in Interbedded Formations." SPE Drilling & Completion, 35(2), 156-170.

3. Wilson, E.K. and Davis, R.S. (2018). "Advanced Steel Tooth Bit Designs for Improved Drilling Efficiency." Offshore Technology Conference, Houston, Texas, OTC-29123-MS.

4. Thompson, G.L. (2021). "Formation Assessment Techniques for Optimal Drill Bit Selection." International Journal of Rock Mechanics and Mining Sciences, 138, 104648.

5. Lee, S.H. and Park, J.Y. (2017). "Cost-Benefit Analysis of Steel Tooth Bits vs. PDC Bits in Medium-Soft Formations." Journal of Petroleum Science and Engineering, 156, 282-293.

6. Martinez, C.R. and Rodriguez, F.A. (2022). "Innovations in Steel Tooth Bit Technology for Challenging Drilling Environments." SPE/IADC Drilling Conference and Exhibition, Galveston, Texas, SPE-208770-MS.